Method for regulating and controlling creep anisotropy of cold-rolled pre-deformed alloy

An anisotropic and pre-deformation technology, applied in the field of aluminum alloy processing, can solve problems such as increasing the difficulty of springback prediction and compensation, and achieve high-efficiency and high-precision forming manufacturing, simple operation methods, and reduced creep aging. Anisotropic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

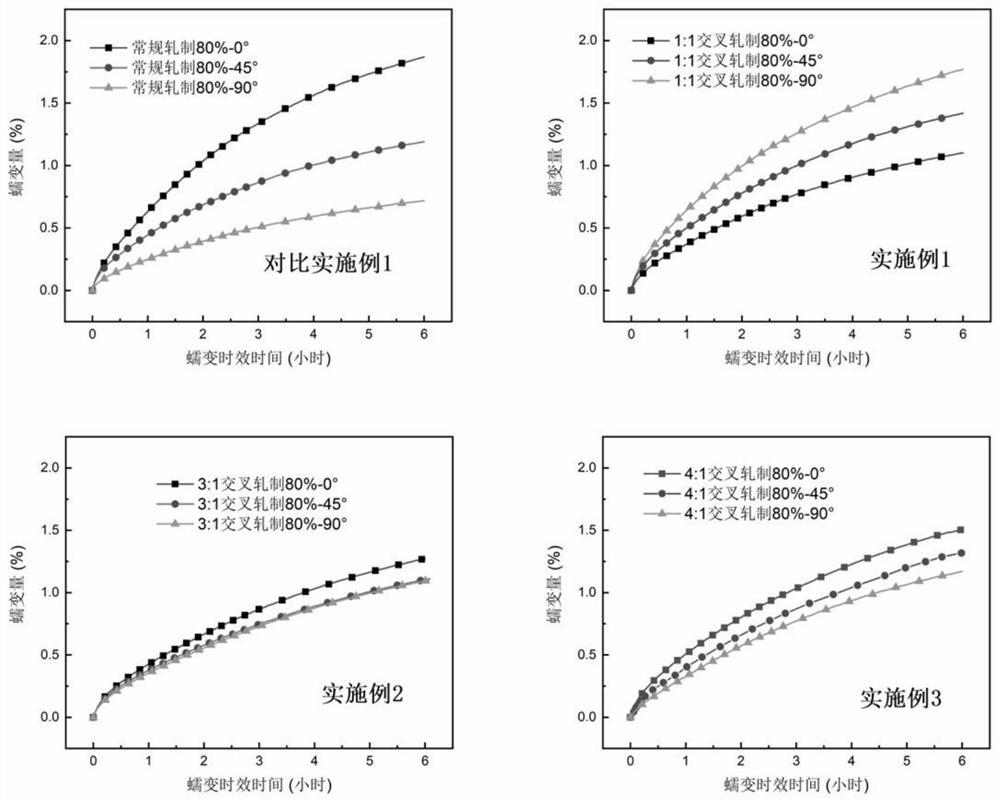

Embodiment 1

[0028] The 2219 aluminum alloy is subjected to solution treatment and water quenching in an air circulation resistance furnace to obtain an aluminum alloy plate; then it is subjected to non-equal cross cold rolling at room temperature, and the total thickness is reduced by 80%. The first and second steps of rolling The ratio of the deformation amount is 1:1, and then the creep experiment is carried out in the creep machine. The creep aging temperature is 140°C, the creep time is 6h, and the creep stress is 150MPa.

Embodiment 2

[0030] The 2219 aluminum alloy is subjected to solution treatment and water quenching in an air circulation resistance furnace to obtain an aluminum alloy plate; then it is subjected to non-equal cross cold rolling at room temperature, and the total thickness is reduced by 80%. The first and second steps of rolling The ratio of the deformation amount is 3:1, and then the creep experiment is carried out in the creep machine. The creep aging temperature is 140°C, the creep time is 6h, and the creep stress is 150MPa.

Embodiment 3

[0032] The 2219 aluminum alloy is subjected to solution treatment and water quenching in an air circulation resistance furnace to obtain an aluminum alloy plate; then it is subjected to non-equal cross cold rolling at room temperature, and the total thickness is reduced by 80%. The first and second steps of rolling The ratio of the deformation amount is 4:1, and then the creep experiment is carried out in the creep machine. The creep aging temperature is 140°C, the creep time is 6h, and the creep stress is 150MPa.

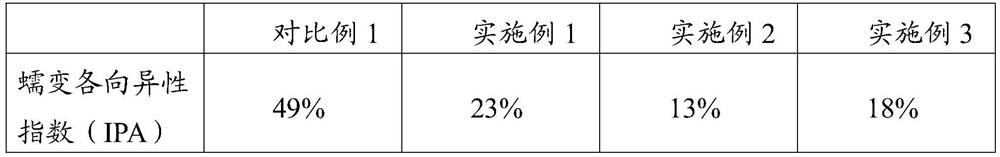

[0033] The creep anisotropy index of table 1 comparative example 1 and embodiment 1-3

[0034]

[0035] Table 1 shows the creep anisotropy index of 2219 aluminum alloy after creep aging forming obtained by using the conventional rolling method and the unequal cross rolling method of the present invention. figure 1 Is the creep curve of the comparative examples and some examples. It can be found that the creep anisotropy of the aluminum alloy treated by the non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com