A kind of phthalonitrile resin prepolymer and preparation method thereof

A technology of phthalonitrile resin and phthalonitrile, applied in the field of preparation of phthalonitrile resin prepolymer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Prepolymerization of phthalonitrile resin:

[0025] In the four-necked flask, add 10g (22.83mmol) of biphenyl-type phthalonitrile resin monomer, 2g (9.79mmol) of 1,7-bishydroxymethyl-m-carborane, and then add 20g of N-methylpyrrolidone , heated to 180 ° C, mechanically stirred for 4 hours, after the reaction was completed, the solution was poured into deionized water, stirred for 30 minutes, and filtered under reduced pressure to obtain the precipitated precipitate. The precipitate was dried in an oven at 100 °C for 20 h to obtain a biphenyl-type phthalonitrile resin prepolymer. The prepolymer has good properties in ethyl acetate, acetone, tetrahydrofuran, 1,4-dioxane, N,N-dimethylformamide, N,N-dimethylacetamide and N-methylpyrrolidone. good solubility.

[0026] Prepolymer curing:

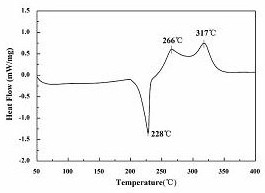

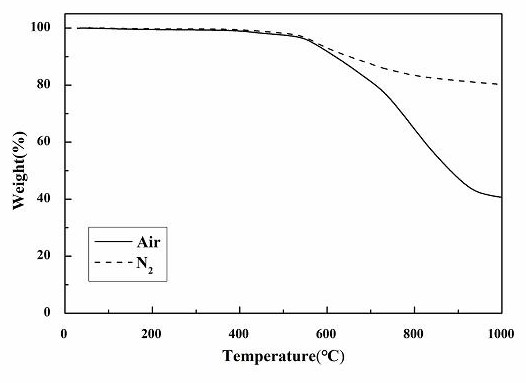

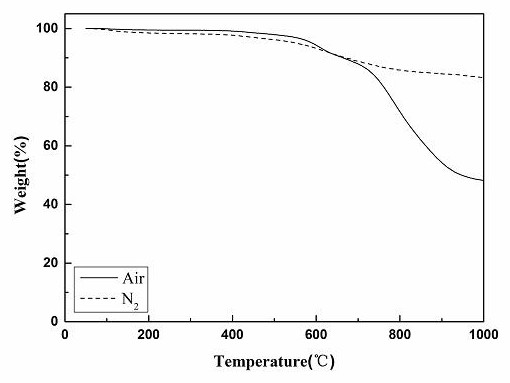

[0027] Weigh the synthesized biphenyl phthalonitrile resin prepolymer in a ceramic crucible, and solidify it in a muffle furnace according to the following step heating program (heating ...

Embodiment 2

[0031] Prepolymerization of phthalonitrile resin:

[0032] In the four-necked flask, add 15g (31.25mmol) of bisphenol A type phthalonitrile resin monomer, 1.5g (7.34mmol) of 1,7-bishydroxymethyl-m-carborane, then add 25g of N,N - Dimethylformamide, heated to 150°C, mechanically stirred for 2 hours, poured the solution into deionized water after the reaction, stirred for 60 minutes, and filtered under reduced pressure to obtain the precipitated precipitate. The precipitate was dried in an oven at 100 °C for 20 h to obtain a biphenyl-type phthalonitrile resin prepolymer. The prepolymer has good properties in ethyl acetate, acetone, tetrahydrofuran, 1,4-dioxane, N,N-dimethylformamide, N,N-dimethylacetamide and N-methylpyrrolidone. good solubility.

[0033] Prepolymer curing:

[0034] Weigh the synthesized bisphenol A phthalonitrile resin prepolymer in a ceramic crucible, and solidify it in a muffle furnace according to the following step heating program (the heating rate is 5 ...

Embodiment 3

[0037] Prepolymerization of phthalonitrile resin:

[0038] In the four-necked flask, add 30g (68.49mmol) of biphenyl-type phthalonitrile resin monomer, 8g (39.16mmol) of 1,7-bishydroxymethyl-m-carborane, then add 40g of N,N-dicarbonyl Methylacetamide was heated to 165°C and mechanically stirred for 6 hours. After the reaction, the solution was poured into deionized water, stirred for 10 minutes, and filtered under reduced pressure to obtain the precipitated precipitate. The precipitate was dried in an oven at 100 °C for 5 h to obtain a biphenyl-type phthalonitrile resin prepolymer. The prepolymer has excellent properties in ethyl acetate, acetone, tetrahydrofuran, 1,4-dioxane, N,N-dimethylformamide, N,N-dimethylacetamide and N-methylpyrrolidone. good solubility.

[0039] Prepolymer curing:

[0040] Weigh the synthesized biphenyl phthalonitrile resin prepolymer in a ceramic crucible, and solidify it in a muffle furnace according to the following step heating program (the heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com