Suspension freight turnout steel rail linear section rail locking device and installation process thereof

A rail and segment lock technology, which is applied to the hydraulic equipment used to manipulate turnouts or line breakers, the locking mechanism used for turnouts, transportation and packaging, etc., can solve the problems of low shape accuracy, difficult processing and heat treatment, and low precision And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

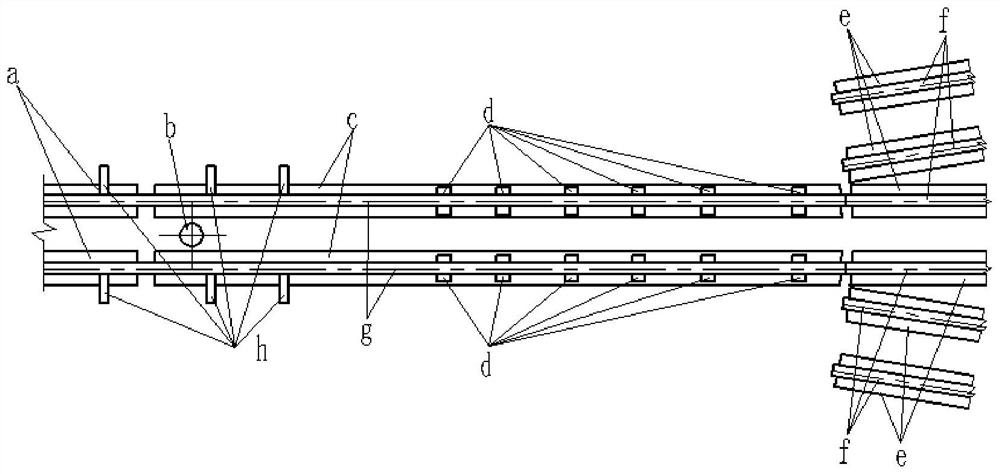

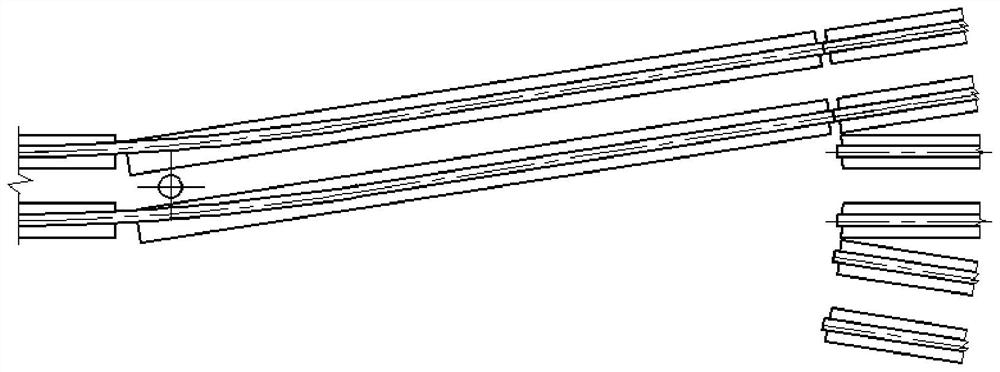

[0058] Such as Figure 1-2 shown in figure 1 In the structural schematic diagram of the suspended freight monorail three-opening turnout, the fixed monorail open box track beam a is two I-shaped beams ( Figure 1-2Simplified in , the same below), the rotatable single-track open box-shaped track beam c is also two I-shaped beams arranged in parallel in space; the three-track open box-shaped track beam e is composed of six mutually fixed The two I-shaped girders in the center of the three-track open box track beam e are arranged in parallel in space; the two I-shaped girders on both sides are respectively arranged in parallel in space; the central I-shaped girder and the two sides The included angle between the I-shaped girders is just equal to the line change angle of the turnout. The two change-line rails g are respectively placed on the upper surface of the lower bottom plate inside the I-shaped girder (inside the vertical plate of the I-shaped girder) of the fixed monorail...

Embodiment 2

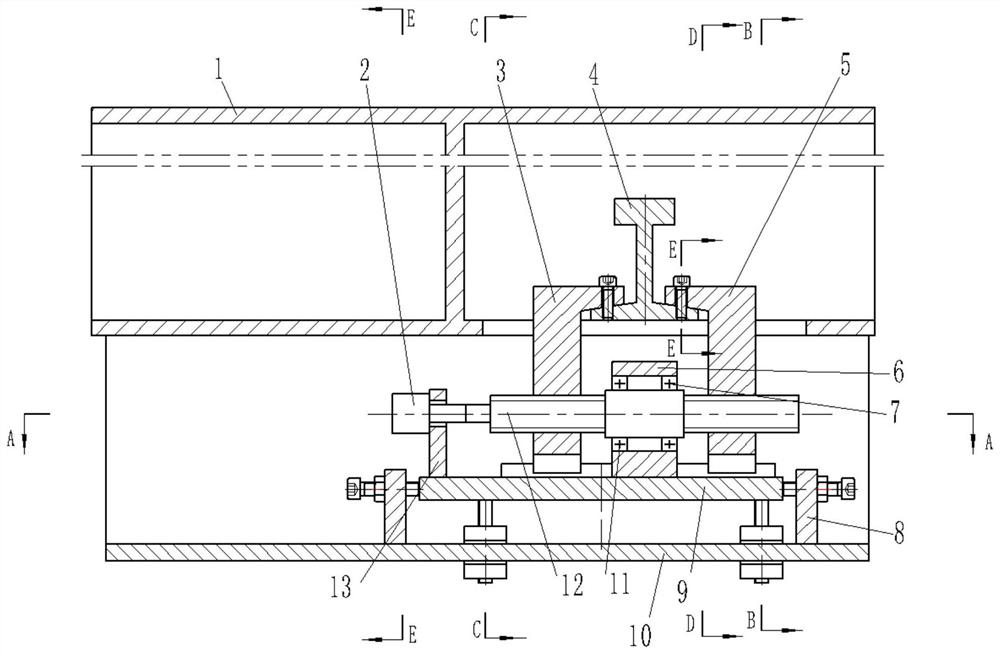

[0068] On the basis of Embodiment 1, the present invention also provides an installation process of the rail locking device for the straight section of the rail of the suspension freight turnout, including the installation process and the working process.

[0069] 1. The installation process includes the following steps:

[0070] 1) Remove the two jaw set screws 44.

[0071] 2) The rail 4 is placed at a suitable position of the open box-shaped track beam 1, and the straight line section to be fixed of the steel rail 4 is fixedly connected with the open box-shaped track beam 1.

[0072] 3) The movable straight section of the rail 4 is connected (detachable) to the open box-shaped track beam 1 through a universal clamp, such as a screw clamp and the like.

[0073] 4) Reversely start the hydraulic motor 2 to drive the left and right screw 12 to rotate, so that the locking claw A3 moves to the left, and the locking claw B5 moves to the right, so that the two claws are opened. When ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com