Pressure limiting valve of pressure cooker

A pressure-limiting valve and pressure cooker technology, applied in the field of pressure-limiting valves for pressure cookers, can solve problems such as food contamination, dropping, and pressure-limiting valves are not easy to clean, and achieve the effects of preventing pollution, preventing contamination, and reducing the flow path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

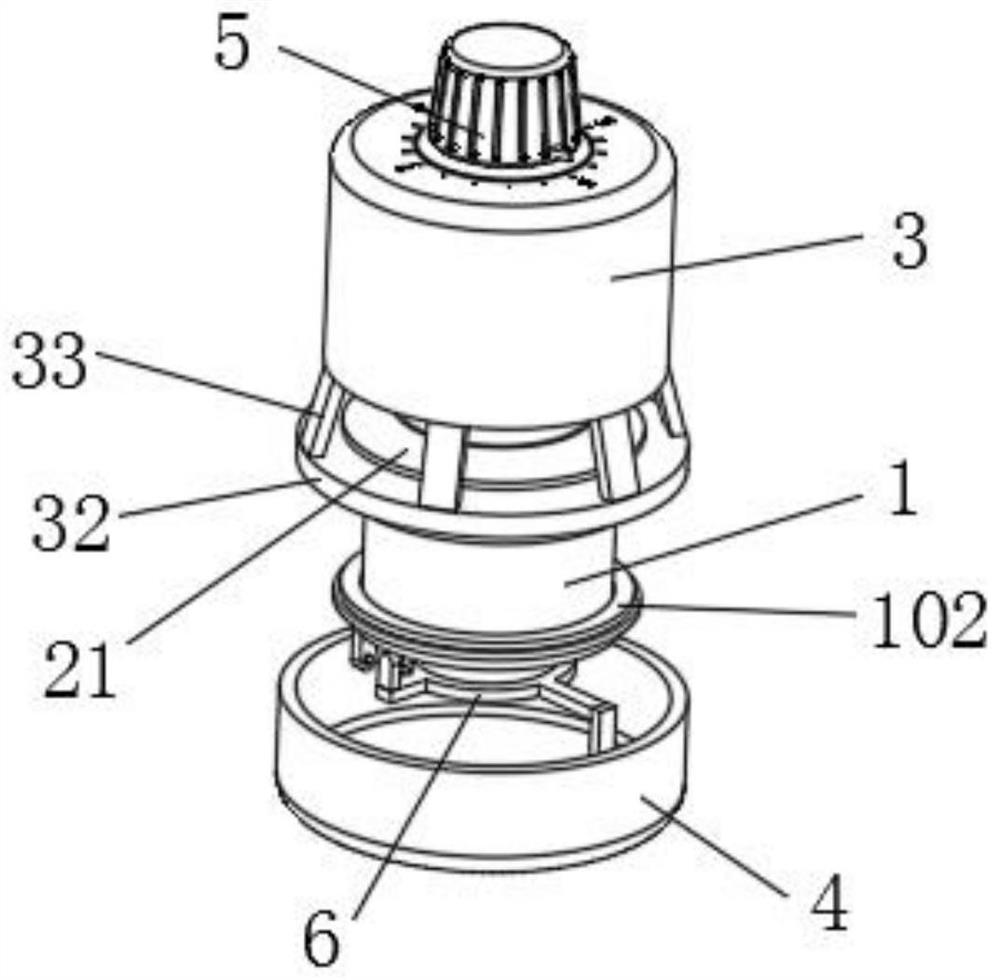

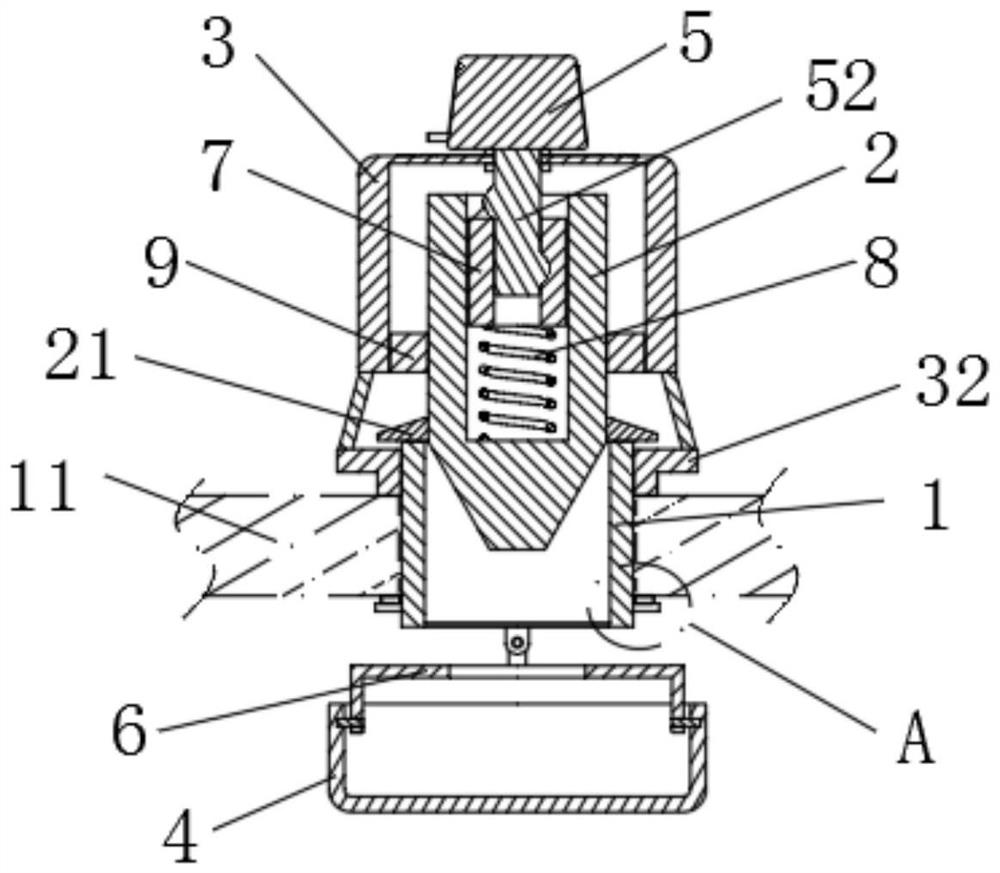

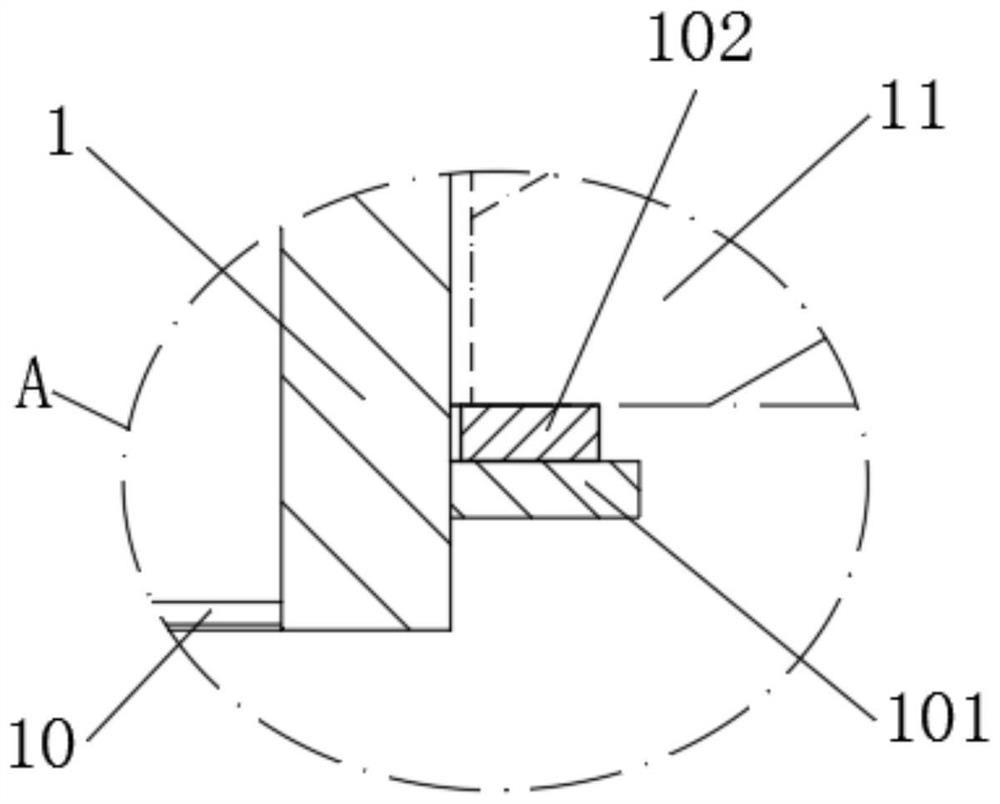

[0042] Example: Reference Figure 1-8 A pressure limiting valve for a pressure cooker as shown includes a base cylinder 1, a limiting flange ring 101 is installed on the outer side wall of the base cylinder 1 near the bottom end, and a receiving box 4 is installed at the bottom end of the base cylinder 1 through a multi-directional rotation mechanism. , the opening of the receiving box 4 corresponds to the bottom end of the base cylinder 1, the outer side wall of the base cylinder 1 is provided with a threaded structure, the threaded structure is screwed and installed with a fixing ring 32, and the top side of the fixing ring 32 is connected by a plurality of connecting rods 33 is installed with an outer cover 3, the inner side wall of the outer cover 3 is slidably installed with a pressure head 2 through a sliding mechanism, the outer side wall of the pressure head 2 is matched with the inner side wall of the base cylinder 1, and the bottom end of the pressure head 2 A flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com