Integrated lost foam casting mold

A lost foam and integrated technology, applied in the direction of casting molding equipment, etc., can solve the problems such as the inability to arrange the automatic core-pulling of the inner cavity of the lower mold, affect the demoulding, and the drive mechanism cannot use the induction device, so as to improve the efficiency of fully automated production , The effect of convenient drainage production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in detail in conjunction with accompanying drawing and specific embodiment:

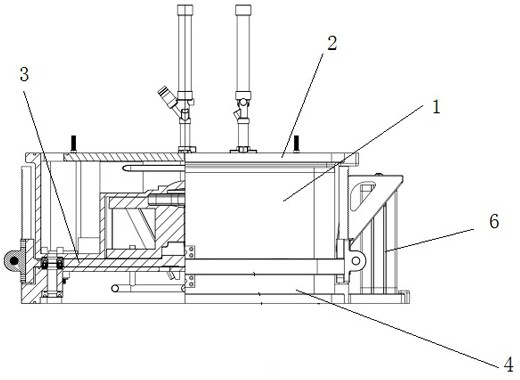

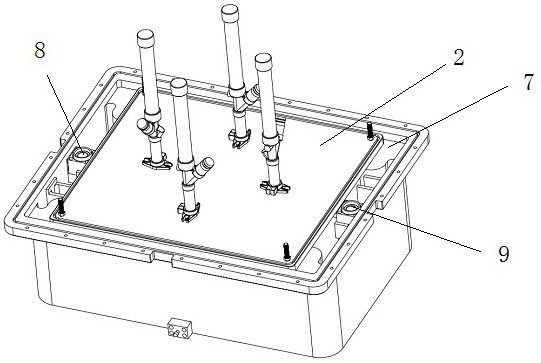

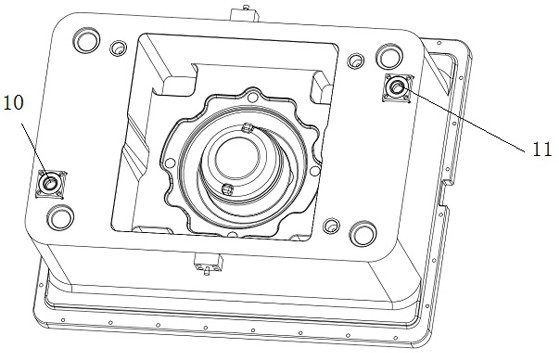

[0017] Such as figure 1 , Figure 6 As shown, an integrated lost foam mold, the integrated lost foam mold has an upper mold and a lower mold; combined figure 2 , image 3 , the upper mold is provided with an upper mold air chamber 1 and an upper mold insert; the upper mold air chamber 1 is a hollow structure with an upper end surface opening; the upper mold insert is a molded product with a hollow structure. The cavity assembly, together with the upper mold air chamber 1, forms a mold cavity with an upper end face opening, and the top opening of the upper mold air chamber 1 is provided with a material gun plate 2; combined Figure 4 , Figure 5 , the lower mold is provided with a lower mold air chamber 4 and a lower mold insert corresponding to the upper mold air chamber; the top of the lower mold air chamber 1 is provided with an external stripper plate...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap