Photochromic film for automobile and manufacturing method thereof

A technology for a photochromic film and a manufacturing method, which is applied in the field of color-changing materials, can solve the problems of single pattern type and cannot meet the needs of consumers, etc., and achieves the effects of smooth edges, rich pattern display types and rich pattern styles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

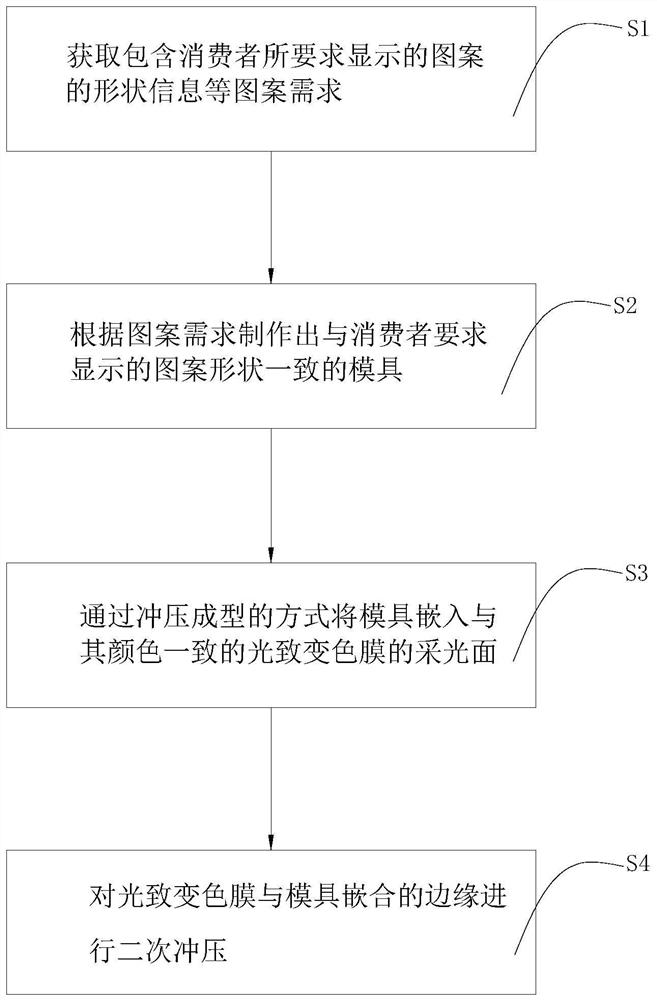

[0050] refer to figure 1 , the manufacture method of photochromic film for automobile comprises steps:

[0051] S1: Obtain pattern requirements including shape information of the pattern requested by consumers.

[0052] In this embodiment, the pattern requirement includes shape information of the pattern, color information of the pattern and size information of the pattern. The shape information represents the shape of the pattern, that is, the overall outline of the pattern, the color information of the pattern represents the color of the pattern, and the size information represents the size of the pattern.

[0053]Specifically, the shape and outline of the pattern can be obtained through the high-definition two-dimensional image of the pattern provided by the consumer, and the color information and size information can be obtained through the specified color and specified size proposed by the consumer. For example, the consumer provides a two-dimensional image of the "Merc...

Embodiment 2

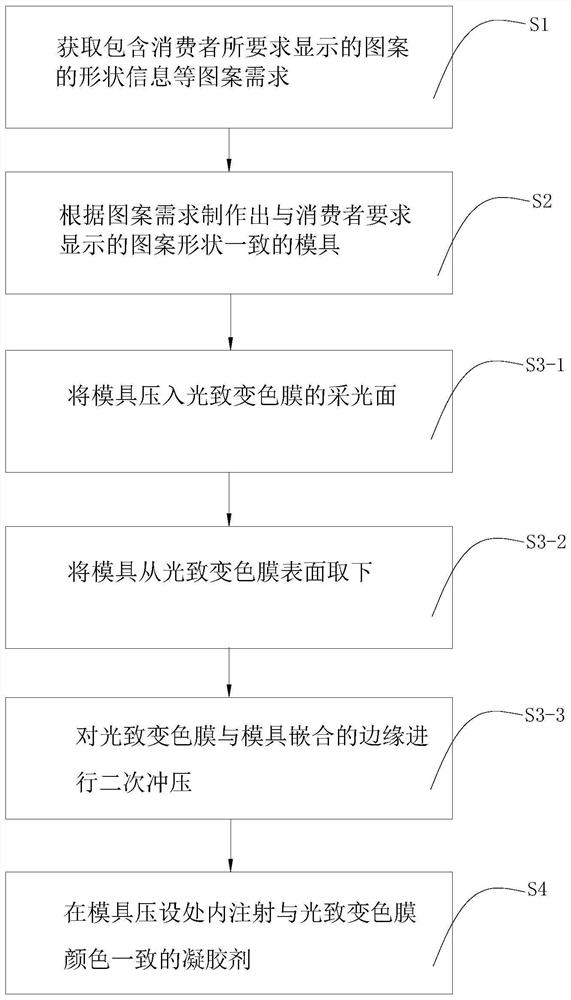

[0082] refer to figure 2 , this embodiment is different from the steps of embodiment 1 in that:

[0083] S2: After the step of "making a mold consistent with the shape of the pattern required by the consumer according to the pattern requirement", it includes steps:

[0084] S3-1: Press the mold into the lighting surface of the photochromic film;

[0085] In this embodiment, the active force of the hydraulic cylinder to the mold should be properly adjusted to be small, so as to prevent the mold from being difficult to remove after being pressed into the photochromic film.

[0086] S3-2: removing the mold from the surface of the photochromic film;

[0087] In this embodiment, after the photochromic film is taken off, a groove whose contour is consistent with the mold is formed at the press-in place of the mold.

[0088] S23-3: Injecting a gel agent in the same color as the photochromic film in the press setting of the mold.

[0089] In this embodiment, the gel agent is inje...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com