Ground breaking device

A ground and positioning hole technology, applied in construction, building maintenance, instruments, etc., can solve the problems of high penetration requirements, low destruction efficiency, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

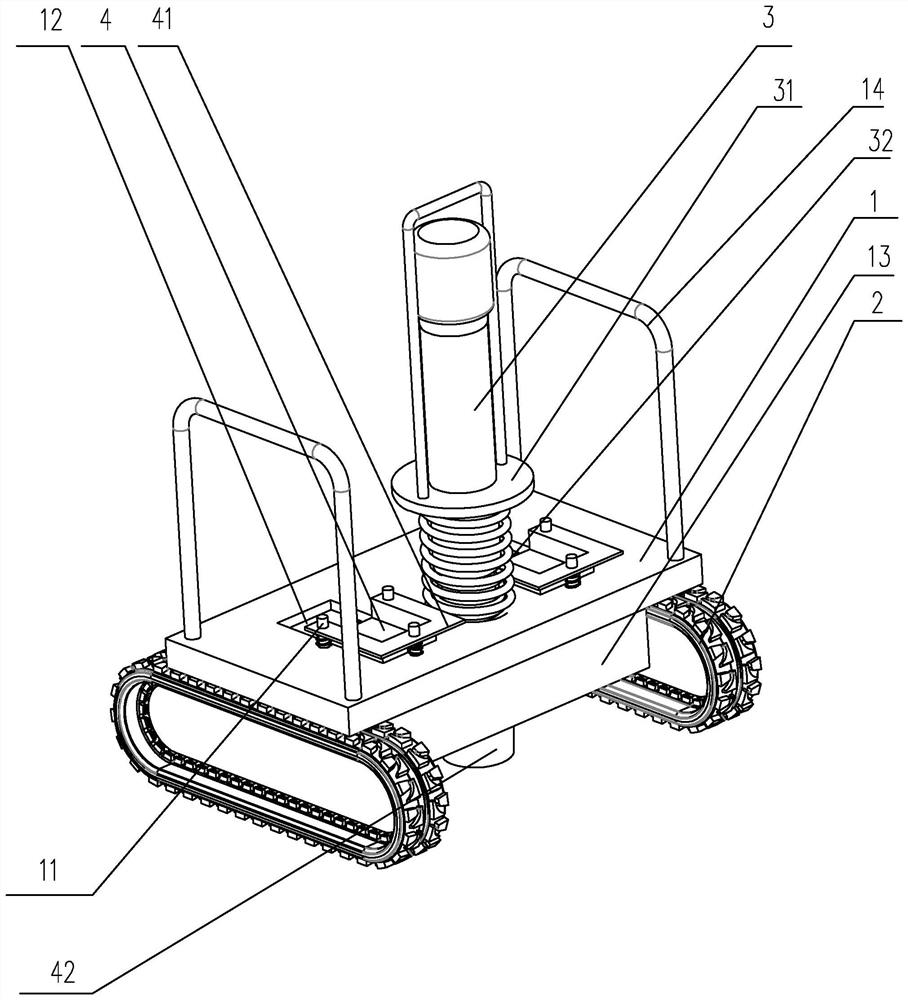

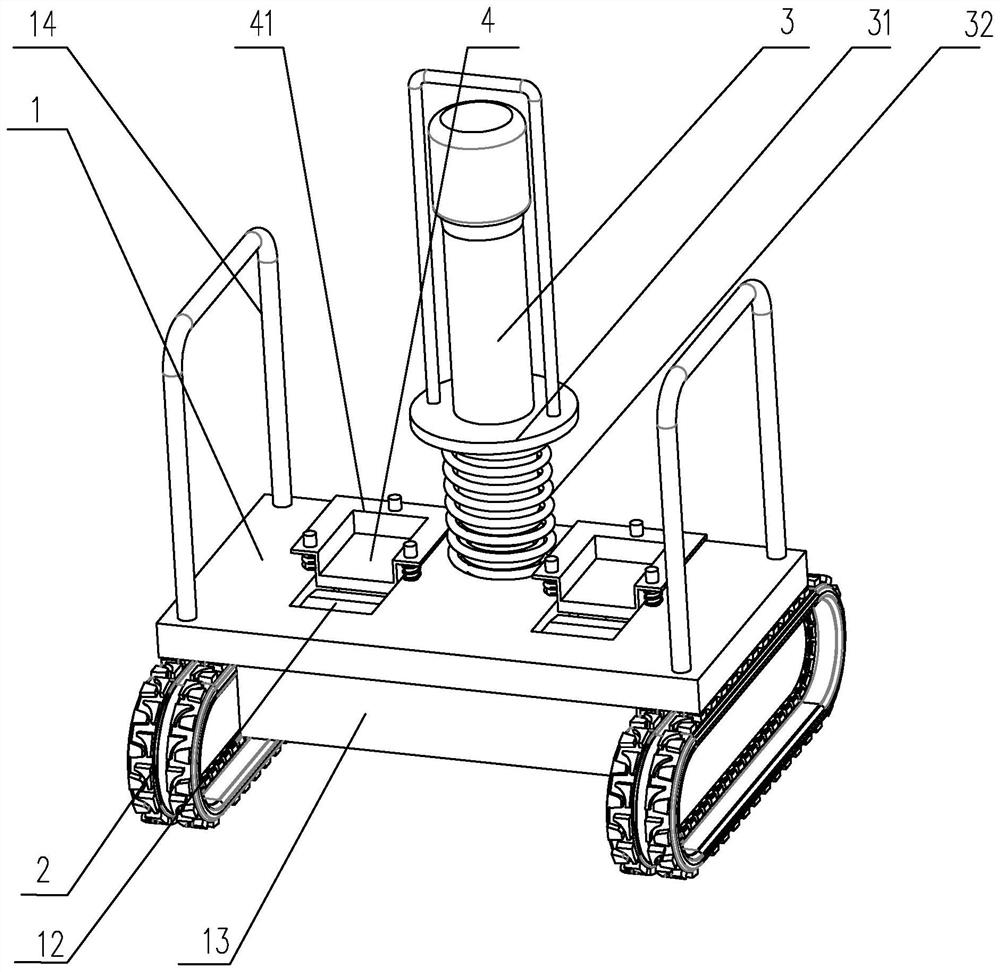

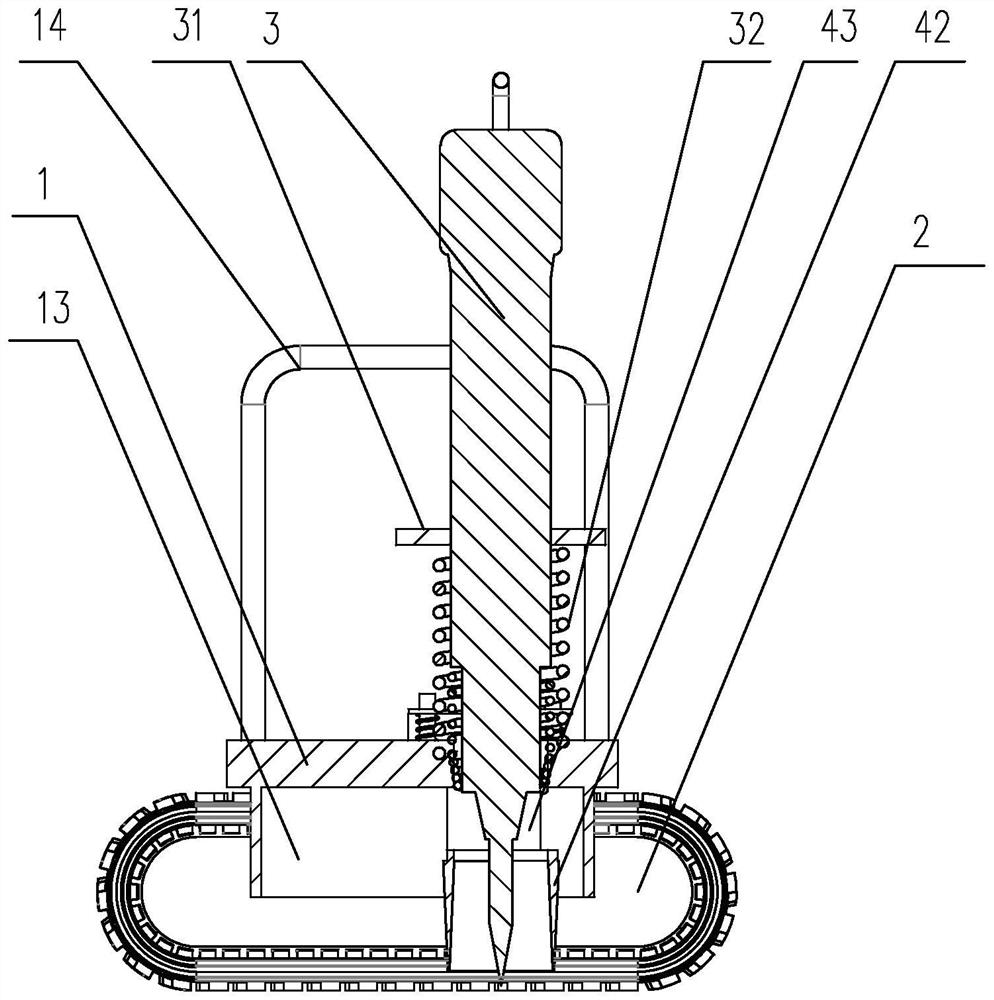

[0019] The embodiment of ground breaking device of the present invention is such as Figure 1 to Figure 3 Shown: includes a base 1, track wheels 2 are provided on both sides of the base 1, a positioning hole is opened on the central axis of the base 1, a pneumatic pick 3 is pierced in the positioning hole, and the upper edge of the pneumatic pick 3 A positioning plate 31 is arranged in the circumferential direction, and a buffer spring 32 is also sleeved on the jack 3. The buffer spring 32 is arranged in conflict between the positioning plate 31 and the base 1, and the base 1 is on both sides of the positioning hole. Stepping grooves are respectively provided, and the stepping grooves include a forefoot groove and a heel groove 12, and the forefoot groove and the heel groove 12 are connected by a smooth connection surface, and a pedal 4 is slid along the height direction in the forefoot groove. , the pedal 4 is provided with a positioning flange 41 along the circumferential di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com