A Continuously Variable Stiffness Ball Joint Based on Pneumatics

A ball joint and stiffness technology, applied in the field of robotics, can solve the problems of low stiffness and poor bearing capacity of flexible robots, and achieve the effect of large stiffness and bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

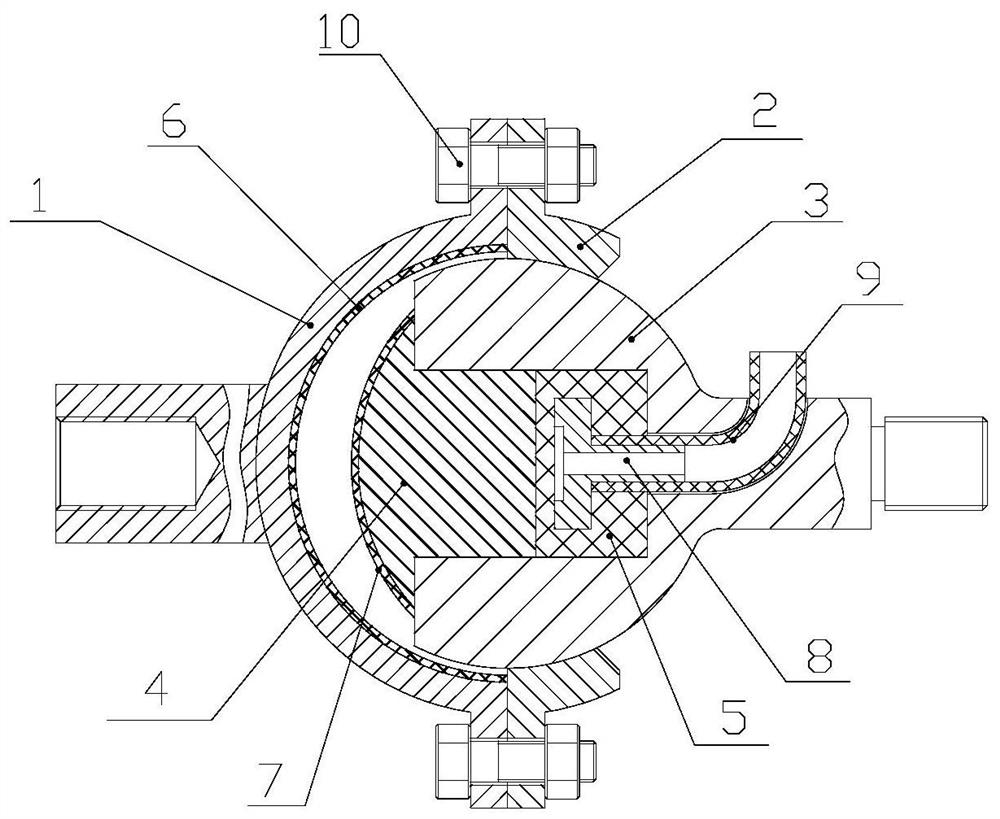

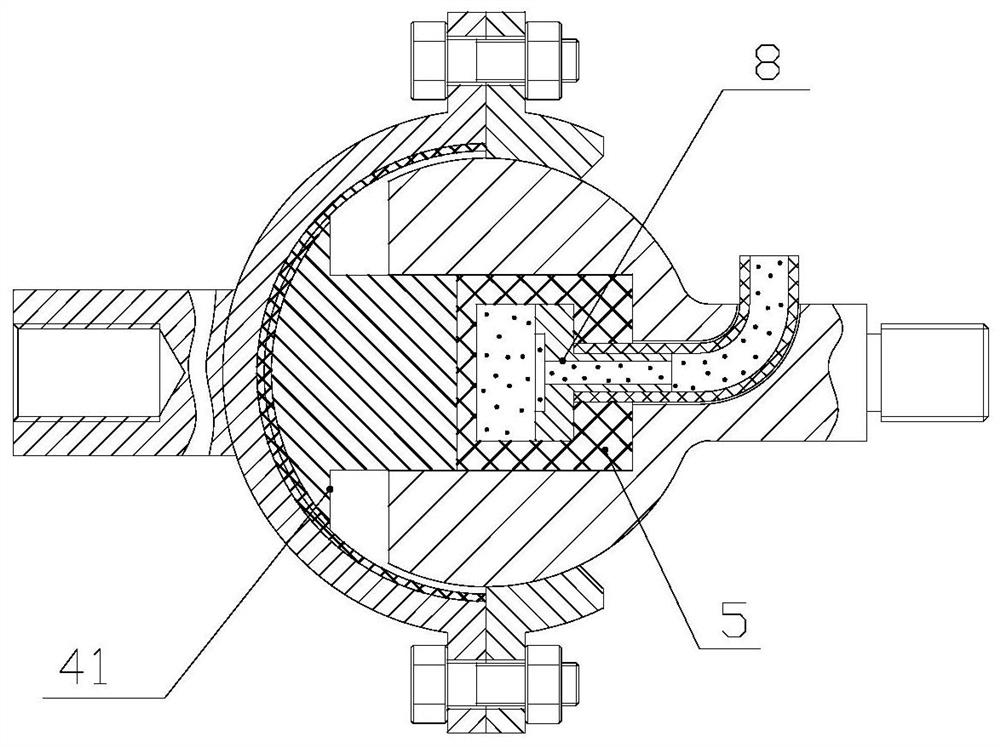

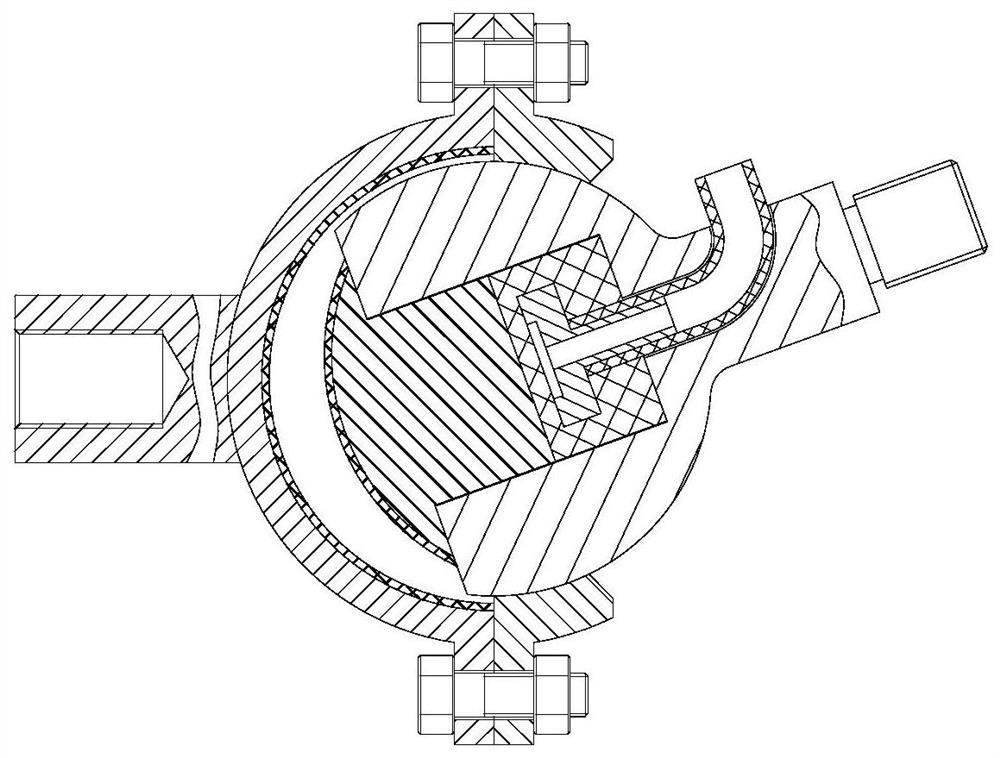

[0022] Specific implementation mode one: combine Figure 1~5 Describe this embodiment, a continuously variable stiffness ball joint based on pneumatics, which includes a left ball socket 1, a right ball socket 2, a support ball head 3, a friction ball head 4 and a silicone sealing cavity 5, wherein the left ball socket 1 It is fixedly connected with the right ball socket 2 and forms a cavity. The supporting ball head 3 is installed in the cavity in cooperation with rotation. There is a groove on the head 3, and the opening end of the groove is set towards the left ball socket 1. The silicone sealing cavity 5 is installed at the bottom of the groove, and one end of the friction ball head 4 is inserted into the groove. In the groove and in contact with the silica gel sealing cavity 5 without gaps, the shape of the other end is set along with the inner wall of the left ball socket 1. The inner wall of the left ball socket 1 is fixed with a ball socket friction layer 6, and the ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com