Cloth rolling device for producing sweat-releasing blended fabric

A blended fabric and sweat-wicking technology, applied in textiles, textiles, papermaking, looms, etc., can solve problems such as fabric wrinkles, inability to adapt to different fabric requirements, and difficulty in controlling the tightness of cloth rolls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

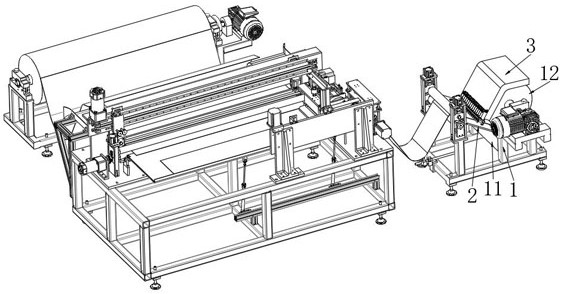

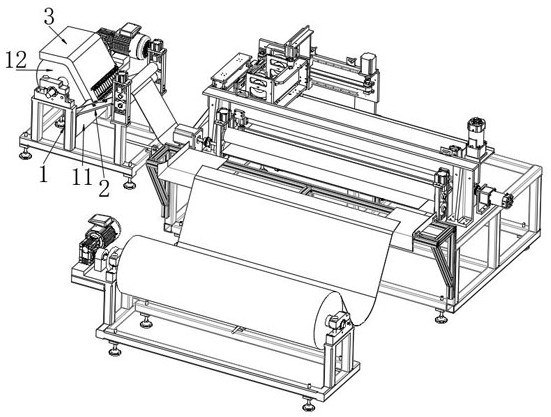

[0030] Such as Figure 1-10 As shown, the cloth rolling device for producing sweat-wicking blended fabrics of the present invention includes a frame 1, a load plate 2, a dust cover 3, a cloth strip body 10, a mounting plate 11 and a reel 12, and the cloth strip body 10 is wound on the reel 12, the mounting plate 11 is fixedly connected with the frame 1;

[0031] The dust cover 3 is provided with a detection mechanism 4 near the outer surface of the bearing plate 2, and the detection mechanism 4 is used to detect the flatness of the strip body 10 on the surface of the bearing plate 2;

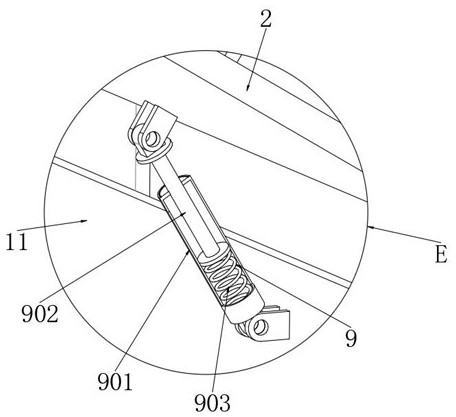

[0032] The upper and lower sides of the bearing plate 2 are provided with a rotating mechanism 9, and the rotating mechanism 9 is used to drive the dust cover 3 to change the direction of rotation as the winding diameter of the strip body 10 increases.

[0033] The roll cloth to be processed is divided into several cloth strip bodies 10 by the cutting device, and the cloth strip bodies 10 divid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com