A sampling mechanism for cement clinker grinding equipment

A cement clinker and grinding technology, which is applied in the direction of sampling devices, etc., can solve the problems of working environment hazards, dust leakage, secondary dust flying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

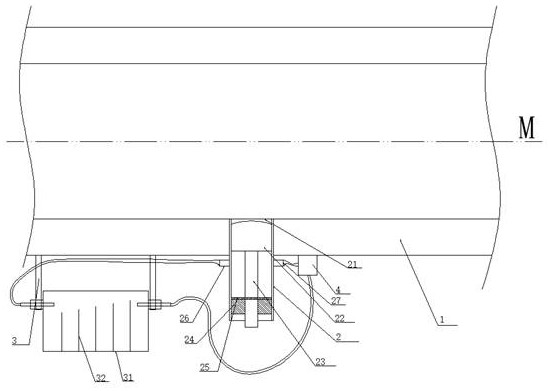

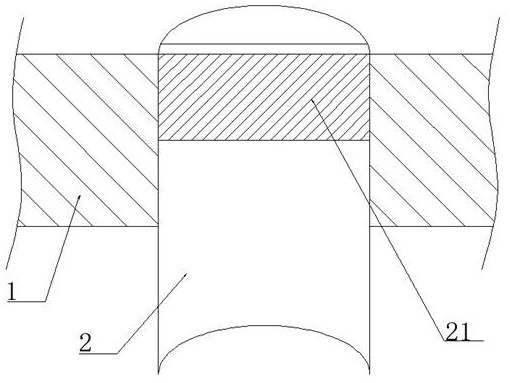

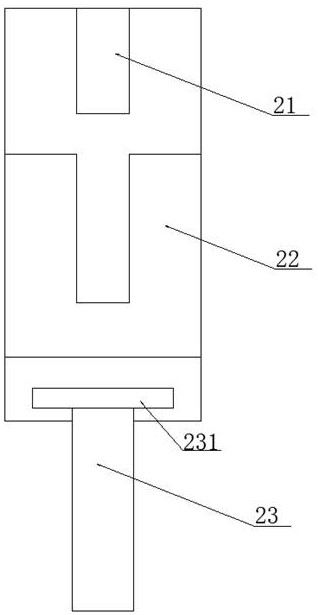

[0018] like figure 1 , figure 2 and image 3 As shown, a sampling mechanism for cement clinker grinding equipment includes cement ground in a rolling and rotating shell 1, and the outer wall of the shell 1 is provided with a sampling cylinder 2 vertically penetrating relative to the shell 1; The port of the sampling cylinder 2 inside the housing 1 is provided with a spacer 21 that separates the port into two separate areas; the sampling cylinder 2 is provided with a U-shaped sealing plug 22 that slides linearly and matches the spacer 21, and the sealing The bottom of the plug 22 is rotatably connected to the fixed rod 23; the fixed rod 23 is screwed to the fixed disk 24; a sealing gasket 25 is arranged between the fixed disk 24 and the fixed rod 23.

[0019] The two sides of the sampling cylinder 2 of the rectilinear motion trajec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com