Carbon powder conveying mechanism of laser printer

A technology of laser printers and conveying mechanisms, applied in optics, electrical recording technology using charge graphics, equipment using electrical recording technology using charge graphics, etc., can solve the problems of powder leakage, pollution of printed images, high replacement costs, etc., to avoid Toner stuck or leaked, improved printing quality, and low replacement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

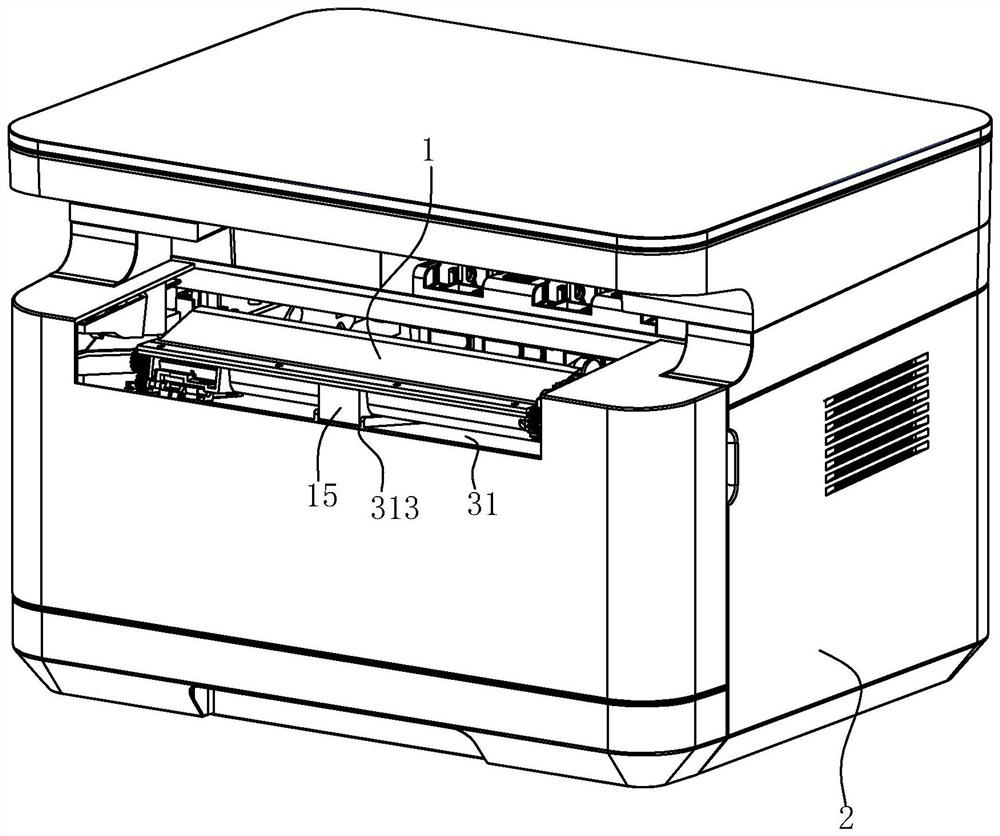

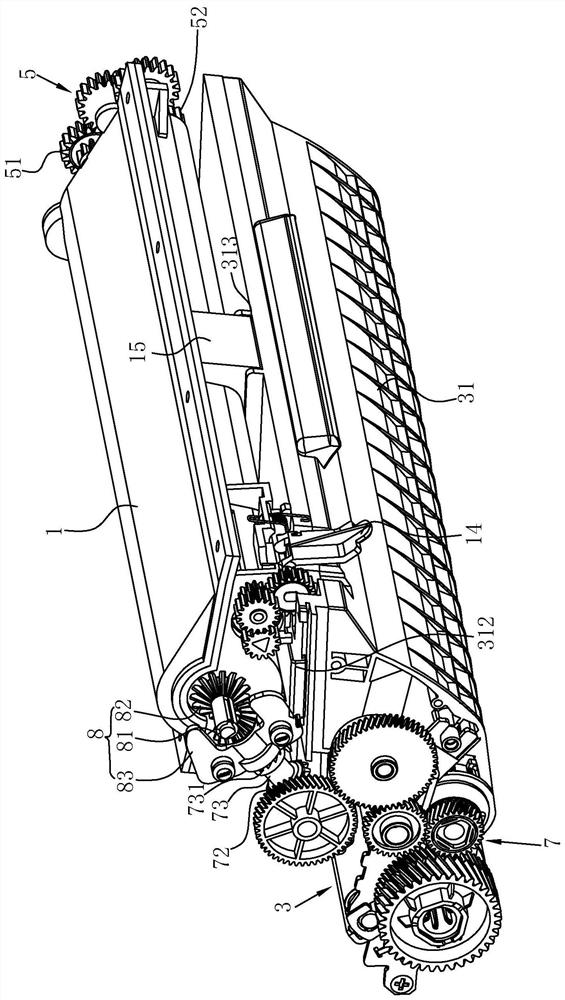

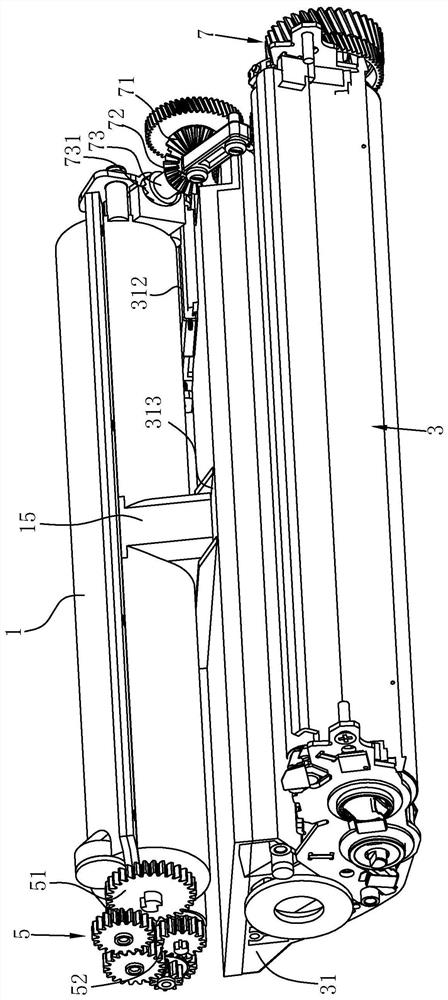

[0027] Such as Figure 1 to Figure 5 As shown, a toner delivery mechanism of a laser printer in this embodiment includes a toner box 1 , a delivery member 4 , and a drive assembly 5 . The powder bin box 1 can be independently disassembled and arranged in the printer casing 2. The powder bin box 1 is matched with the toner bin 31 of the toner cartridge main body 3 and communicated with the toner bin 31. The powder bin box 1 is used for storing toner and Toner is fed into the toner hopper 31 . The conveying member 4 is arranged in the toner box 1 for pushing and transporting the toner in the toner box 1 to the toner box 31 . The driving assembly 5 is connected with the conveying member 4 and drives the conveying member 4 to carry out toner conveying action.

[0028] The toner cartridge main body 3 is a toner cartridge assembly in the prior ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap