Laser device fixing device and method for achieving temperature self-adaption through same

A technology of fixing devices and lasers, applied in feeding devices, large fixed members, automatic control devices, etc., can solve problems affecting surface processing quality, unstable cutting temperature, etc., and achieve sensitive and convenient self-adaptive process, easy to control, temperature control Compare the exact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

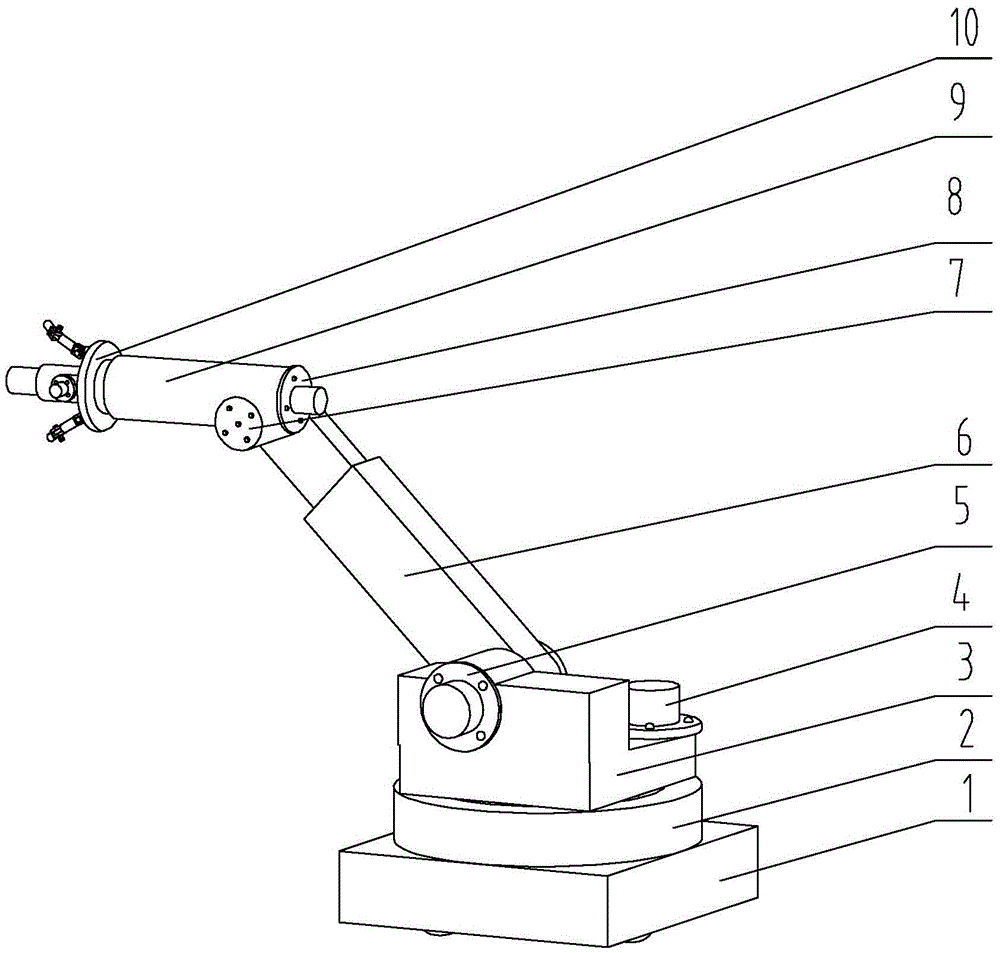

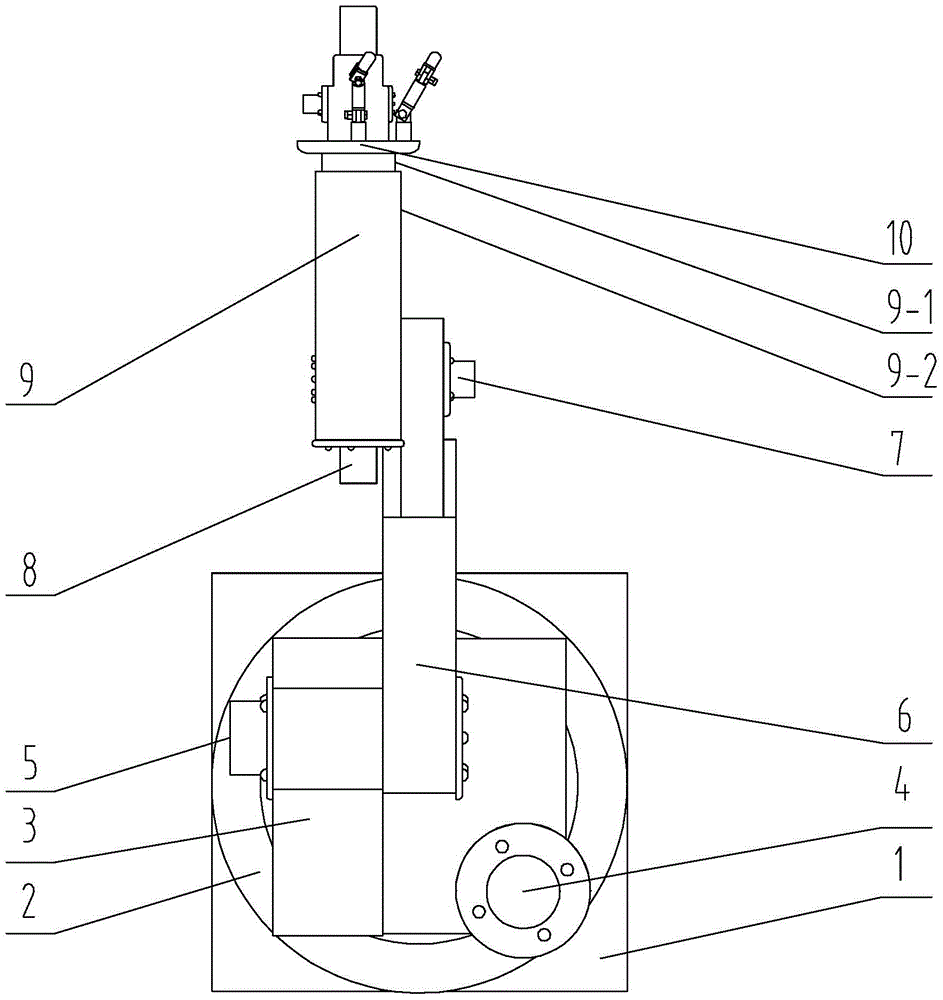

[0027] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment. A laser fixing device described in this embodiment includes a base 1, a rotary mechanism, an extension mechanism, an adjustment mechanism, and a launch mechanism. The launch mechanism, the adjustment mechanism, the extension mechanism, and the rotation mechanism are arranged in sequence from front to back. The mechanism is set on the base 1,

[0028] The rotary mechanism includes a rotary base 2, a rotary table 3 and a first rotary motor 4, the rotary base 2 is fixed on the base 1, the rotary table 3 is arranged on the upper end surface of the rotary base 2, and the rotation between the rotary table 3 and the rotary base 2 connection, the first rotary motor 4 is vertically arranged on the rotary table 3, the housing of the first rotary motor 4 is fixedly connected to the rotary table 3, and the rotating shaft of the first rotary motor 4 is connected to the rotary seat 2,

[0029] ...

specific Embodiment approach 2

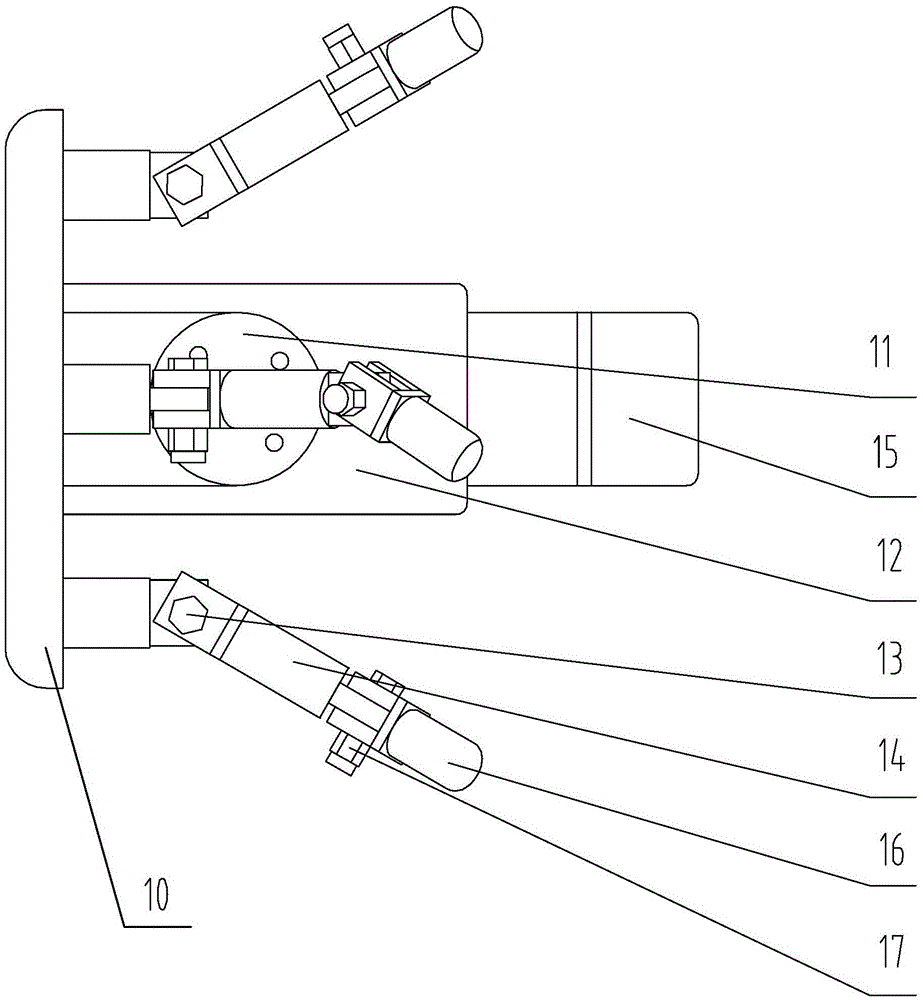

[0032] Specific implementation mode two: combination Figure 1 to Figure 3 Describe this embodiment, the rotating shaft 14 in this embodiment is connected to the connecting end surface 10 through the first stud 13, the infrared sensor 16 is connected to the rotating shaft 14 through the second stud 17, and the second stud 17 is connected to the rotating shaft 14. A double-ended stud 13 is vertically arranged with the second double-ended stud 17 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0033] Specific implementation mode three: combination Figure 1 to Figure 3 This embodiment will be described. In this embodiment, the inner housing 9-1 and the outer housing 9-2 are connected by bearings. The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com