Method and system for measuring liquid level height of material in material stirring tank

A technology of liquid level and measurement method, applied in image data processing, instruments, 3D modeling, etc., can solve the problems of large randomness of discrete points, threat of staff, inattention, etc., to avoid low reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

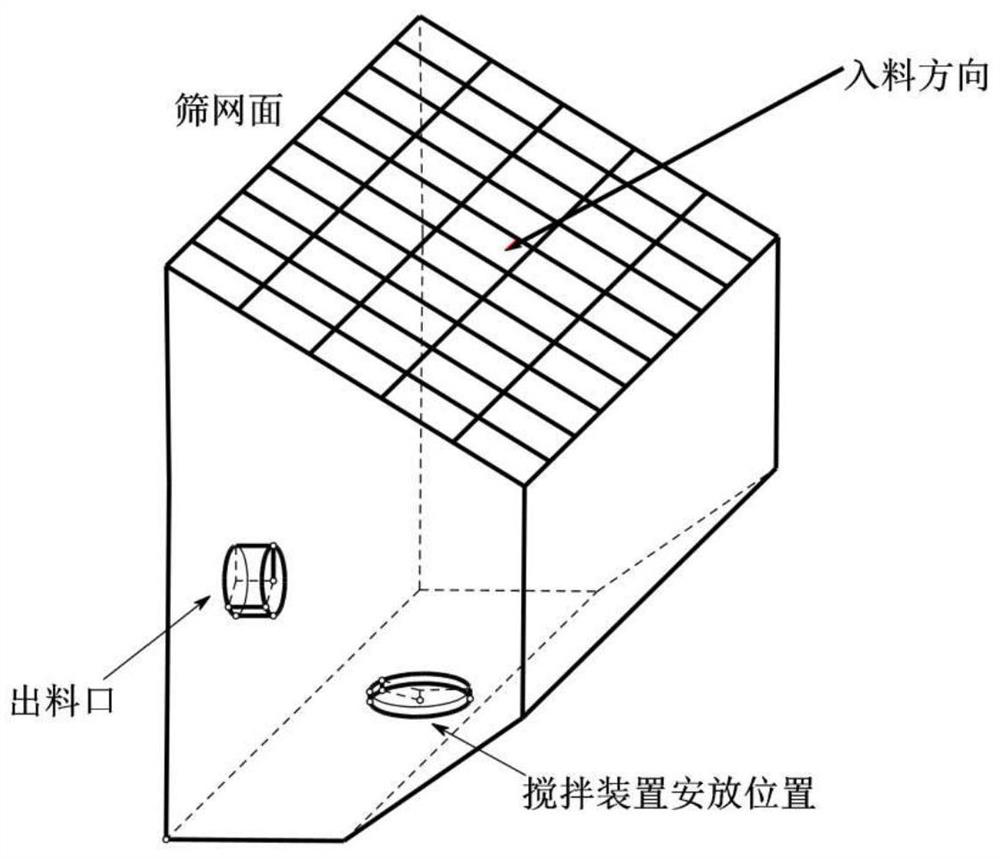

[0067] The method for measuring the liquid level height of the material in the material stirring tank according to the embodiment of the present invention comprises the following steps:

[0068]Step 1. Data preparation. The data required by this method include: real-time collection of laser radar point cloud data in the dynamic process of continuously conveying materials into the material mixing tank; user input filtering parameters, the value of the parameters is based on the actual situation of the point cloud, point cloud filtering accuracy requirements, hardware The environment can be determined flexibly.

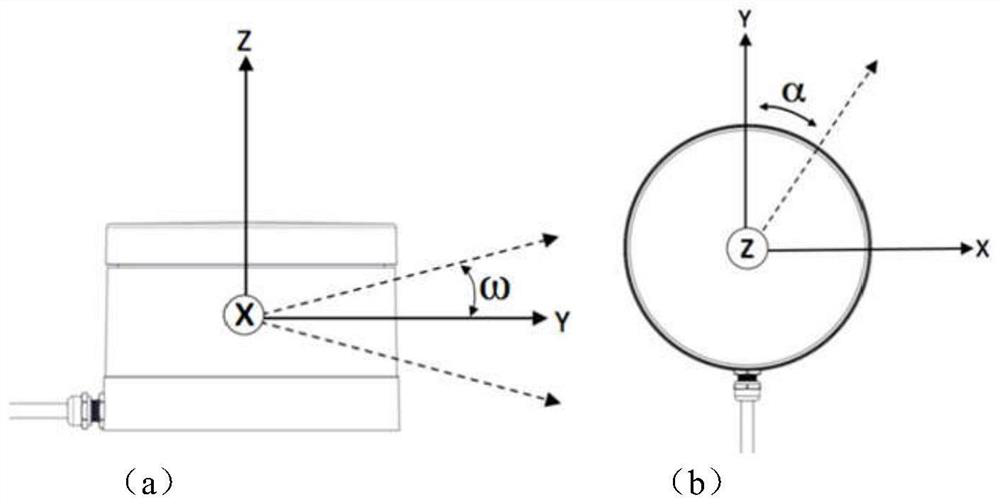

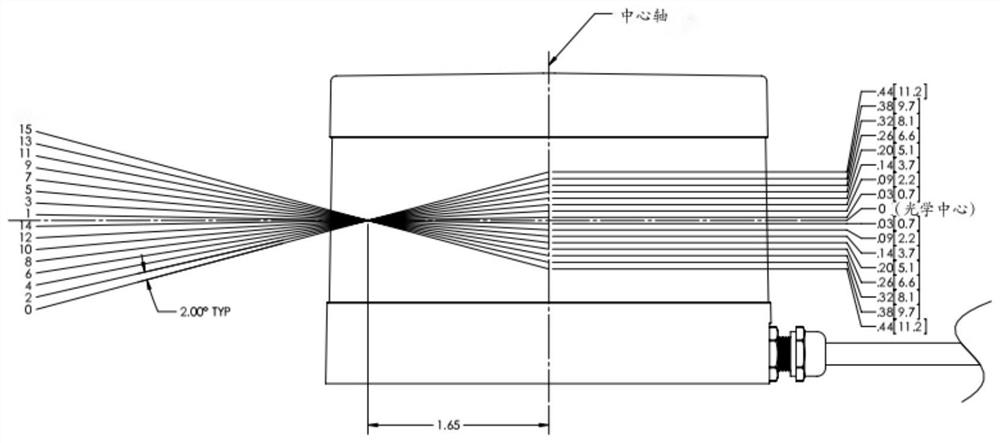

[0069] Step 2. Calibrate the key points of the material stirring tank in the laser radar coordinate system, and perform the first filtering on the original 3D point cloud data according to the position coordinate range of the key points of the material stirring tank model, and filter out the parts other than the stirring tank model All point cloud data, only keep the p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap