Method and device for assembling flywheel pair of camshaft of engine

A camshaft and engine technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the surface anti-rust effect, scratching the surface of the flywheel pair, and low work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but it should be understood that the protection scope of the present invention is not limited by the specific embodiments.

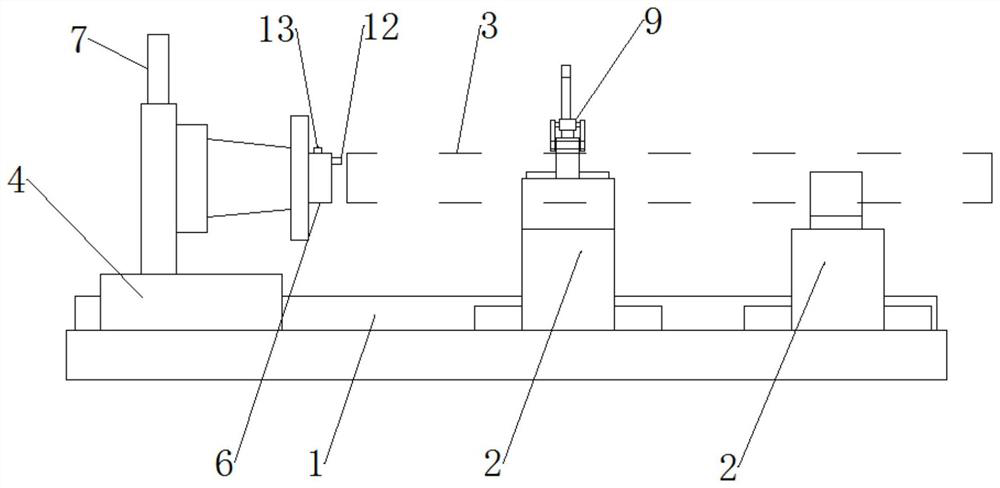

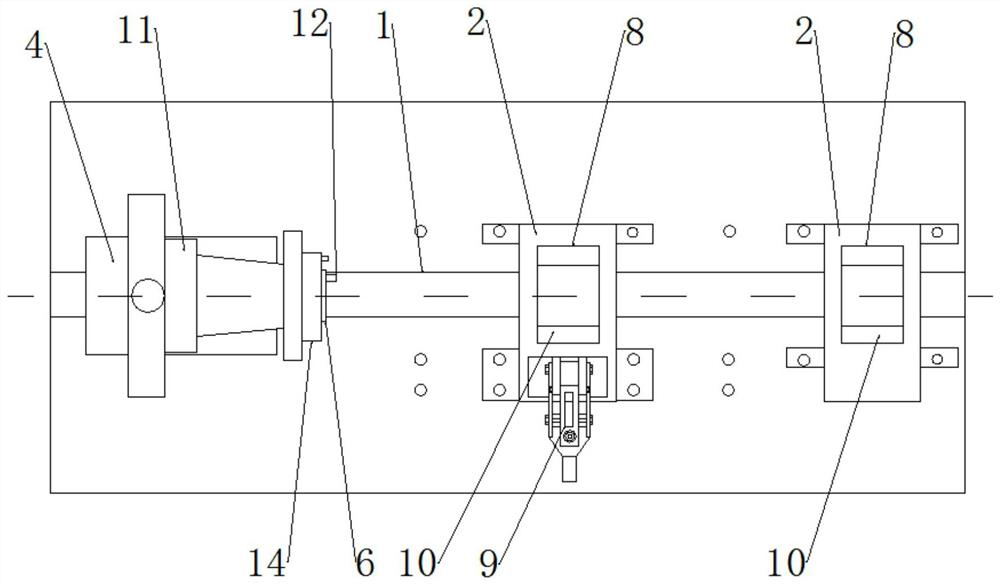

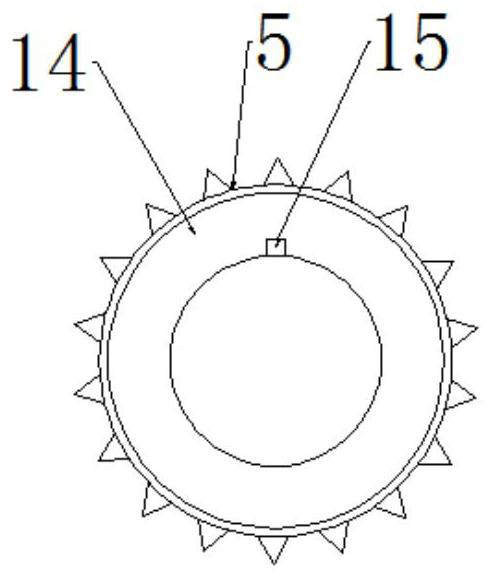

[0023] The specific embodiment of the present invention is as follows: Figure 1-4 As shown, a method for assembling an engine camshaft flywheel pair includes the following steps: a positioning seat 2 that can be adjusted is arranged on a guide rail 1 of the base to support and position the camshaft 3, and the other end of the guide rail 1 is arranged On the sliding seat 4 , a boss 6 supporting the flywheel pair 5 is arranged on the sliding seat 4 , and the sliding seat 4 is pushed to the positioning seat 2 so that the flywheel pair 5 on the boss 6 is sleeved on the end of the camshaft 3 . In the method for assembling the camshaft flywheel pair of the engine, the camshaft 3 is placed on the positioning seat 2 for horizon...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap