USB socket and manufacturing method thereof

A manufacturing method and technology of connectors, which are applied to the assembly/disassembly of contacts, fixing/insulating contact members, electrical components, etc., can solve the problems of simultaneous fixing in the upper and lower directions, high cost of mold opening, and inability to realize one-time or Double injection molding and other issues to achieve good appearance and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

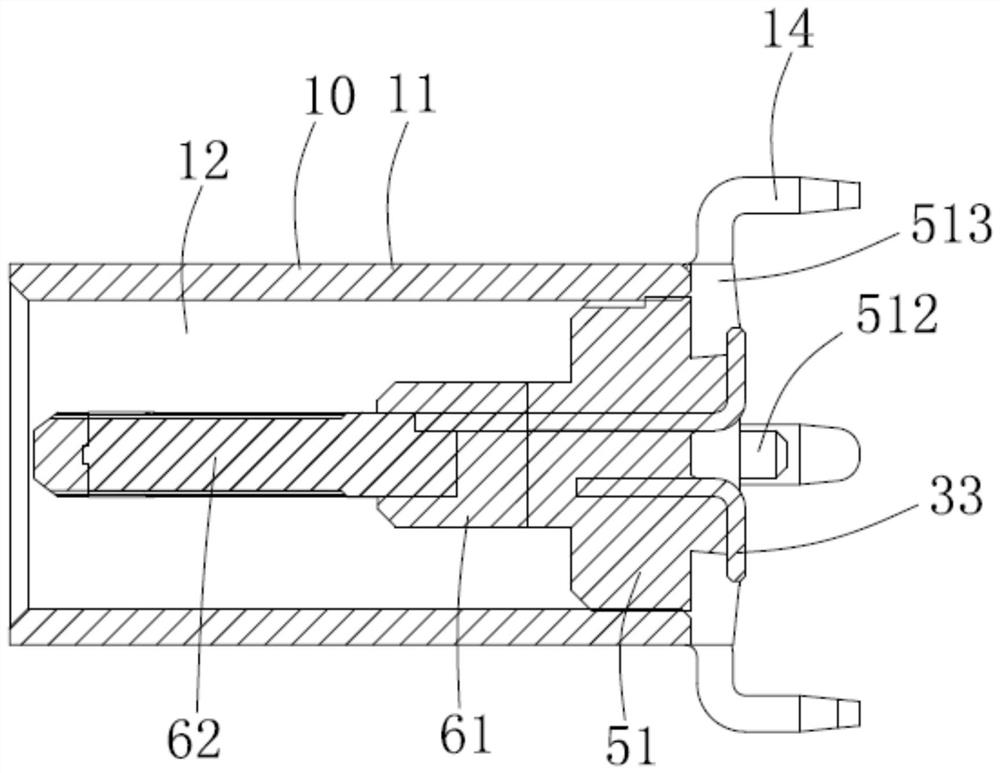

[0030] In order to make the objectives, technical solutions and advantages of the present application clearer, the technical solutions of the present application will be clearly and completely described below with reference to the specific embodiments of the present application and the corresponding drawings. Obviously, the described embodiments are only a part of the embodiments of the present application, but not all of the embodiments.

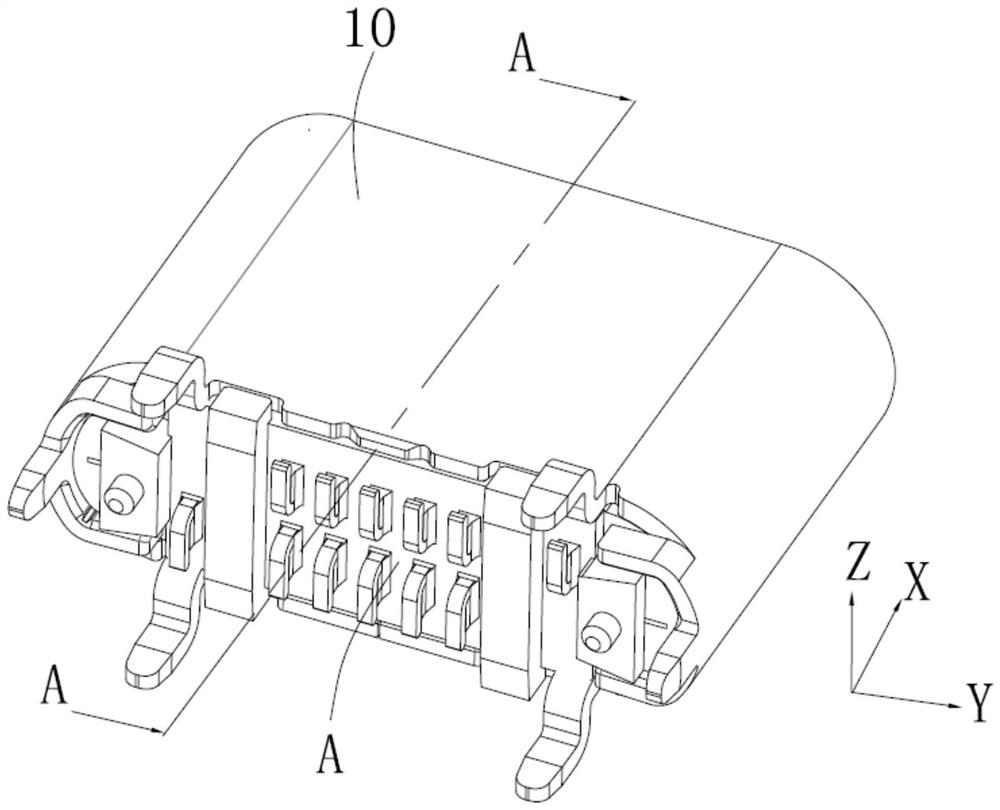

[0031] This application starts with figure 1 The indicated X direction is above the vertical direction (vertical direction), the Y direction is the left-right direction (horizontal direction), and the Z direction is the front-rear direction (vertical direction).

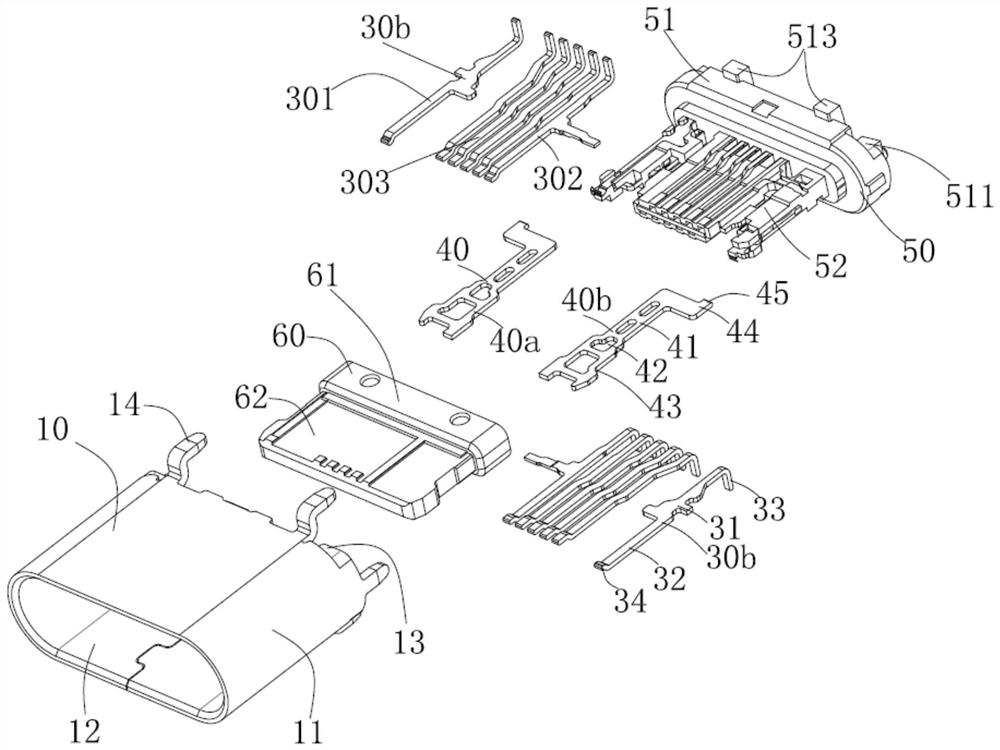

[0032] see Figure 1 to Figure 7 As shown, the USB socket of the present application includes a connector A and a metal shell 10 sleeved outside the connector A.

[0033]The metal shell 10 includes an annular shell 11 surrounding a cavity 12 penetrating up and down, hooks 13 ben...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap