A Quantitative Method for Adding Chemical Reagents to Improve the Dewaterability of Old Sludge

A technology of chemical reagents and quantitative methods, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge treatment, etc., can solve poor dehydration effect, increased economic cost, inaccurate calculation of chemical reagent usage, etc. problem, to achieve the effect of expanding the scope of application, improving efficiency, saving time and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

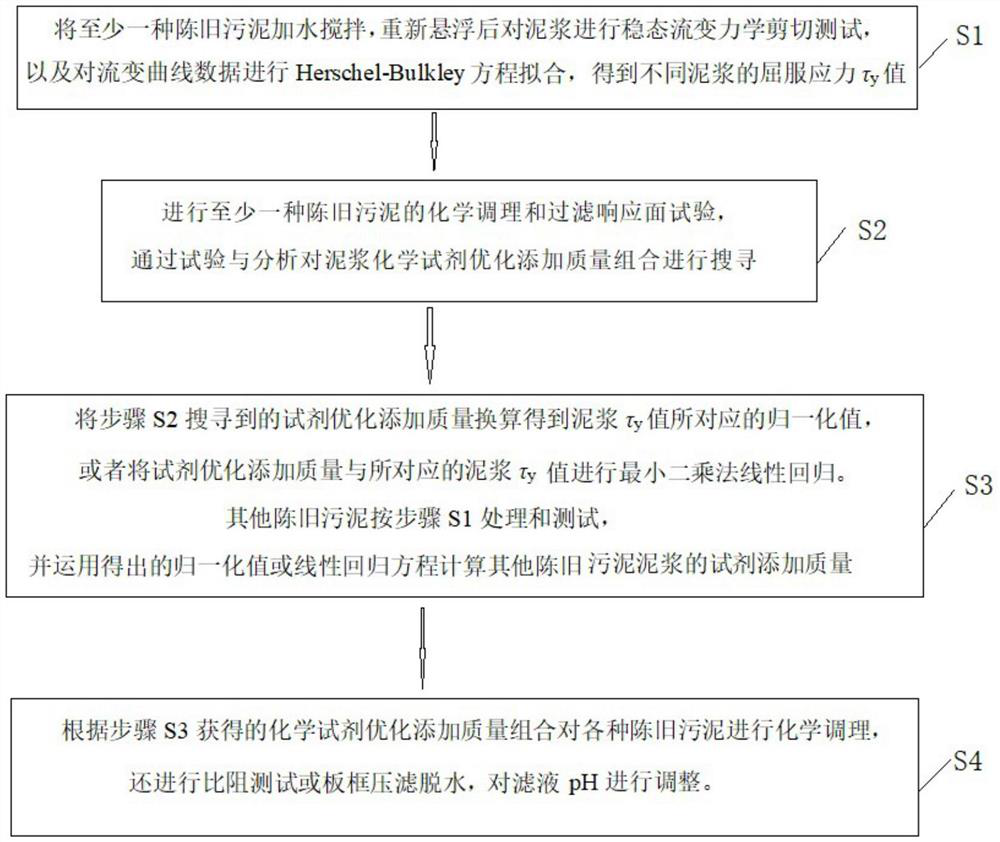

Method used

Image

Examples

Embodiment 1

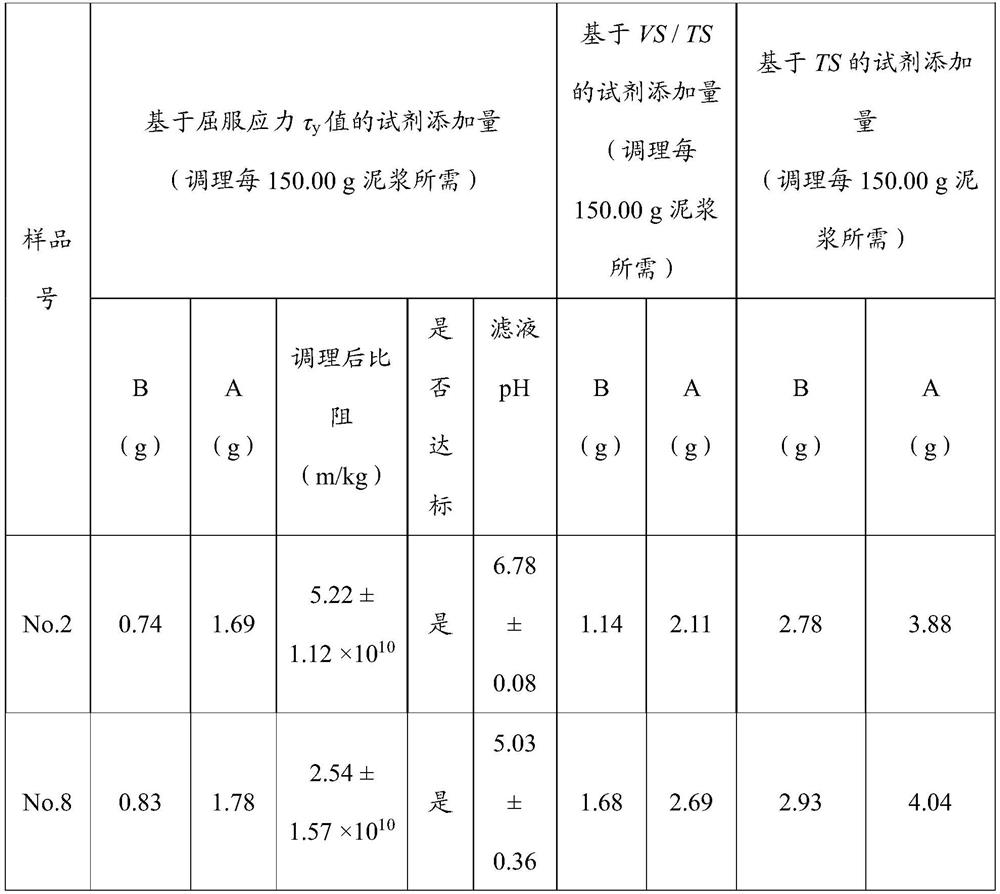

[0046] This example is a quantification method that uses the rheological parameters of old sludge as the benchmark for reagent addition. Under the condition of improving the specific resistance of old mud to the same degree, the content of organic matter and dry basis content alone are used as the benchmark for reagent addition. For comparison, the steps are as follows:

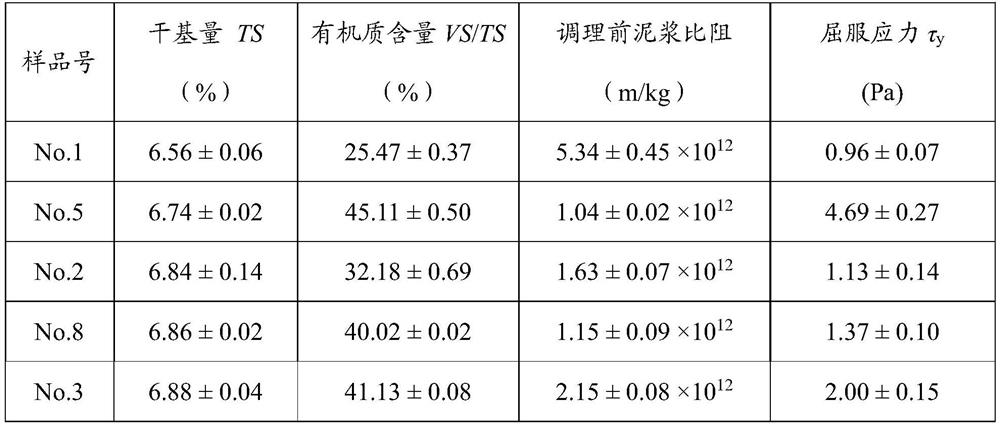

[0047] S1: Select five kinds of old municipal sludge No.1, No.5, No.2, No.8, and No.3 as objects, and the moisture content of the original samples collected are: 75.71±0.58%, 84.53±0.35%, 89.46 ±0.27%, 76.24±0.67%, 83.25±0.35%. The original sludge is stirred with water, and resuspended into a pumpable fluid state whose water content accounts for 93.16±0.14% of the total mass of the mud. Carry out the shear rheological test of the old sludge suspension to obtain the yield stress τ of the suspension y Values, the rheological parameters were tested in triplicate to take the average value; see Table 1.

[0048...

Embodiment 2

[0059] This embodiment is based on the yield stress of the old sludge suspension as the standard quantification method for reagent addition. When dealing with old sludge with different physical and chemical properties, the influence of the previous response surface test procedure on the prediction of reagent dosage is considered. The steps are as follows:

[0060] S1: Select five kinds of old municipal sludge No.1, No.5, No.2, No.8, No.3 as the object, add water to the original sludge and stir, and resuspend so that the water content accounts for the total mass of the sludge is 93.16± 0.14% pumpable flow state slurry. Carry out the shear rheological test of the old sludge suspension to obtain the yield stress τ of the suspension y The rheological parameters were tested in triplicate and averaged. See Table 1.

[0061] S2: Conduct response surface tests on chemical conditioning and filtration of No.1, No.5, No.2, No.8, No.3 old sludge. After setting the chemical conditioning...

Embodiment 3

[0071] This example is a quantification method using the rheological parameters of the old sludge slurry as the benchmark for the amount of reagents added to treat old sludge with similar physical and chemical properties, and to obtain the effect verification of the amount of reagents added to treat old sludge. The steps are as follows:

[0072] S1: Select obsolete municipal sludge A1 and A2 objects, and the water content of collected raw sludge is 83.21±0.38% and 84.57±0.29%, respectively. The original sludge is stirred with water, and resuspended into a pumpable fluid state whose water content accounts for 93.16±0.14% of the total mass of the mud. Carry out the shear rheological test of the old sludge suspension, and take the average value of the test in triplicate to obtain the yield stress τ of the suspension y It is 1.52±0.13Pa and 1.47±0.15Pa.

[0073] S2: Carry out the chemical conditioning filtration and response surface test of A1 old sludge. After setting the chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com