Wall system service process simulation device

A process simulation and wall technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of single function of evaluation equipment and cannot evaluate the performance of traditional and prefabricated wall systems, and achieve the effect of optimizing evaluation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

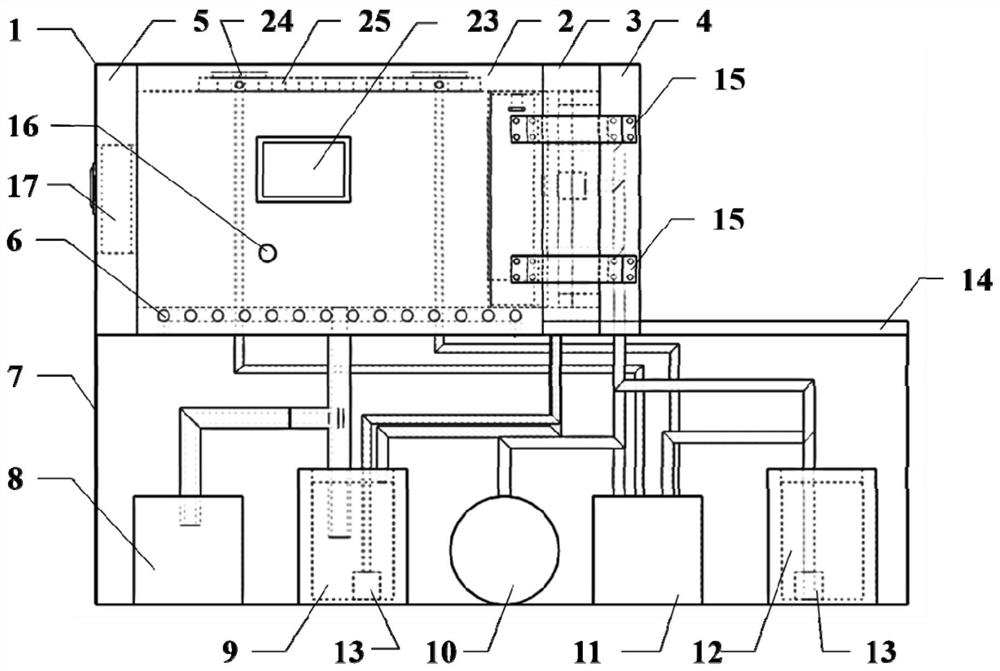

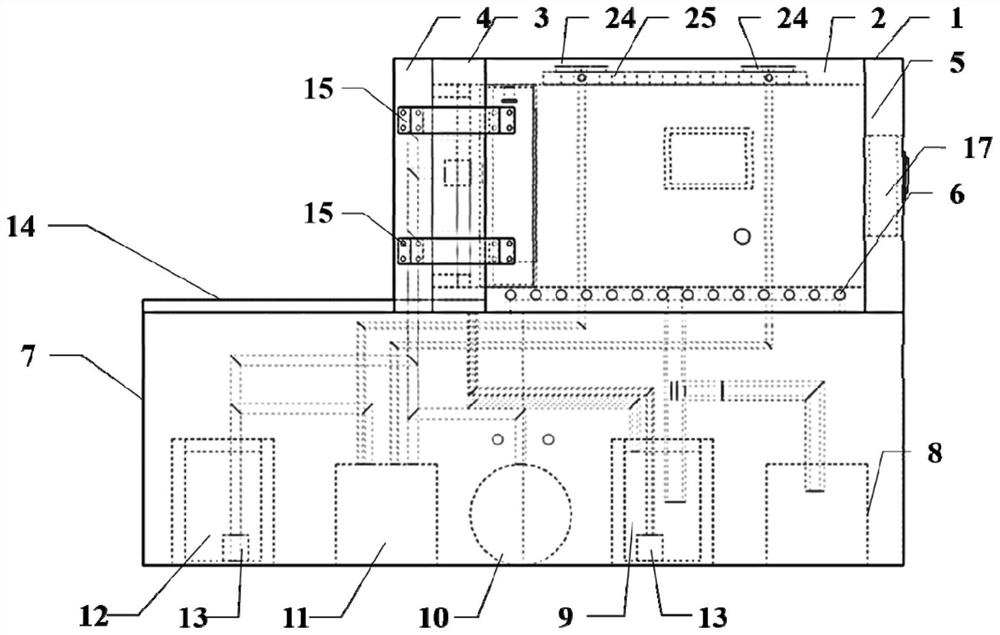

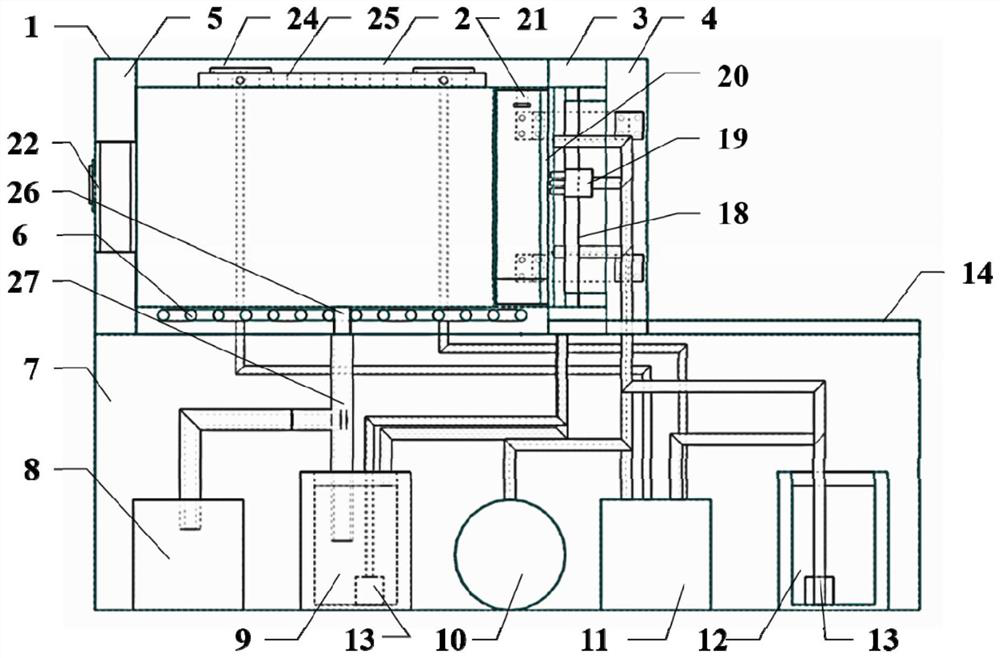

[0033] Specific implementation mode 1: In this implementation mode, a wall system service process simulation device includes:

[0034] In the present invention, terms such as "upper", "lower", "front", "rear", "left", "right", "top", "bottom", "inside", "outside", etc. ” and so on are only based on the orientation and positional relationship shown in the drawings to facilitate the description of the present invention, and do not indicate or imply that the device must have a specific orientation, so they should not be construed as limitations on the present invention.

[0035] The main body of the equipment 1, the main body of the equipment is composed of the environment simulation chamber 2, the wall system fixing bracket 3, the pressure temperature control board composite sealing door 4, the observation window sealing door 5 and the equipment box 7;

[0036] The environment simulation chamber 2, the wall system fixing bracket 3, the pressure temperature control board composit...

specific Embodiment approach 2

[0048] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the inner frame of the fixed bracket 3 of the wall system is provided with a sprinkler 21, and the sprinkler 21 is connected with the water pump 13 in the variable temperature circulating water device 9 to realize Water spraying process control on the wall.

[0049]Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0050] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the pressure temperature control plate composite airtight door 4 is combined with the wall system fixing bracket 3 along the guide rail 14;

[0051] Use buckles 15 on both sides to fix the environment simulation chamber 2, the wall system fixing bracket 3 and the pressure temperature control board composite sealing door 4 to achieve sealing.

[0052] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com