Updip freezing pipe sleeve construction exhaust device and updip freezing pipe sleeve construction exhaust method

A technology of exhaust device and exhaust method, applied in the direction of pipes/pipe joints/pipes, infrastructure engineering, pipe components, etc., can solve problems such as gas storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

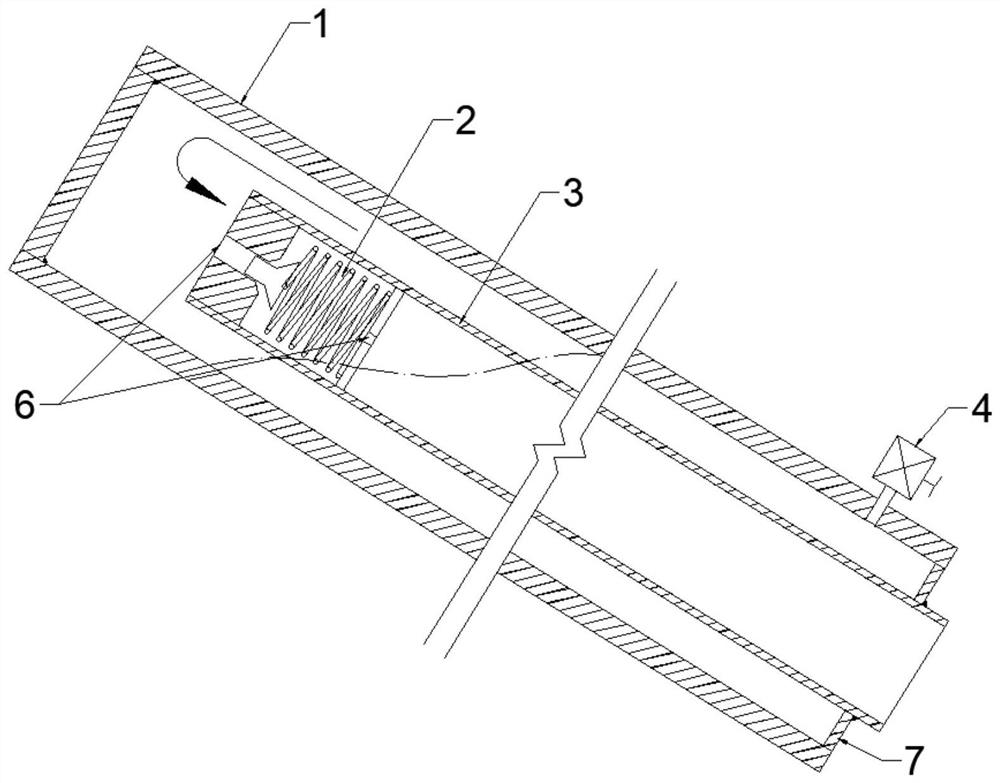

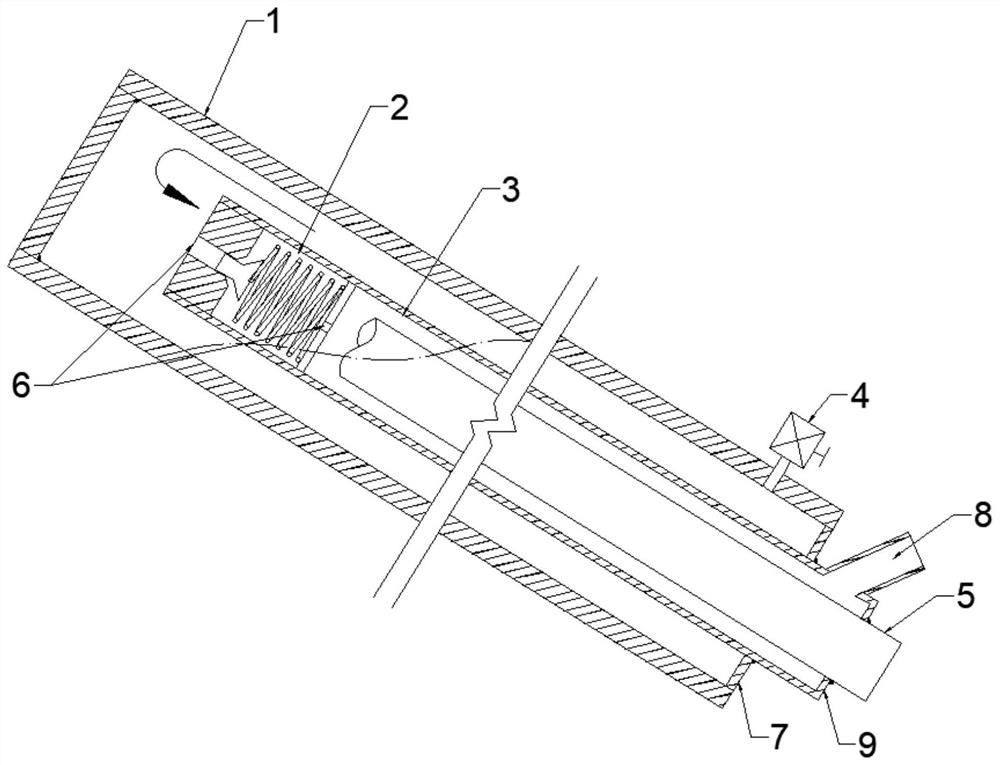

[0037] Such as figure 1 and figure 2 As shown, the exhaust device for the casing construction of the upwardly inclined freezing pipe includes a one-way valve 2, a casing 3, a ball valve 4, a liquid supply pipe 5 and a liquid return pipe 8;

[0038] The one-way valve 2 is fixedly installed on the first end of the sleeve 3;

[0039] The first end of the sleeve 3 extends into the freezing tube 1, and the outer wall of the second end of the sleeve 3 is sealed with the second end of the freezing tube 1 by a first annular sealing plate 7 fixed connection;

[0040] The ball valve 4 is fixedly installed on the outer pipe wall of the second end of the freezing pipe 1; Pass.

[0041] The first end of the liquid supply pipe 5 extends into the casing 3, and the second end nozzle of the casing 3 passes through the second annular sealing plate 9 and the outer wall of the liquid supply pipe 5. The connection is sealed and fixed by welding;

[0042] The liquid return pipe 8 is provided...

Embodiment 2

[0046] The exhaust method for the casing construction of the upwardly inclined frozen pipe is to use the exhaust device for the casing construction of the upwardly inclined frozen pipe of Embodiment 1 to carry out the method for exhausting the construction of the casing for the upwardly inclined frozen pipe, comprising the following steps:

[0047] A. Preparation of auxiliary drainage: prepare auxiliary drainage for freezing pipe 1 exhaust according to construction requirements;

[0048] B. Installation of one-way valve 2: fixedly install one-way valve 2 on the first end of casing 3;

[0049] C, the installation of the sleeve pipe 3: the sleeve pipe 3 is lowered into the freezing pipe 1 by means of pushing, and two adjacent sleeve pipes 3 are connected by welding;

[0050] D. Sealing treatment: fix the first annular sealing plate 7 between the sleeve pipe 3 and the freezing tube 1, and seal to form the first cavity; the formation of the first cavity can seal the gas accumulate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com