High-strength chiral compression-torsion superstructure material

A chiral structure, high-strength technology, applied in the field of mechanical metamaterials, can solve the problems of poor durability, damage, and complex structure of compression-torsion structures, and achieve the effect of solid and reliable structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Use a 3D printer to print, the material used is TPU95A, and the water-soluble support material used is PVA.

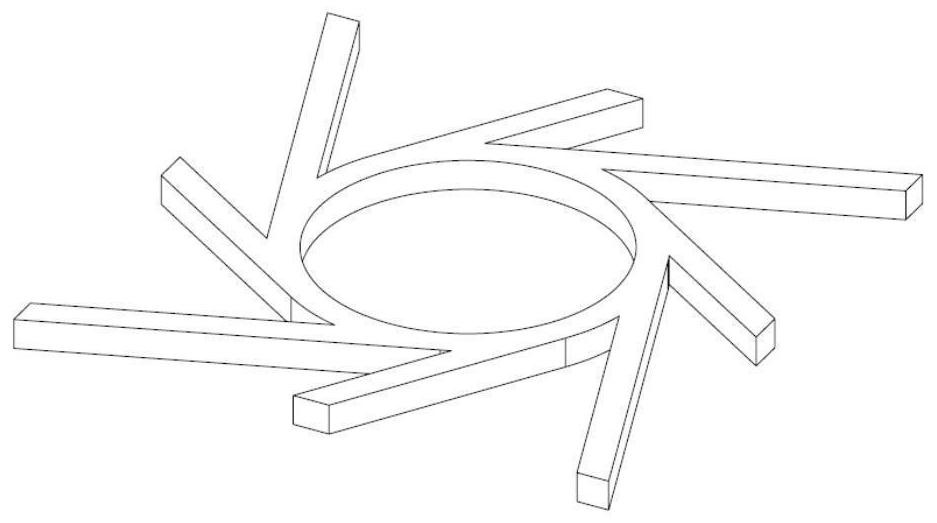

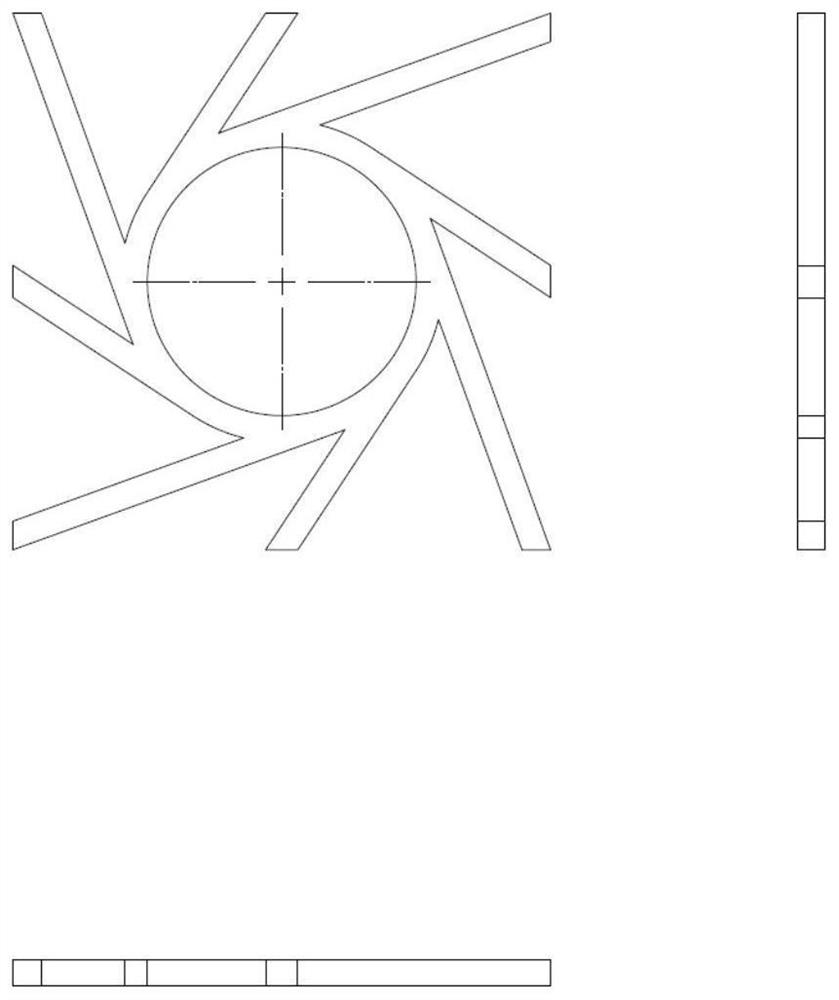

[0031] The in-plane chiral structure of Example 1 is as figure 1 As shown in , its main structure is composed of 8 beams and the central ring, one of the 8 beams is located at the vertices or midpoints of the sides of the square in the plane, and the other end is tangent to the central ring. The beam width is 5mm, the thickness is 5mm, the inner radius of the central ring is 25mm, the outer radius is 30mm, and the thickness is 5mm.

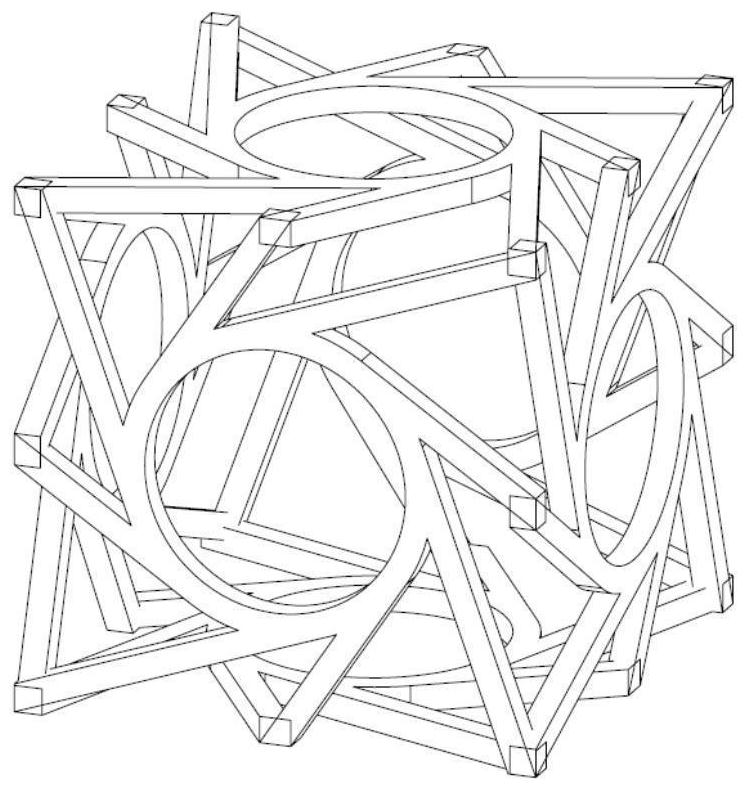

[0032] In embodiment 1, cell such as image 3 As shown, the cell is a cube composed of six in-plane chiral structures perpendicular to each other.

[0033] In Example 1, 1×1×8 is stacked as Figure 7 As shown, this stack is a structure of 8 cells arranged in 1 row, 1 column, and 8 layers.

[0034] After the printing is completed, soak the printed parts in water, and replace the clean water when the water becomes turbid until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com