Internal mixer device for rubber processing

An internal mixer and rubber technology, applied in the field of rubber internal mixer, can solve problems such as increased cost and slow adjustment speed, and achieve the effects of improving lifting efficiency, facilitating movement and positioning, and moving conveniently and quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

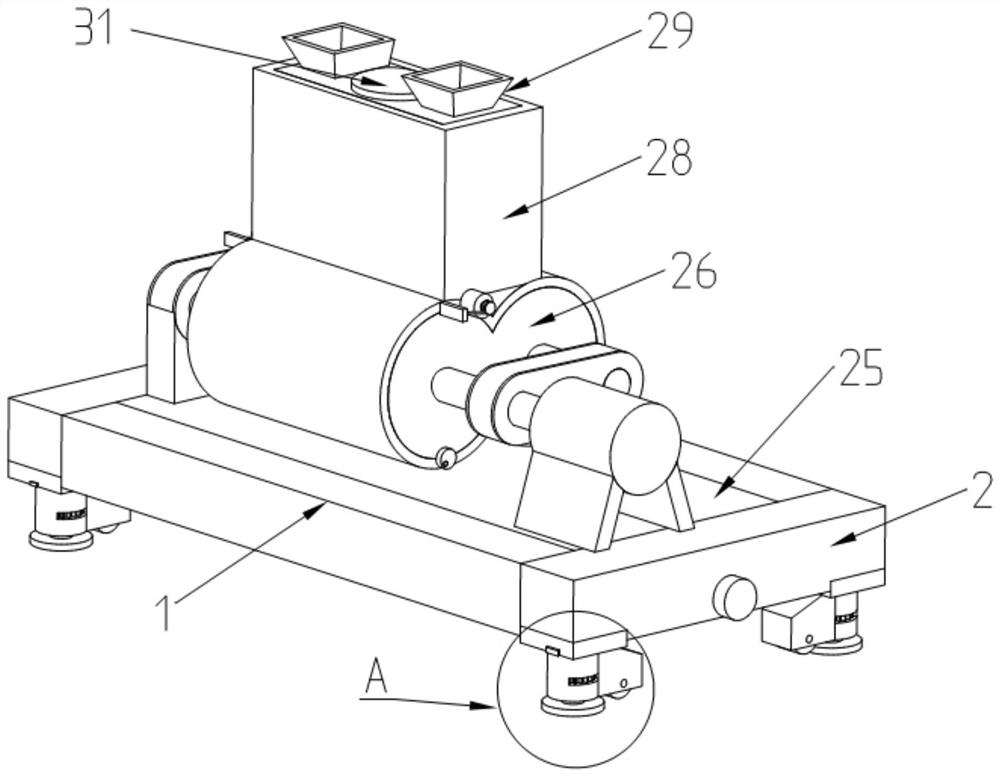

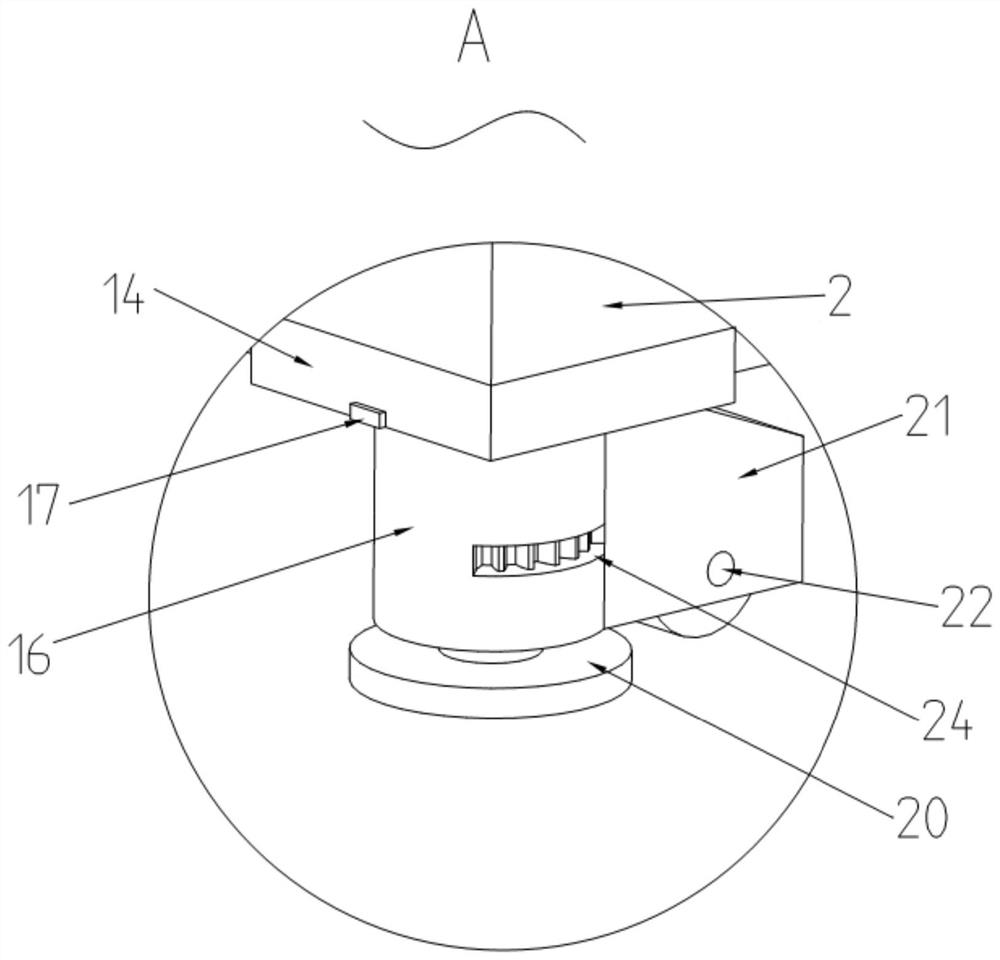

[0031] Such as Figure 1-8As shown, the present invention provides a kind of internal mixer device used in rubber processing, comprising a longitudinal beam 1, the side end of the longitudinal beam 1 is provided with a crossbeam 2, and the middle part of the longitudinal beam 1 and the crossbeam 2 is provided with a fixed plate 25, and the fixed plate 25 is The internal mixer provides a support platform, one end of the crossbeam 2 is provided with a motor 7, and the output end of the motor 7 is provided with a main shaft 3, and the main shaft 3 is respectively provided with a first stop ring 4 and a second stop ring 6 on the outer surface of the cross beam 2, There is a second bearing inside the first limit ring 4 and the second limit ring 6, and the main shaft 3 is well supported and protected by the second bearing inside the first limit ring 4 and the second limit ring 6 , to avoid damage to its long-term use, and the main shaft 3 passes through the beam 2 and the surroundin...

no. 2 example

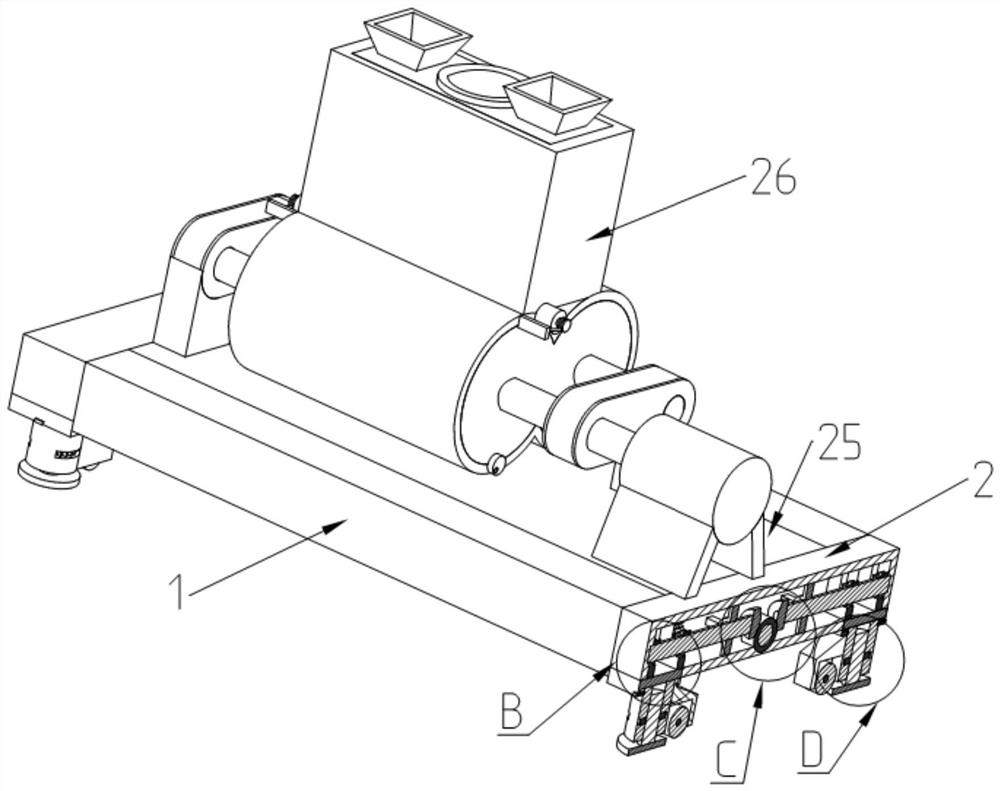

[0036] Based on the internal mixer device used for rubber processing provided in the first embodiment, if the ground is uneven during the actual installation process, the fixed plate 25 is already in an inclined state after the internal mixer device is placed on the ground, so if only If synchronous coarse adjustment and fine adjustment are performed on the bottom leg of the fixed plate 25, the internal mixer on the top of the fixed plate 25 is still in a tilted state. If the tilted state cannot be adjusted in time and accurately, the rubber processing efficiency of the internal mixer will be greatly improved. lower, to solve this problem, combine the Figure 9 , the internal mixer device used in rubber processing also includes: a mixing chamber 26 is arranged on the top of the fixed plate 25, a rotor is arranged inside the mixing chamber 26, a lower top bolt is arranged on the bottom of the mixing chamber 26, and the lower top bolt The bottom of the mixing chamber 26 is provi...

no. 3 example

[0039]Based on the internal mixer device used in rubber processing provided by the second embodiment, in actual use, since the top of the mixing chamber 26 is sealed by the top bolt 33, the internal mixer itself is too heavy, and long-term use will cause ground If the ground breaks and the device is still in working condition, it will not only cause damage to the internal components, but also cause the internal mixer to collapse and cause a major safety accident. Therefore, in order to solve this problem, this kind of rubber processing used The pressure sensor of the internal mixer device can be arranged at the bottom of the top bolt slideway 30 during actual use. When the top bolt 33 was positioned at the bottom of the top bolt slideway 30 and blocked the top of the mixing chamber 26, the pressure sensor's Numerical value will change, and the numerical value change of a plurality of pressure sensors is the same, the pressure value of pressure sensor to pressure sensor is the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com