Building model machining system and method

A technology of architectural models and processing systems, applied in teaching models, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult processing, low processing efficiency, affecting user impressions, etc. The effect of a wide contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

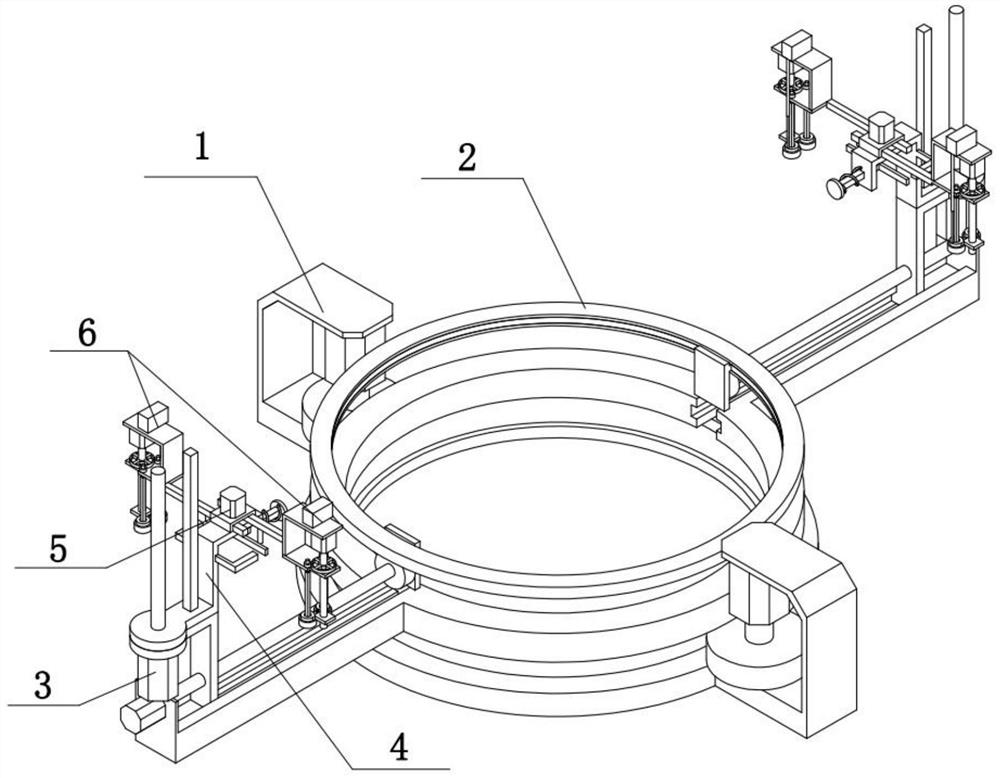

[0033] Combine below Figure 1-8 Describe this embodiment, an architectural model processing system, including a driving assembly 1, a rotating assembly 2, a lifting assembly 3, a clamping assembly 4, an adjusting assembly 5 and a processing assembly 6, the rotating assembly 2 is rotatably connected to the driving assembly 1 , the driving assembly 1 and the rotating assembly 2 are meshed and driven, and there are two lifting assemblies 3, and the two lifting assemblies 3 are respectively slidably connected to the front and rear sides of the rotating assembly 2, and the two lifting assemblies 3 and the rotating assembly 2 are driven by threads. There are two clamping assemblies 4, and the clamping assemblies 4 are slidably connected to the two lifting assemblies 3, and the two lifting assemblies 3 and their corresponding clamping assemblies 4 are driven by threads, and there are two adjusting assemblies 5, The two clamping assemblies 4 are fixedly connected with the adjustment ...

specific Embodiment approach 2

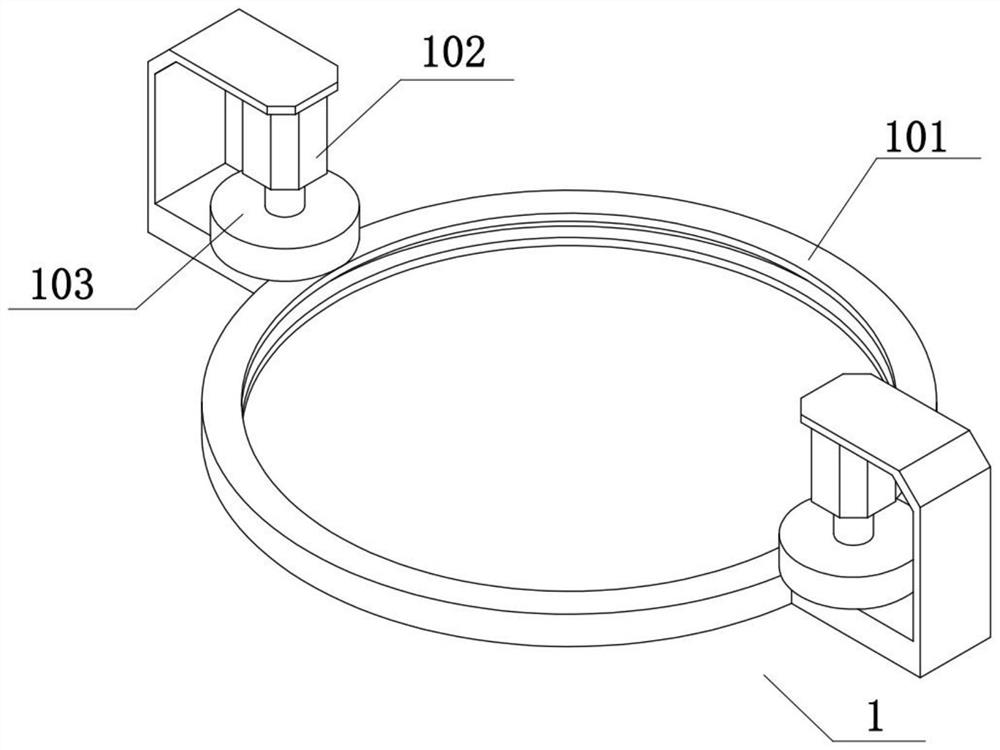

[0036] Combine below Figure 1-8 To illustrate this embodiment, the drive assembly 1 includes a base 101, a rotating motor 102 and a rotating gear 103, two rotating motors 102 are fixedly connected to the base 101, and rotating shafts are fixedly connected to the output shafts of the two rotating motors 102. gear 103.

[0037] Start the two rotating motors 102, the two rotating motors 102 drive the two rotating gears 103 to rotate, and the two rotating gears 103 mesh to drive the rotating assembly 2 to rotate, so as to realize the position adjustment of the two pasting plates.

specific Embodiment approach 3

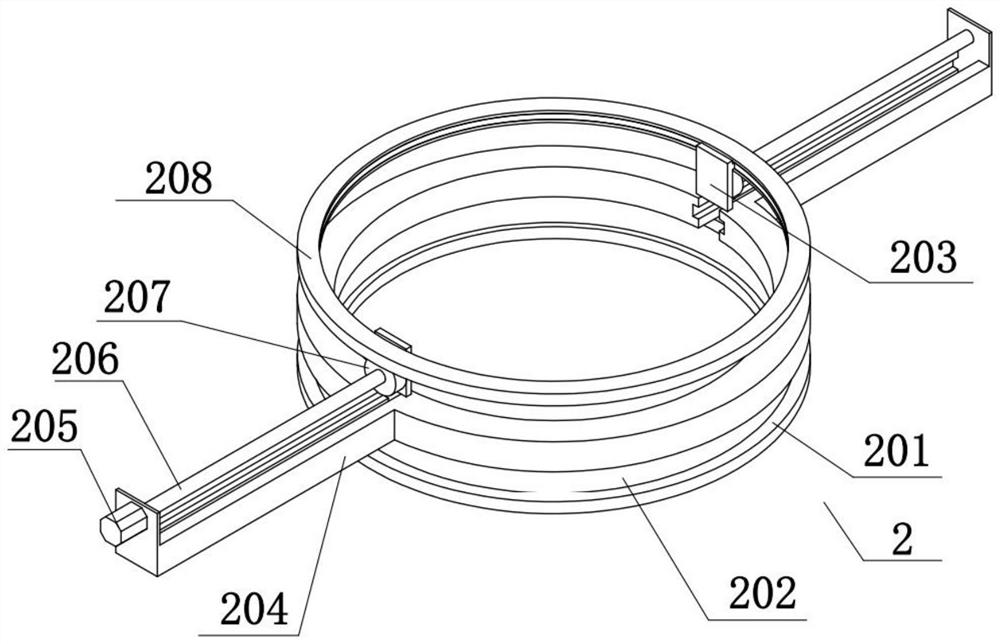

[0039] Combine below Figure 1-8 To illustrate this embodiment, the rotating assembly 2 includes a rotating base 201, a rotating ring gear 202, a rotating fixed seat 203, a sliding base 204, a sliding motor 205, a sliding screw 206, a sliding gear 207 and a synchronous ring gear 208. The seat 201 is rotatably connected to the base 101, the rotating base 201 is fixedly connected with a rotating ring gear 202, the rotating ring gear 202 and the two rotating gears 103 are meshing transmission, and the rotating base 201 is fixedly connected with a rotating fixed seat 203 , two sliding screw rods 206 are rotatably connected on the rotating fixed base 203, the front and rear ends of the rotating base 201 are fixedly connected with sliding bases 204, and one of the sliding bases 204 is fixedly connected with a sliding motor 205, and the sliding motor 205 The output shaft is fixedly connected to one of the sliding screw rods 206, and the sliding gears 207 are fixedly connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com