Converter Transformer Partial Discharge Model Operating Mechanism

A converter transformer and partial discharge technology, which is applied in the field of converter transformer partial discharge model operating mechanism, can solve the problems of long time interval, inability to realize the pressurization mode of the needle plate discharge model, cumbersome operation steps, etc., so as to reduce the repetitive workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technology of the present invention will be described in detail below with reference to the specific embodiments. It should be understood that the following specific embodiments are only used to help those skilled in the art to understand the present invention, but not to limit the present invention.

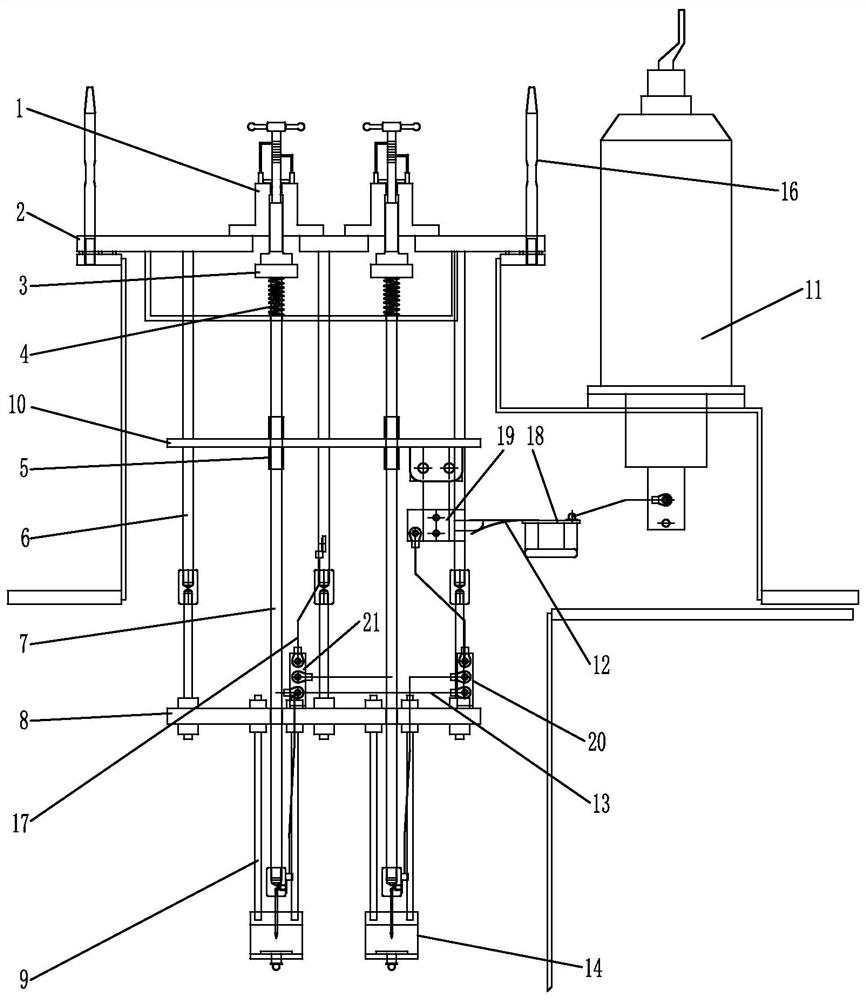

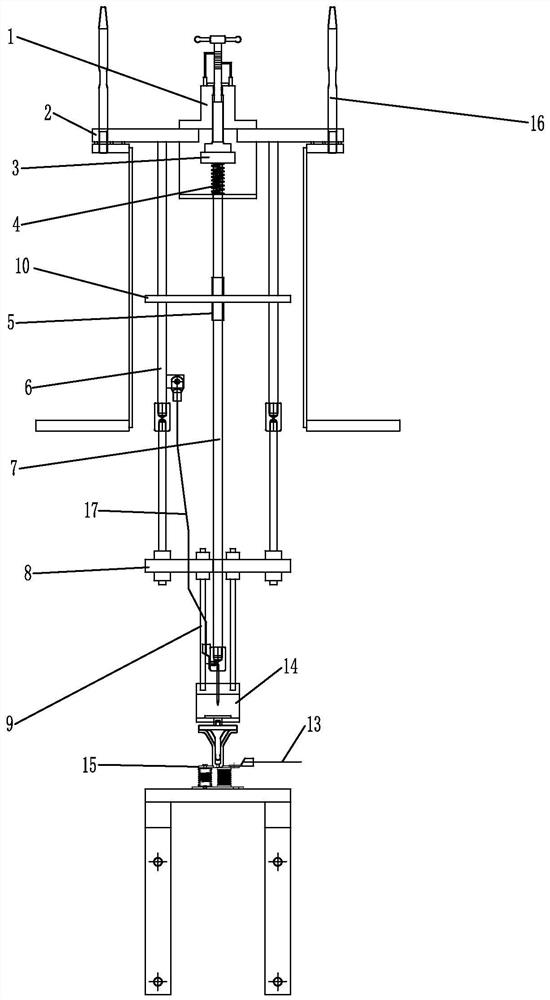

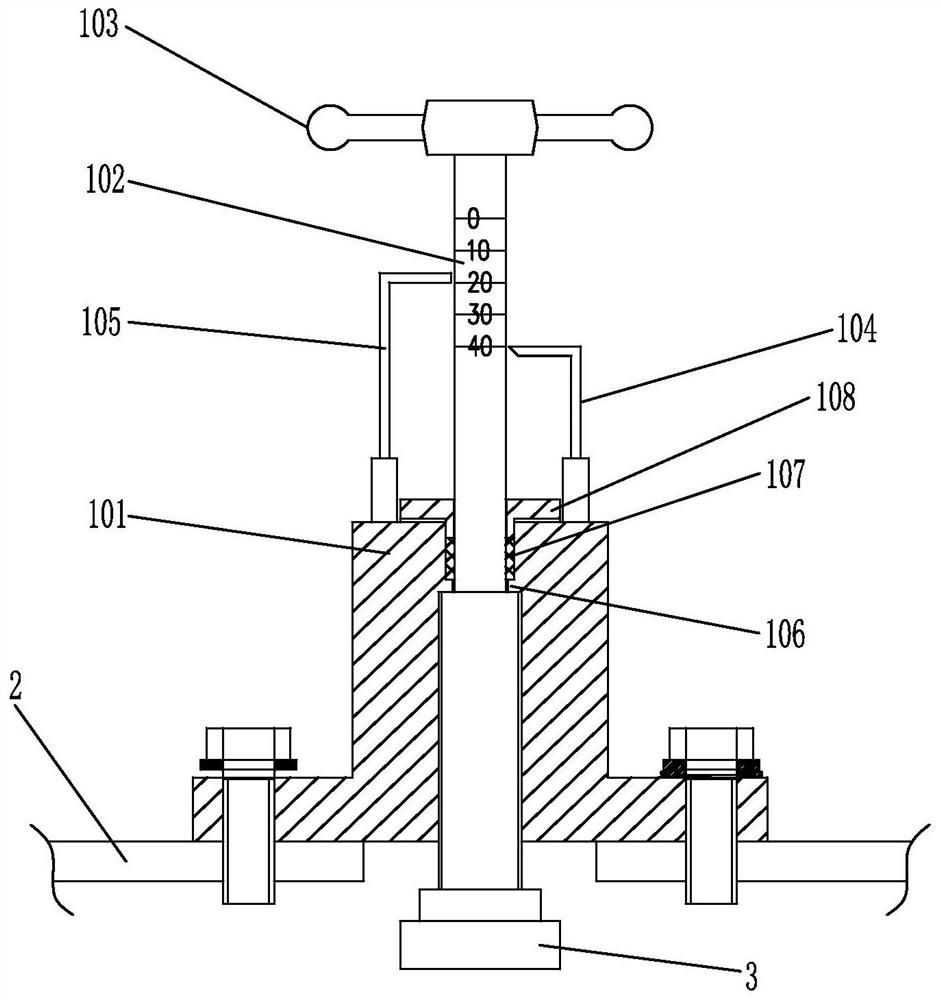

[0041] like Figure 1-3 The shown operating mechanism of the partial discharge model of the converter transformer is composed of a fixed frame and an electrode spacing adjusting device 1 installed on the fixed frame.

[0042] The fixed frame is composed of a fixed installation rod 6 with an adjustable length, an insulating member 8, an insulating fixed rod 9 and a mounting flange 2. One end of the fixed installation rod 6 is fixedly connected to the insulating member 8, and the other end is connected to the installation method. The flange 2 is fixedly connected, and the mounting flange 2 is fixed on the top cover of the transformer oil tank.

[0043] The electrode spa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com