Detachable battery fixing frame for new energy automobile based on sliding

A new energy vehicle and battery fixing technology, which is applied in the direction of electric vehicles, secondary batteries, battery pack components, etc., can solve the problems of endangering the driver's personal safety, reducing the service life of the battery, and inconvenient disassembly of the battery, so as to solve the inconvenience of maintenance and replacement , Improve the safe service life and improve the convenience of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

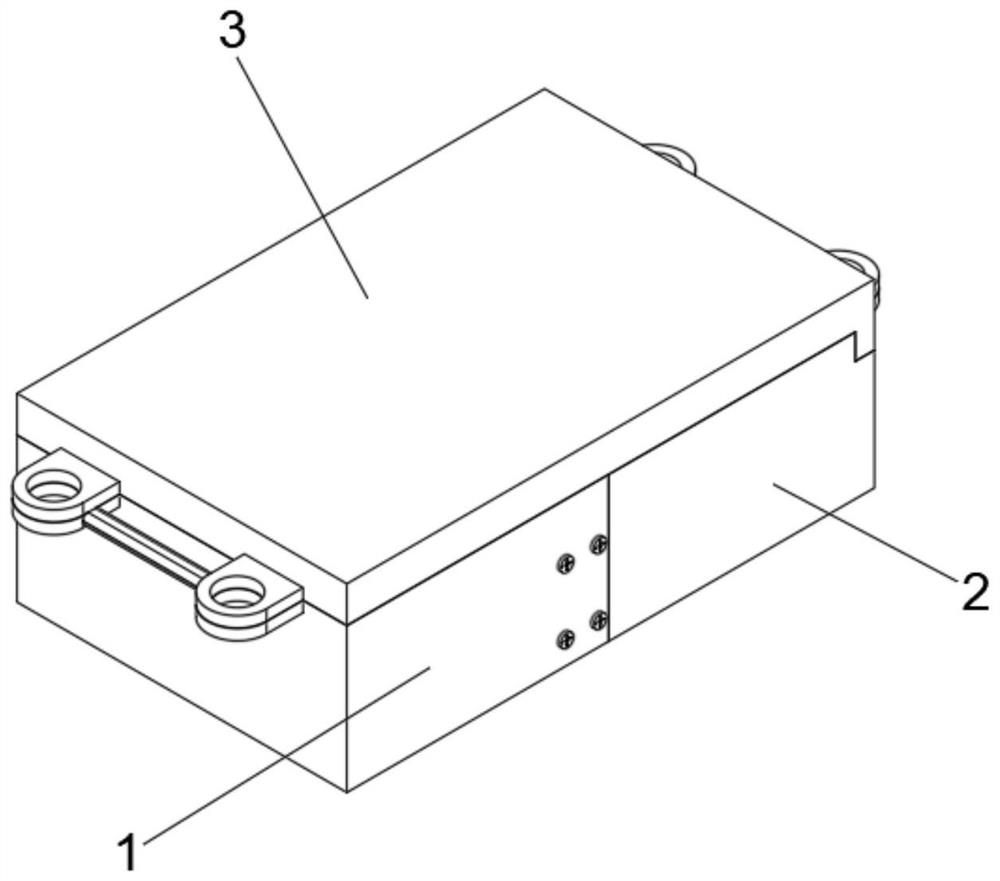

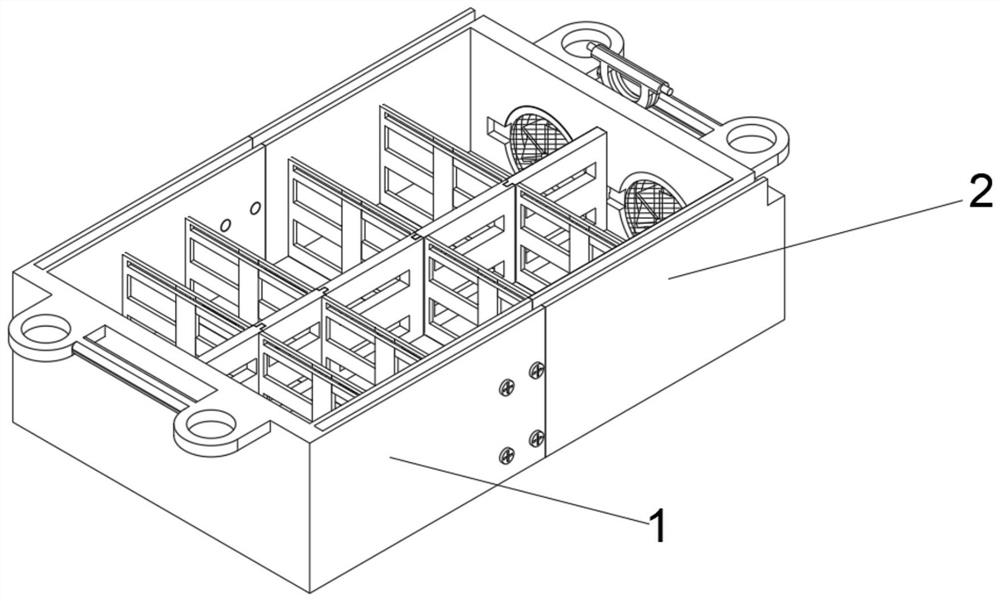

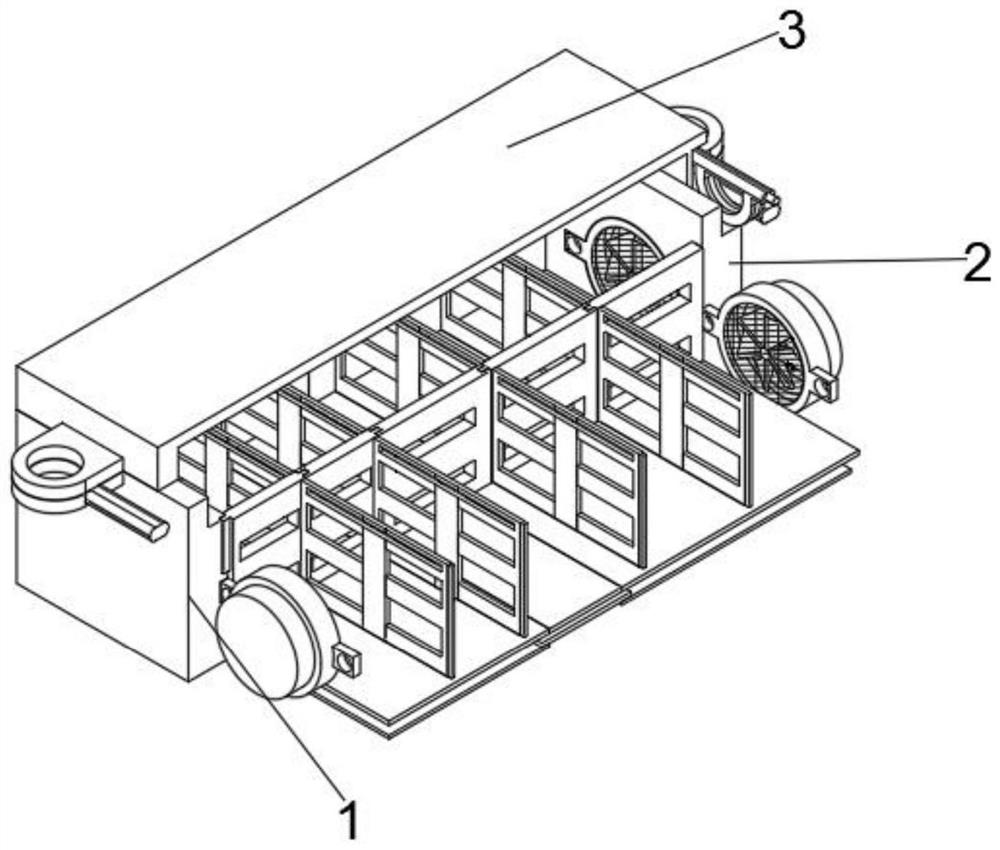

[0056] see Figure 1-Figure 12 As shown, a sliding and detachable battery fixing frame for new energy vehicles is provided, a clamping device 1, a splicing device 2 is symmetrically provided on one side of the clamping device 1, and a top slide is provided on the top of the clamping device 1 and the splicing device 2. connecting device 3;

[0057] The clamping device 1 includes a clamping fixed frame 11, the center line of both sides of one end of the clamped fixed frame 11 is provided with a fixed frame side clamping groove 112 with several screw grooves on the inner wall, and the clamped fixed frame 11 is provided on one side of the inner wall. Cooling devices 14 are arranged symmetrically on both sides of the axis. The cooling device 14 includes a circular motor casing 141. Both sides of the motor casing 141 are provided with connecting ears 142. One side of the connecting ears 142 is fixed to the inner wall of the clamping frame 11 by bolts. A motor 143 is arranged inside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com