A conduction anti-deflection and replacement structure of a packing belt feed roller

A technology of anti-deflection and belt roller, which is applied in the direction of strapping materials, paper/cardboard containers, and parts of strapping machinery, etc. It can solve the problems of slow feeding, speed deviation, and easy lateral movement of strapping strips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

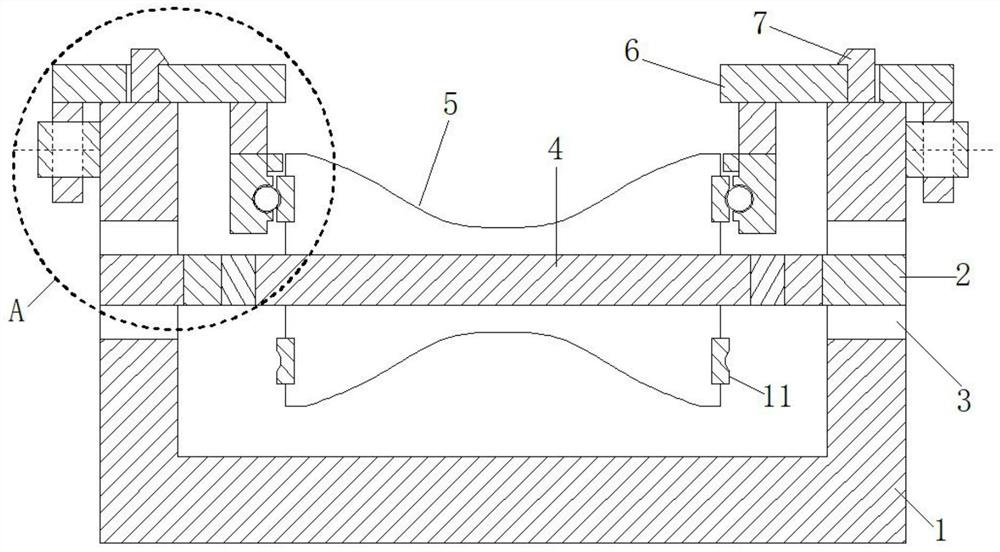

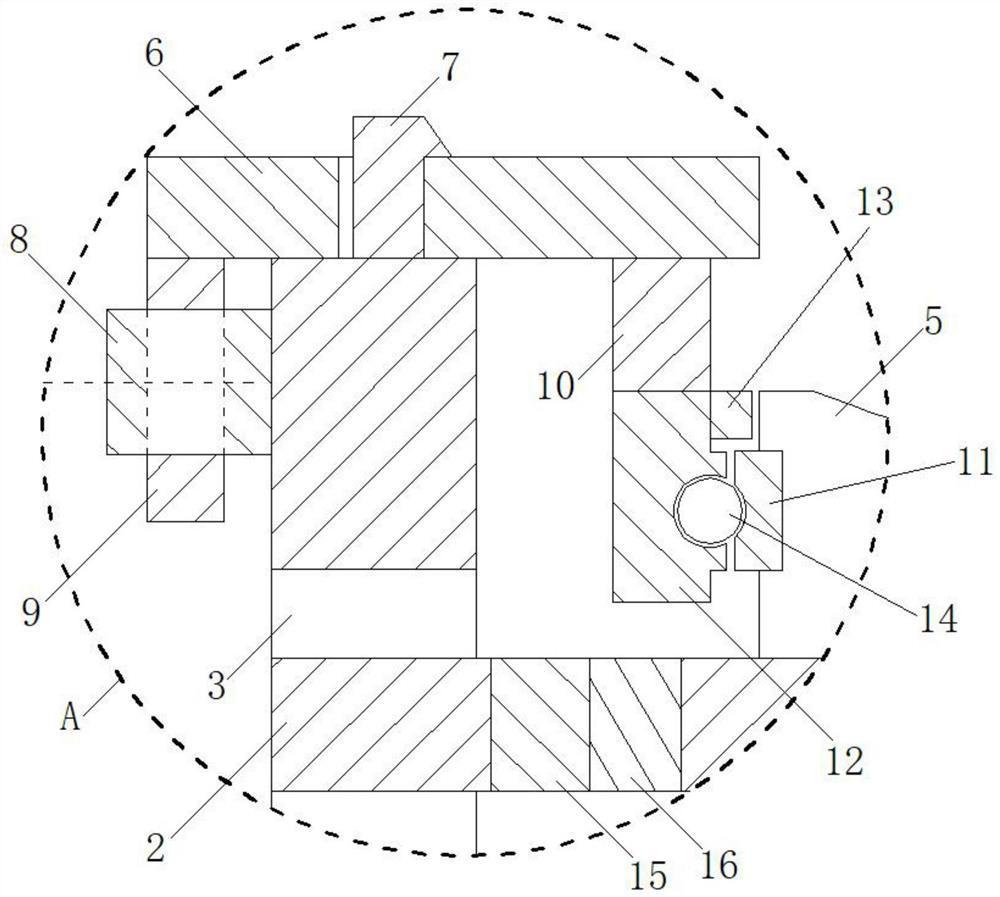

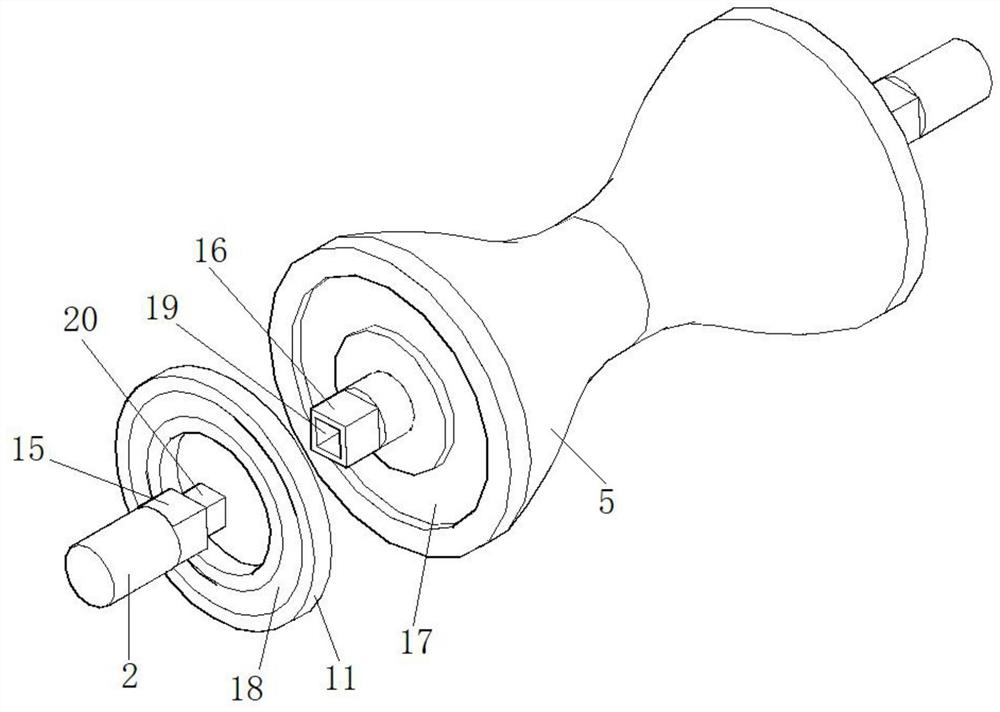

[0032] see figure 1 , figure 2 , image 3 , Figure 4 , The invention relates to a conduction anti-deflection and replacement structure of a packing belt feed roller.

[0033] In the conduction anti-deflection and replacement structure of the packing belt feed roller in the present invention: the feed roller body 5 is installed on the first base base 1, and the upper side of the vertical side plate of the first base base 1 is fixedly provided with an elastic The third buckle 7; the third installation horizontal plate 6 is provided with a through-slot structure matched with the third buckle 7 . The outer surface of the vertical side plate of the first base base 1 is fixedly provided with a base outer projection 8; the base outer projection 8 is provided with a vertical through-slot structure.

[0034] In the conduction anti-deflection and replacement structure of the packing belt feed roller in the present invention: the first installation bearing 3 is installed on the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com