Mounting structure of assembly type wall protection plate

A technology for installing structures and wall panels, which is applied in building components, building structures, covering/lining, etc., and can solve problems such as inconvenient maintenance and replacement of wall panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

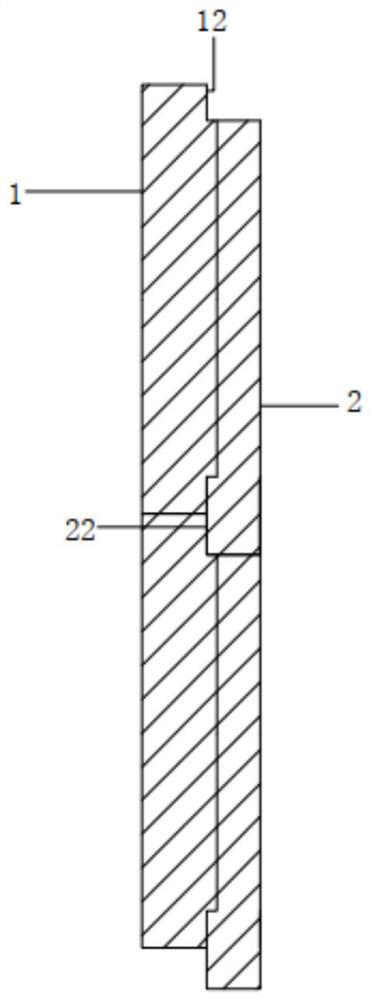

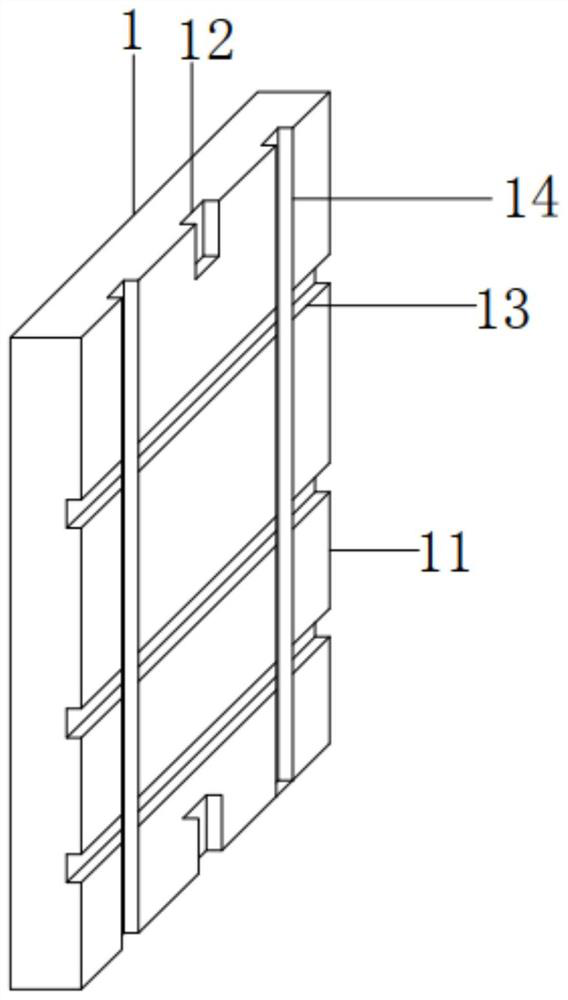

[0039] see Figure 1 to Figure 4 , the figure shows the installation structure of a modular wall panel provided by Embodiment 1 of the present invention, the substrate 1, the substrate 1 is a board structure, and the substrate 1 is provided with a first bonding surface 11, The upper and lower ends of the first bonding surface 11 are respectively provided with connecting grooves 12, and the first bonding surface 11 is provided with a plurality of first positioning grooves 13 and a plurality of second positioning grooves 14;

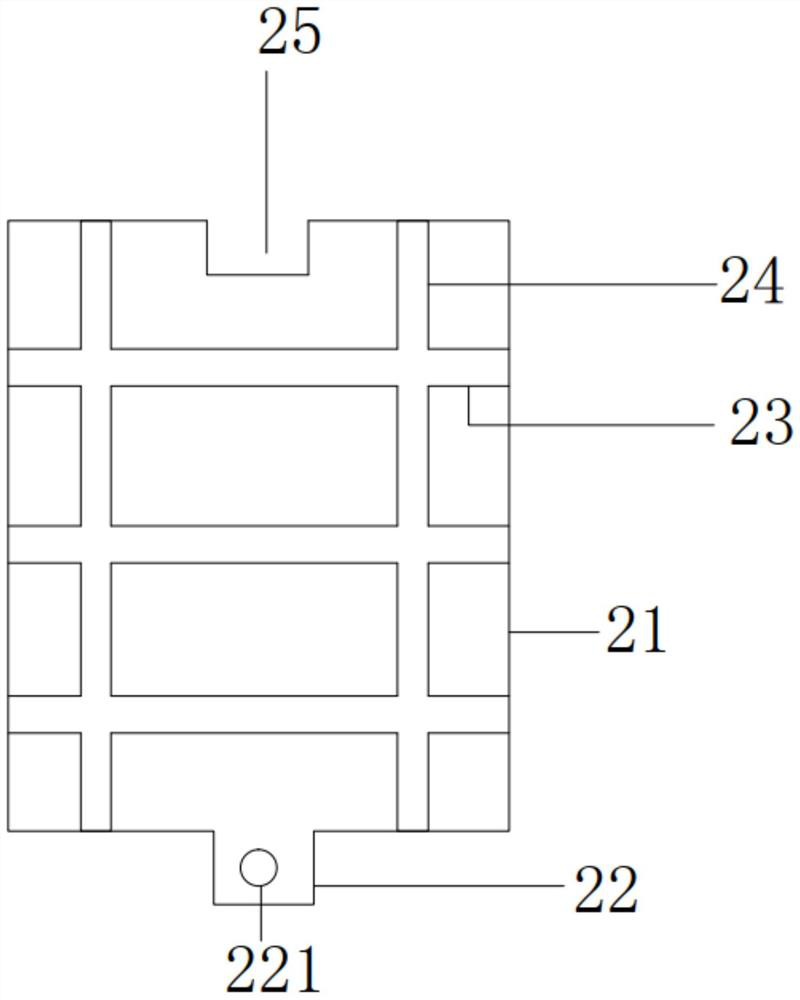

[0040] The backing plate 2, the backing plate 2 is provided with a second bonding surface 21, the second bonding surface 21 is bonded to the first bonding surface 11, and the second bonding surface 21 is provided with Matching the connecting portion 22 of the connecting groove 12, the second fitting surface 21 is provided with a notch 25 at one end opposite to the connecting portion 22, and the second fitting surface 21 is provided with a plurality of firs...

Embodiment 2

[0046] see Figure 1 to Figure 4, the figure shows the installation structure of a modular wall panel provided by the second embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: several One positioning groove 13 is arranged in parallel and equidistant along the short side of the substrate 1 , and several second positioning grooves 14 are arranged in parallel and equidistant along the long side of the substrate 1 ; the first positioning groove 13 is perpendicular to the second positioning groove 14 . Through the improvement of the above structure, the connection between the backing plate and the base plate can be made more stable, and the force can be balanced, so that the overall stability of the wall panel can be improved.

Embodiment 3

[0048] see Figure 1 to Figure 4 , the figure shows the installation structure of a modular wall panel provided by the third embodiment of the present invention. On the basis of the above-mentioned embodiments, this embodiment further makes the following technical solutions as improvements: the connecting part 22 is provided with a through hole 221, and the connecting groove 12 is provided with a protrusion 121, and two adjacent protrusions 121 are sleeved in the through hole; the through hole 221 is a circular through hole, and the protrusion 121 is a semicircular bump. Through the improvement of the above structure, when the backing boards are spliced, the protrusions on the two adjacent backing boards are spliced into circular bumps, and when they are socketed in the through holes, the connection between the adjacent substrates can be made more stable, so that further Improve the overall stability of the clapboard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com