Material used for 3D printing and preparation method thereof

A technology of 3D printing and modified materials, which is applied in the field of 3D printing, can solve the problems that fused deposition modeling technology cannot be used, the adaptability of 3D printing materials is not high, and the heating temperature is not easy to control. The effect of molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0044] In the first embodiment, the material preparation method for 3D printing bone tissue mainly includes the following steps:

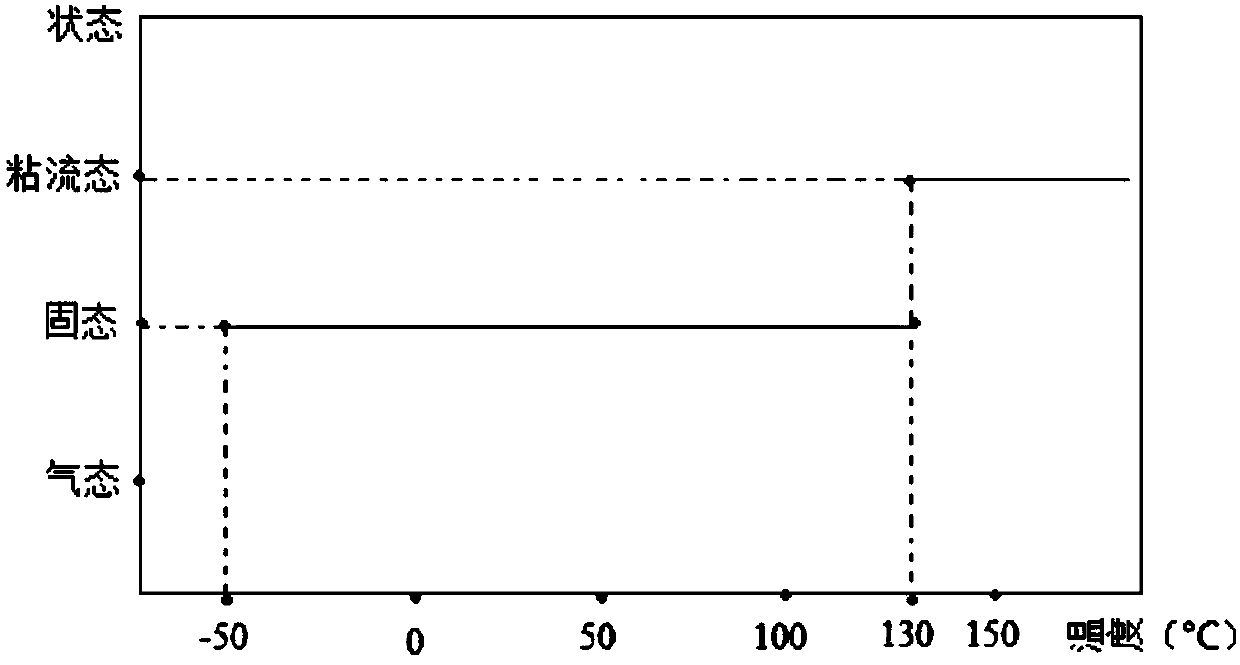

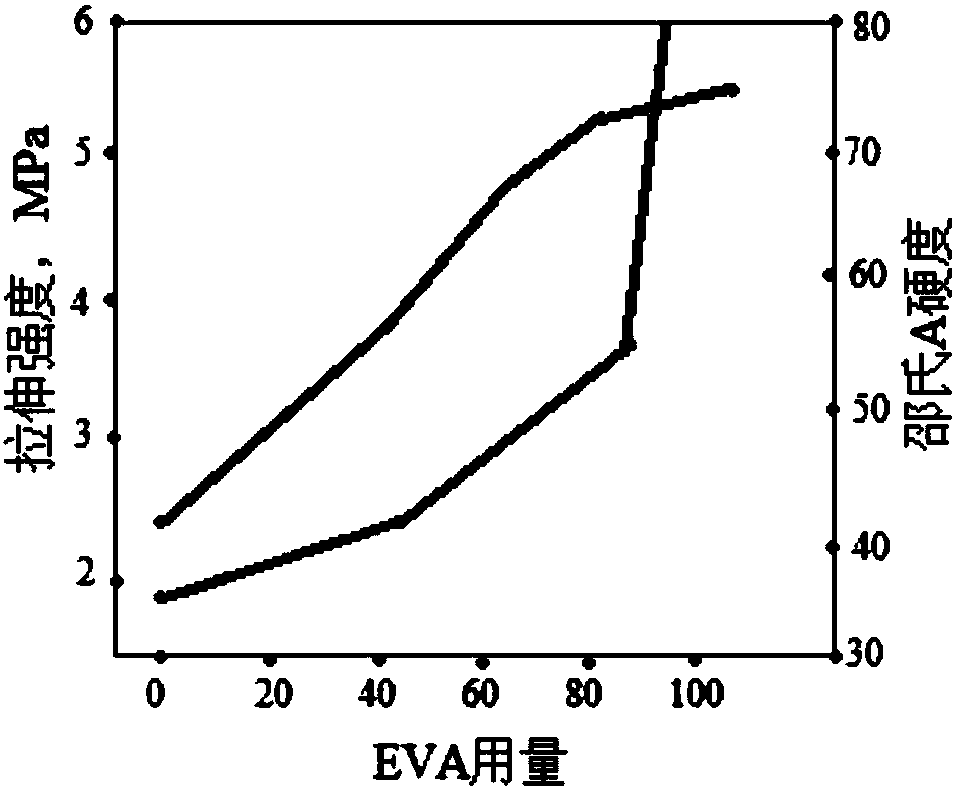

[0045] S1: The weight percentages are 90%~96.5% ethylene-vinyl acetate copolymer, 1%~3% emulsion polystyrene butadiene rubber, 1%~3% solution polystyrene butadiene rubber, 2%~6% auxiliary modification The mixture of materials is added to a high-speed mixer with a melting temperature of 130°C, preferably 160°C, and mixed for 3-6 hours. The ethylene-vinyl acetate copolymer (EVA) is preferably 92%, and the emulsion polystyrene butadiene rubber is preferably 1.93%. The styrene-butadiene rubber is preferably 1.93%; the percentage by weight of each component of the auxiliary modified material is: crosslinking agent 5%-22%, compounding agent 38%-57%, antioxidant 8%-17%, Toughening agent 4%-7%, anti-hydrolysis agent 8%-17%, melt fusion enhancer 5%-20%;

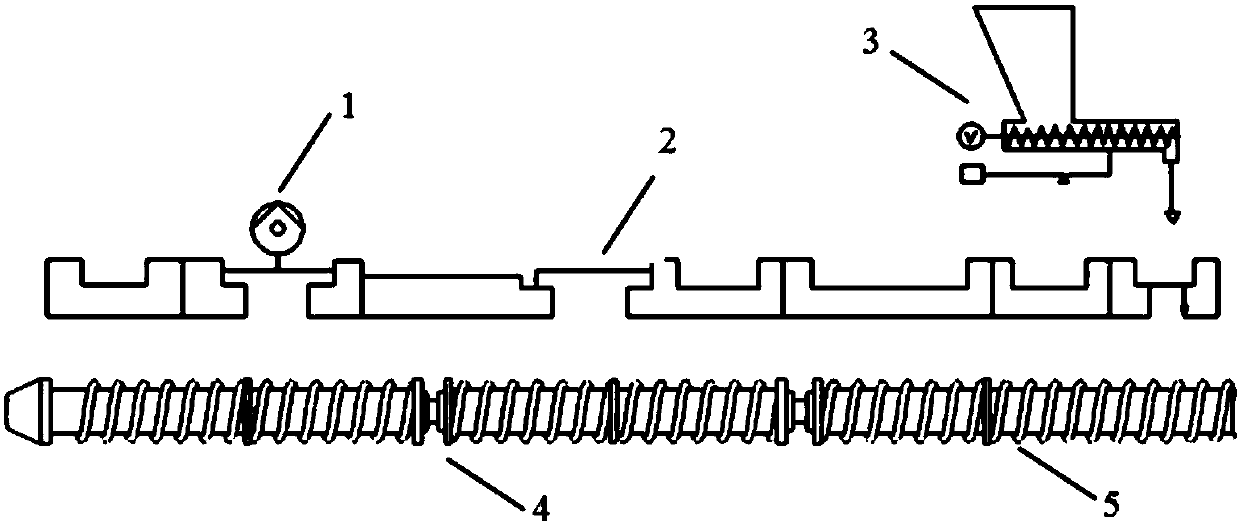

[0046] S2: Put the mixed material prepared in step S1 into a screw extruder for melting and heat refin...

no. 2 example

[0051] In the second embodiment, the material preparation method for 3D printing bone tissue mainly includes the following steps:

[0052] S1: The weight percentages are 60%~91% ethylene-vinyl acetate copolymer, 3%~6% emulsion polystyrene butadiene rubber, 3%~6% solution polystyrene butadiene rubber, 2%~6% auxiliary modification The mixture of materials is added to a high-speed mixer with a melting temperature of 140°C, preferably 160°C, and mixed thoroughly for 2-4 hours. The ethylene-vinyl acetate copolymer (EVA) is preferably 80%, and the emulsion polystyrene butadiene rubber is preferably 4.5%. The styrene-butadiene rubber is preferably 4.5%; the percentage by weight of each component of the auxiliary modified material is: crosslinking agent 5%-22%, compounding agent 38%-57%, antioxidant 8%-17%, Toughening agent 4%-7%, anti-hydrolysis agent 8%-17%, melt fusion enhancer 5%-20%;

[0053] S2: Put the mixed material prepared in step S1 into a screw extruder for melting and he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com