Center part supporting mechanism and machining fixing device of engine shell

A technology for engine casings and supporting mechanisms, which is applied to positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as concave deformation and easy loosening, and achieves prevention of concave deformation, easy loosening, and good adaptability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

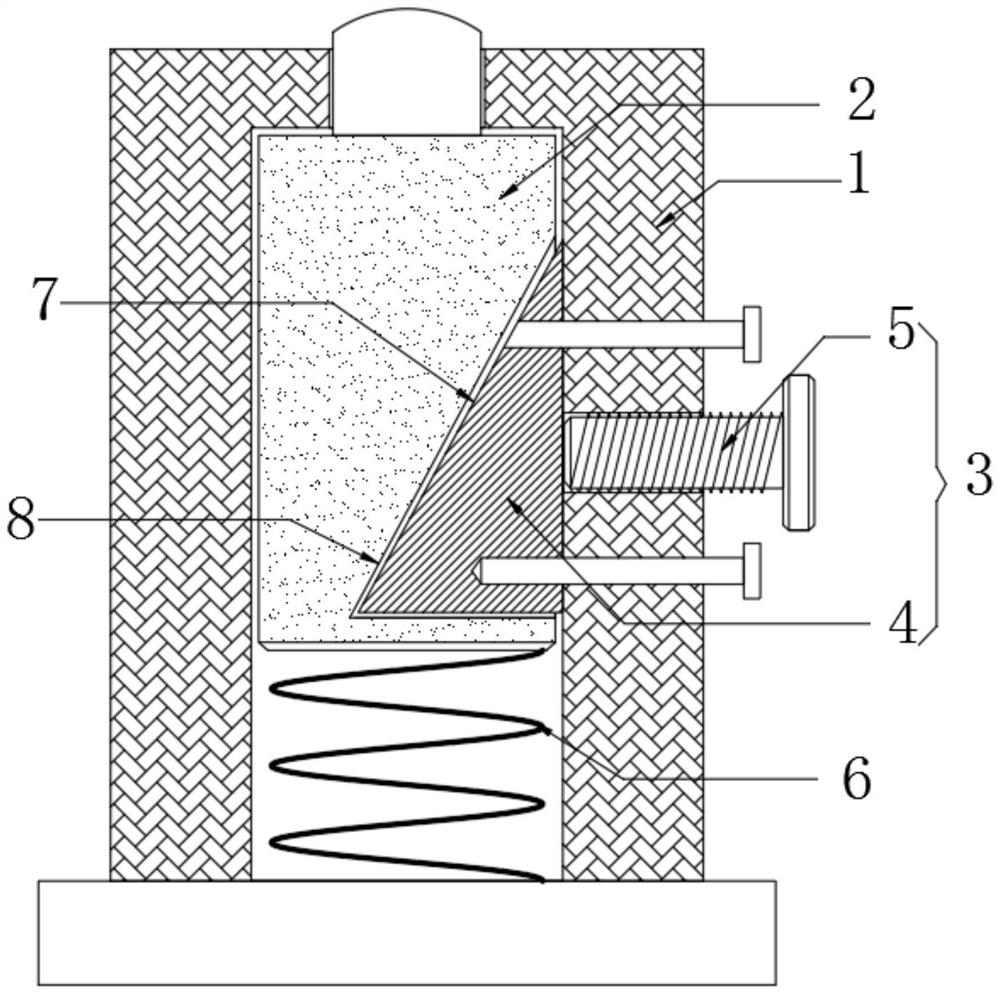

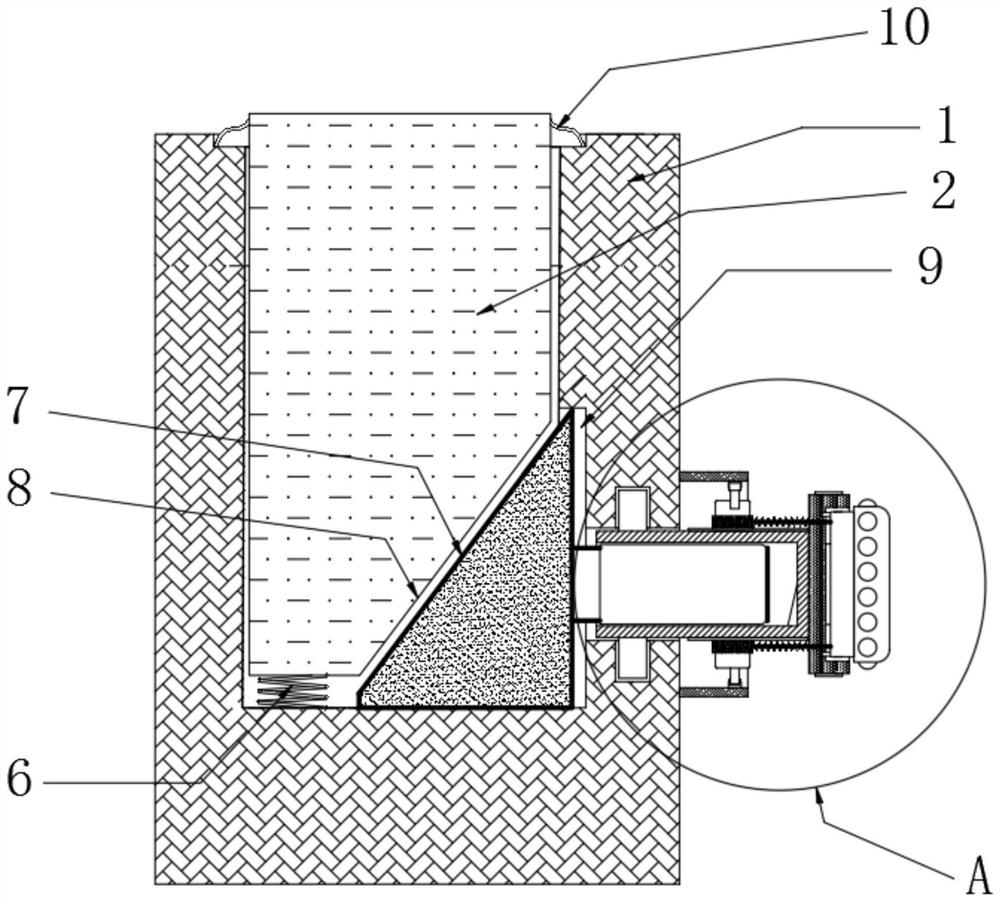

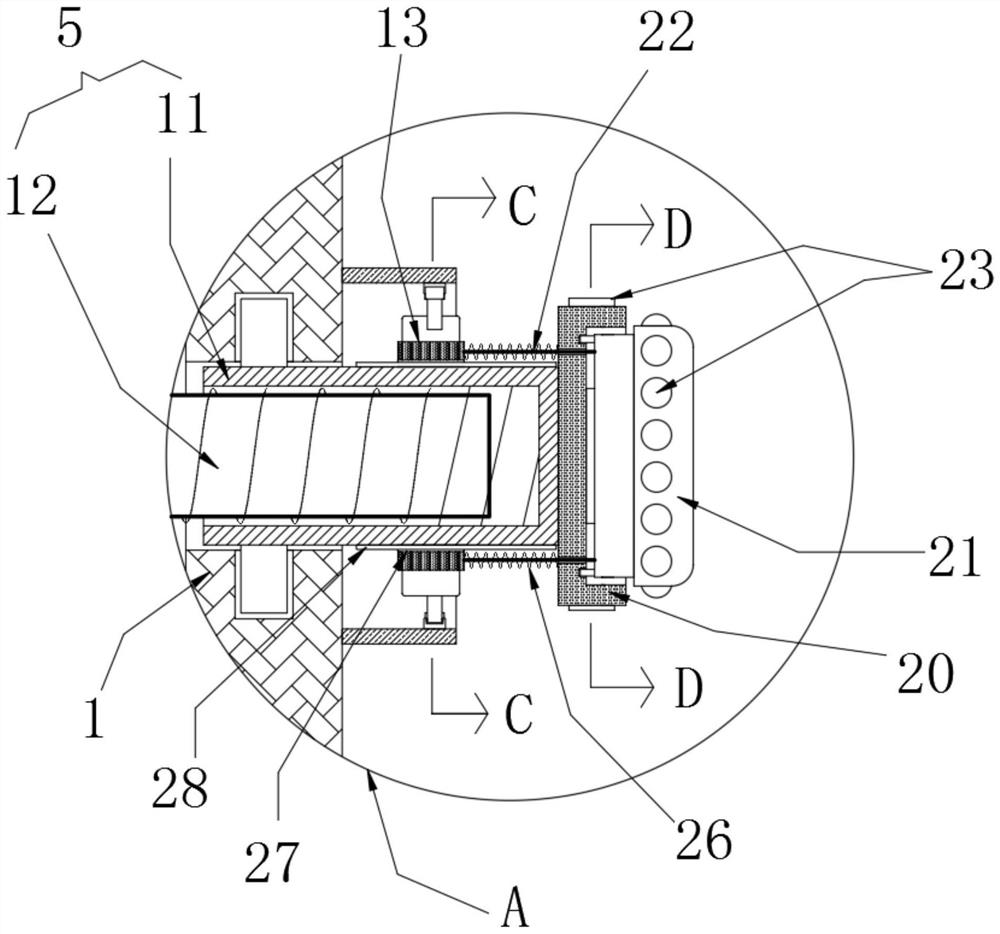

[0033] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0034] see Figure 1-8 The embodiment of the present invention provides a support mechanism for the machining center of the engine casing, including a sleeve 1 and a pillar 2, the pillar 2 is movably socketed in the sleeve 1, and the top of the pillar 2 is used to support the center of the engine casing position, the sleeve 1 and the pillar 2 are also connected by a spring 6, and also include a support assembly 3, and the support adjustment assembly 3 includes:

[0035] Inclined block 4, which has a first support inclined plane 7;

[0036] Adjusting rod 5, which is screwed with sleeve 1;

[0037] The rotation of the adjustment rod 5 drives the ramp block 4 so that the first support ramp 7 and the second support ramp 8 on the pillar 2 wedge-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com