Decorative joint structure of curtain wall sandwich panel

A sandwich panel and curtain wall technology, applied to building structures, walls, building components, etc., can solve the problems of weather-resistant sealant aging, increased cost and construction period, and lack of metal texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

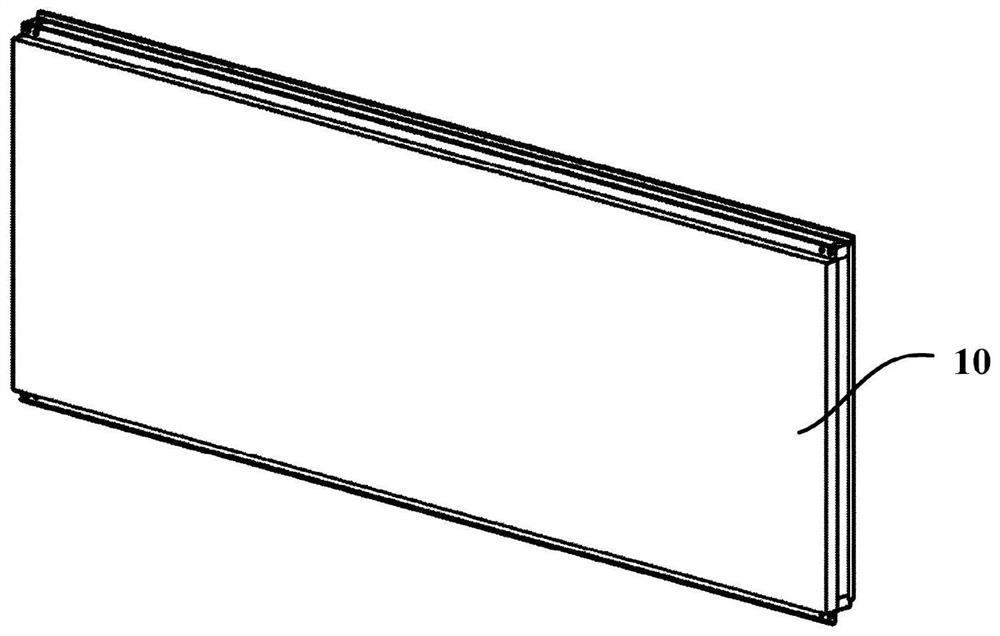

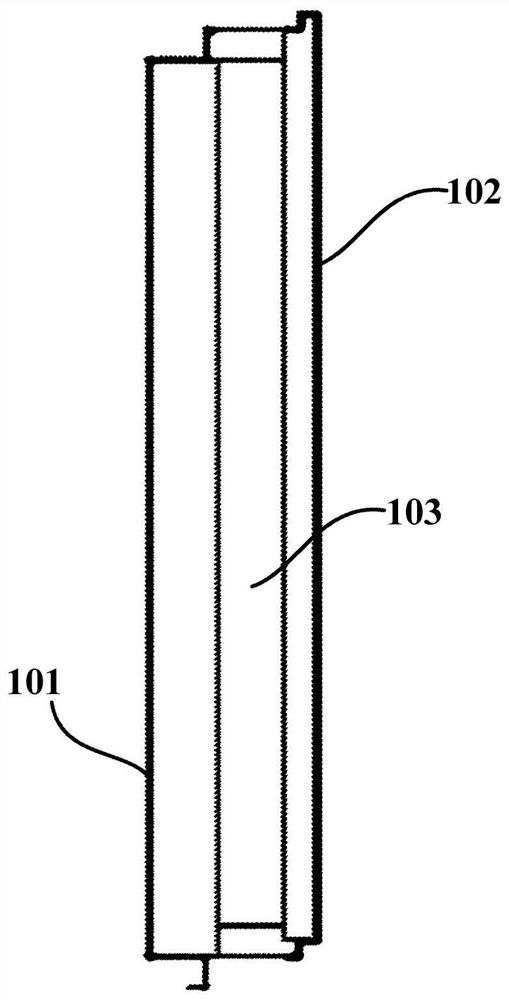

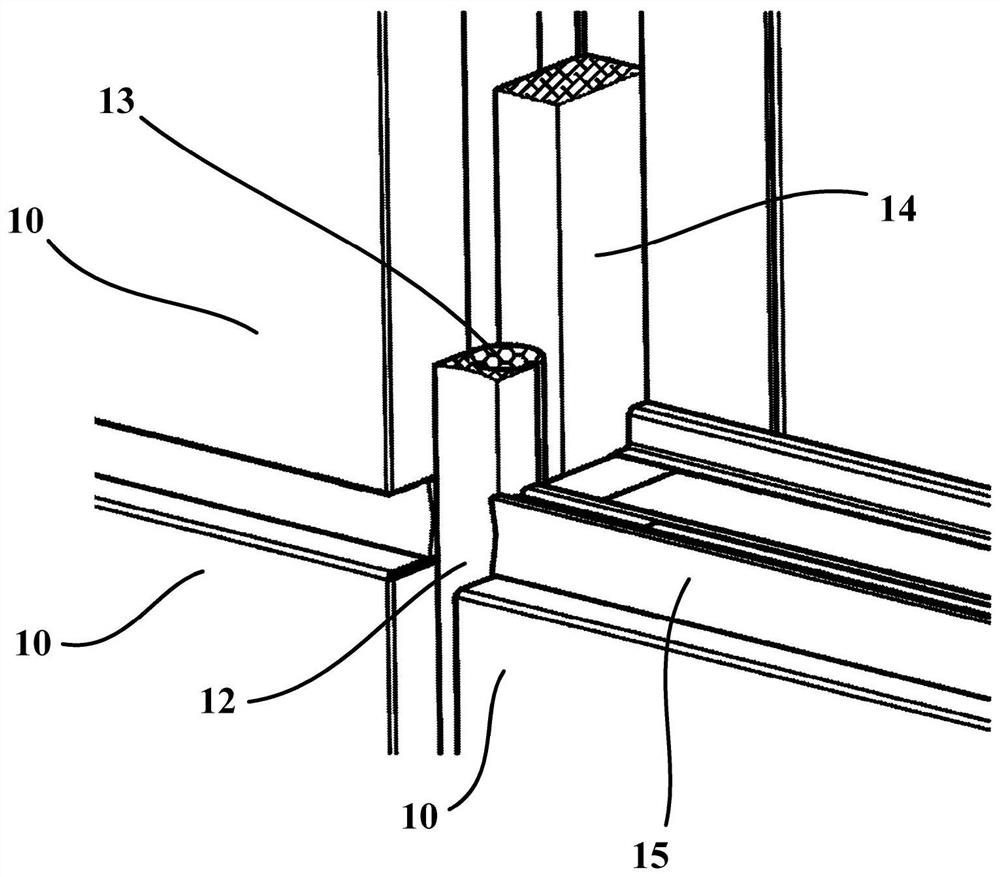

[0056] Figure 5 It is a schematic cross-sectional view of the decorative joint structure of the curtain wall sandwich panel provided by the embodiment of the present invention, such as Figure 5 shown, and refer to Figure 6 to Figure 16 , The embodiment of the present invention provides a decorative seam structure of a curtain wall sandwich panel. The curtain wall sandwich panels 10 are installed on the wall support structure 20 and arranged in multiple rows. There is a vertical gap between the left and right columns of curtain wall sandwich panels adjacent to the left and right. The upper and lower curtain wall sandwich panels in the left row of curtain wall sandwich panels are installed on the wall support structure 20 through the first installation structure. The upper and lower curtain wall sandwich panels in the right row of curtain wall sandwich panels are installed on the wall support structure 20 through the second installation structure. The decorative seam stru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com