A prefabricated decorative wall panel assisting handling and stacking mechanism

A prefabricated, wallboard technology, applied in cleaning devices, transportation and packaging, conveyor objects, etc., can solve the problems of low labor intensity, increased transportation costs, wallboard damage, etc., to improve work sensitivity and improve performance. , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

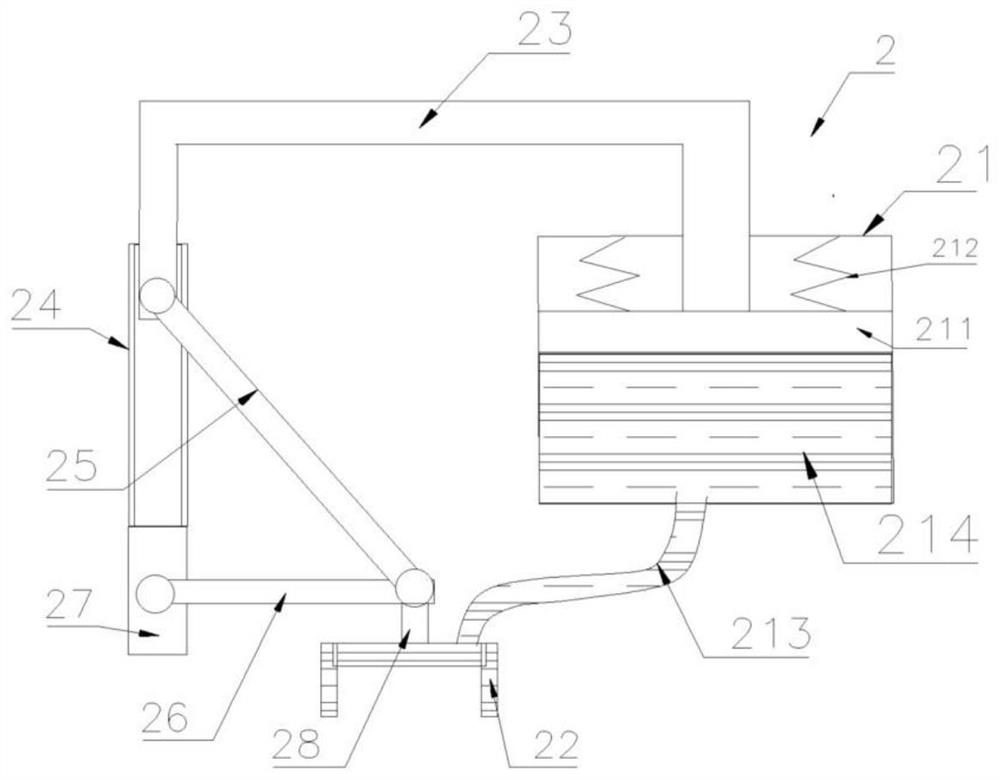

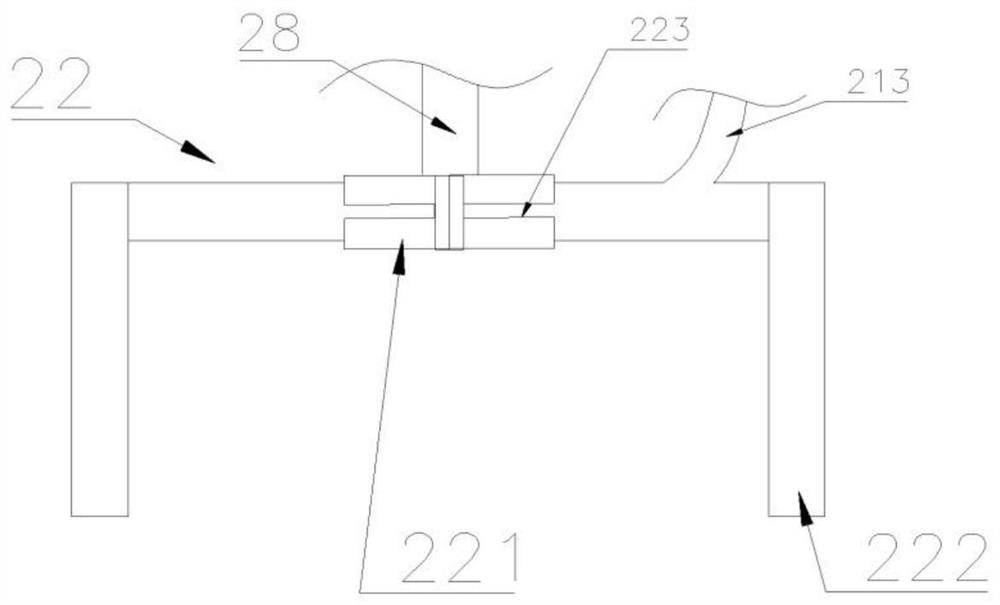

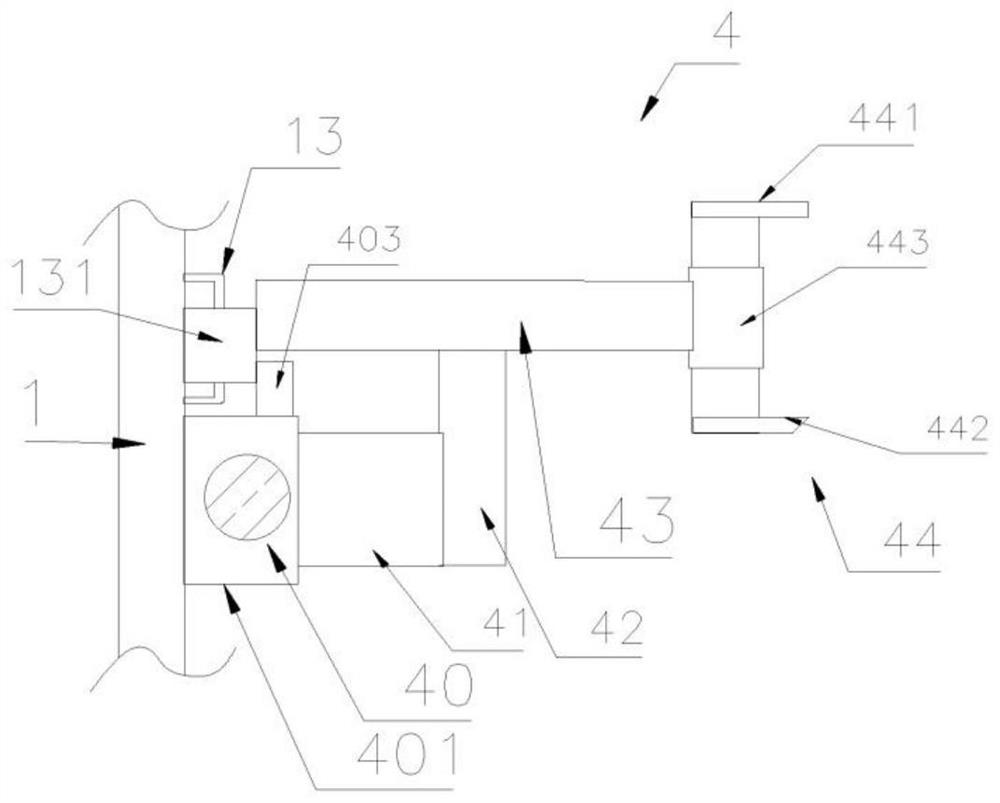

[0036] Example: see Figure 1-11 , the present invention provides a technical solution: a prefabricated decorative wallboard assisting handling and stacking mechanism, including a vehicle body 1 and a first clamping assembly 2, the first clamping assembly 2 is used to clamp the wallboard 3 and transfer it to the vehicle body 1 Above, a second clamping assembly 4 is provided inside the vehicle body 1, and the second clamping assembly 4 is used to clamp the wall panel 3 and remove it from the vehicle body; the first clamping assembly 2 can be arranged outside the vehicle body 1 as a separate assembly , so as to achieve the function of clamping the wall panel 3 and transferring it to the vehicle body 1, the first clamping assembly 2 can also be arranged on the vehicle body 1, and the fuel tank 21 can be fixed on the inner wall of the vehicle body 1, and the setting method is not limited .

[0037] The first clamping assembly 2 includes a fuel tank 21 and a first clamping hand 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com