A Method for Controlling Creep Anisotropy of Cold-rolled Pre-deformed Alloy

An anisotropic and pre-deformation technology, applied in the field of aluminum alloy processing, can solve problems such as increasing the difficulty of springback prediction and compensation, achieve high-efficiency and high-precision forming manufacturing, reduce creep aging anisotropy, and operate The effect of the simple method

Active Publication Date: 2022-06-03

CENT SOUTH UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

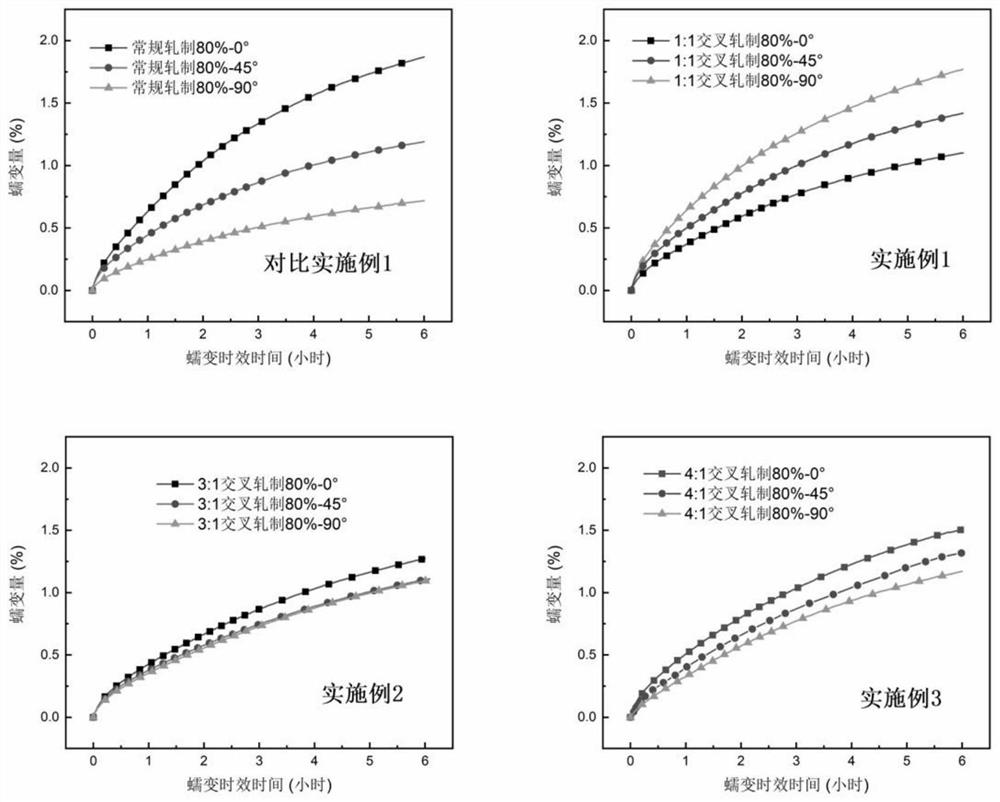

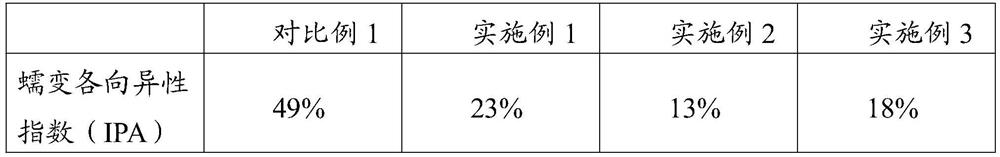

In the process of creep aging deformation, creep deformation and precipitation strengthening occur at the same time. Due to the heterogeneity of the internal microstructure of the material, the anisotropy of creep strain and mechanical properties of the component will occur after creep aging deformation, increasing The difficulty of predicting and compensating springback after creep aging forming of components makes it a challenge to realize high-efficiency and high-precision forming and manufacturing of aluminum alloys with large deformation shapes

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

[0034]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention provides a method for regulating and controlling the creep anisotropy of cold-rolled pre-deformed alloys. The method adopts non-equal cross-rolling to carry out two cold-rolls on the aluminum alloy plate, and through the The creep anisotropy is controlled by the ratio of deformation amount, which specifically includes: solid solution of the aluminum alloy sheet; water quenching of the aluminum alloy sheet after solid solution; two cold rolling of the water quenched aluminum alloy sheet, and then Perform creep age forming. The present invention adopts the method of non-equal cross rolling and can greatly reduce the creep aging anisotropy of the aluminum alloy material under the premise of maintaining a relatively high creep aging deformation efficiency of the aluminum alloy material. The operation method is simple and suitable for actual production applications. High-efficiency and high-precision forming and manufacturing of aluminum alloy components can be realized.

Description

A method for regulating the creep anisotropy of cold-rolled pre-deformed alloys technical field The present invention relates to the field of aluminum alloy processing, particularly a kind of control cold-rolled pre-deformed alloy creep anisotropy. method. Background technique Aluminum and aluminum alloys have the advantages of low density, high corrosion resistance, good electrical and thermal conductivity, and are widely used in aerospace. and rail transit. In order to meet the development needs of large-scale transportation equipment such as modern aerospace / high-speed rail, The components used in the next service put forward higher quality manufacturing requirements to achieve high performance, high precision and high performance of complex shape components. Integral structure manufacturing has become one of the key manufacturing technologies in the modern manufacturing field. Creep aging forming is to make the material in a certain An advanced forming techno...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22F1/04C21D1/18C21D8/02

CPCC22F1/04C22F1/002C21D1/18C21D8/0236C21D8/0247

Inventor 刘春辉陈龙辉杨建使马培培湛利华

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com