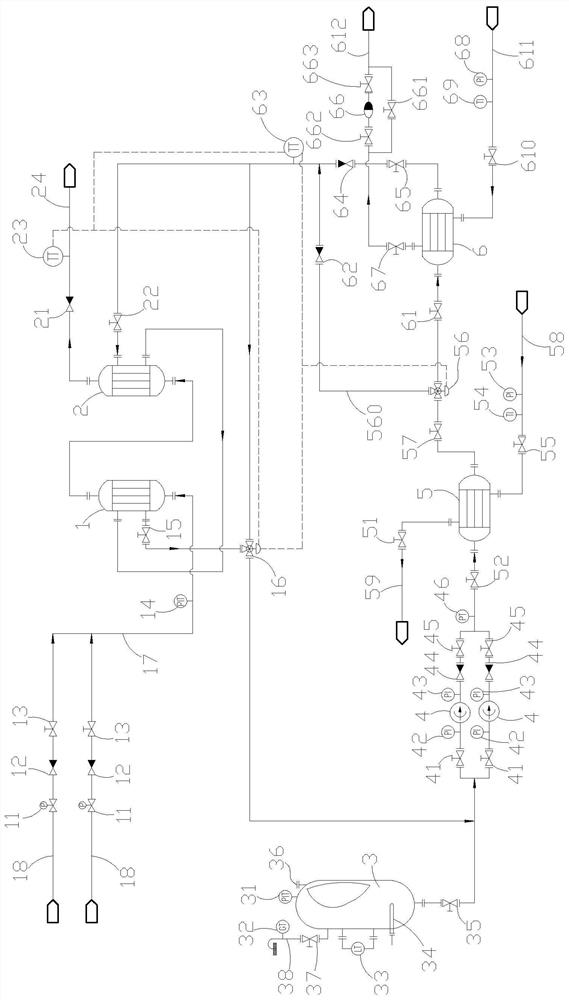

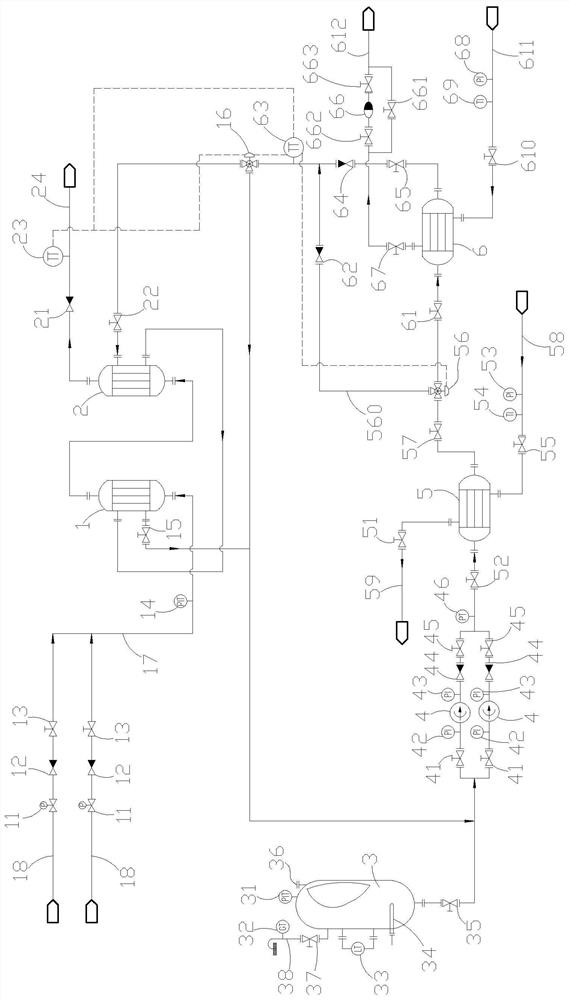

Dual-fuel engine LNG supply system and LNG ship

A dual-fuel engine and air supply system technology, applied in combustion engines, internal combustion piston engines, charging systems, etc., can solve the problems of pipeline rupture, single type of heat source, limited adjustment ability, etc. Good economic performance and the effect of improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0032] The terms "first", "second", "third", "fourth", etc. (if any) in the description and claims of the present invention are used to distinguish similar objects and not necessarily to describe specific sequence or sequence.

[0033] The up, down, left, right, front, back, top, bottom, etc. (if any) orientation words involved in the specification and claims of the present invention refer to the positions in the drawings of the structures in the drawings and the relationship between the structures. It is only defined for the clarity and convenience of expressing the technical solution. It should be understood that the use of location words should not limit the scope of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com