Automatic lifting type stirring device

A stirring device and automatic lifting technology, which is applied to mixers with rotating stirring devices, mixer accessories, transportation and packaging, etc., can solve the problems of artificial tilting, the inability to accurately control the up and down movement of mixing blades, and the inability to ensure the uniformity of the material bucket Stirring and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

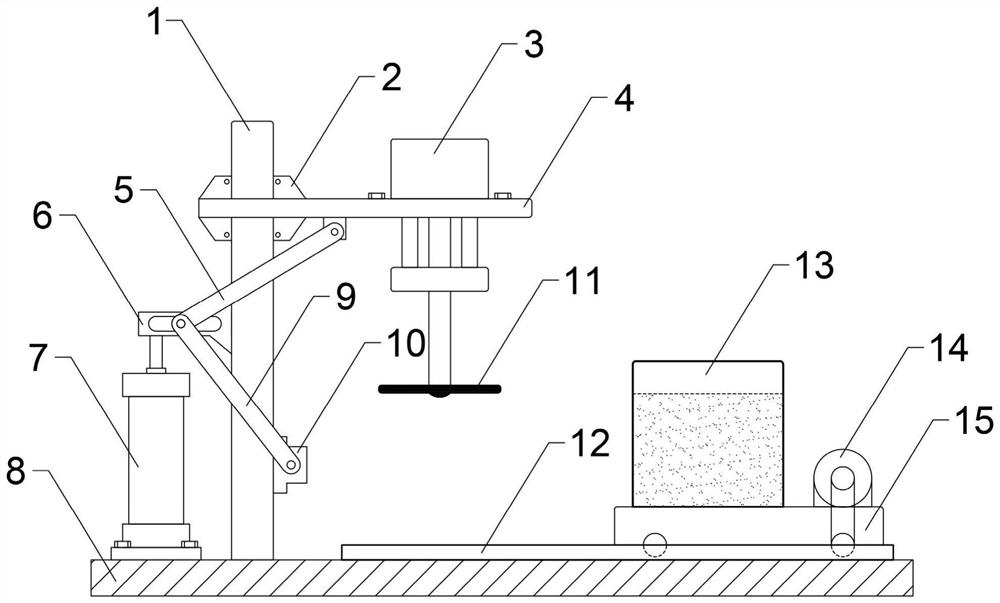

[0013] see figure 1 As shown, a kind of automatic lifting type stirring device comprises bottom plate 8, column 1, mixer 3, lifting plate 4, elevator 7 and first connecting rod 5, second connecting rod 9 and first slider 2, second slider 6, the third slide block 10, the column 1 and the second slide block 6 all have chute, the column 1 and the elevator 7 are installed vertically on the base 8, the first slide block 2, the second slide block 6, The third slider 10 is sequentially arranged in the chute of the column 1 from top to bottom, and the second slider 6 is also fixedly connected with the elevator 7. The lifting plate 4 is horizontally installed on the column 1 through the first slider 2, and the mixer 3 Installed on the front side of the lifting plate 4, one end of the first connecting rod 5 and the second connecting rod 9 are hinged in the chute of the second slider 6, and the other end of the first connecting rod 5 is hinged with the lower end surface of the lifting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com