Automatic loading and unloading and storage method of piston ring electroplating production line

A technology of automatic loading and unloading and electroplating production line, which is applied in the direction of electrolytic components, electrolytic process, etc., to achieve the effect of improving efficiency, high stability, and guaranteed position control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is described in detail below in conjunction with accompanying drawing:

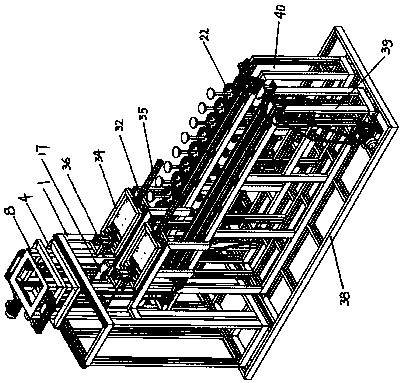

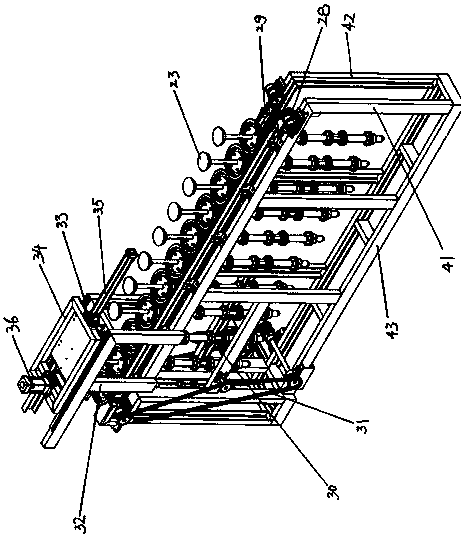

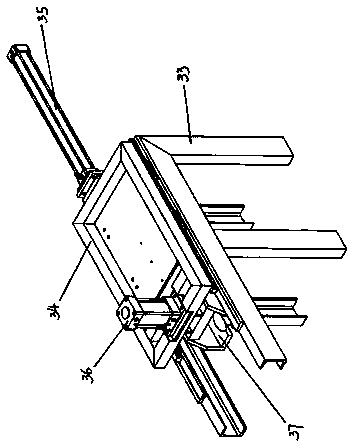

[0037] An automatic loading and unloading and storage mechanism for a piston ring electroplating production line, including a storage base 38, on which a feeding transmission and storage rack 39 and a loading transmission and storage rack are arranged parallel to each other along the left and right horizontal directions 40. A column-type box frame 1 is arranged on the left side of the unloading transmission and storage rack 39 and the loading transmission and storage rack 40, and a piston ring electroplating workpiece is installed in the air directly above the rear of the column-type box frame 1. The hook, the structure of the blanking transmission and the storage rack 39 are the same as the structure of the feeding transmission and the storage rack 40. The feeding transmission and the storage rack 40 are composed of a rectangular frame base 43, a front rectangular vertical fra...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap