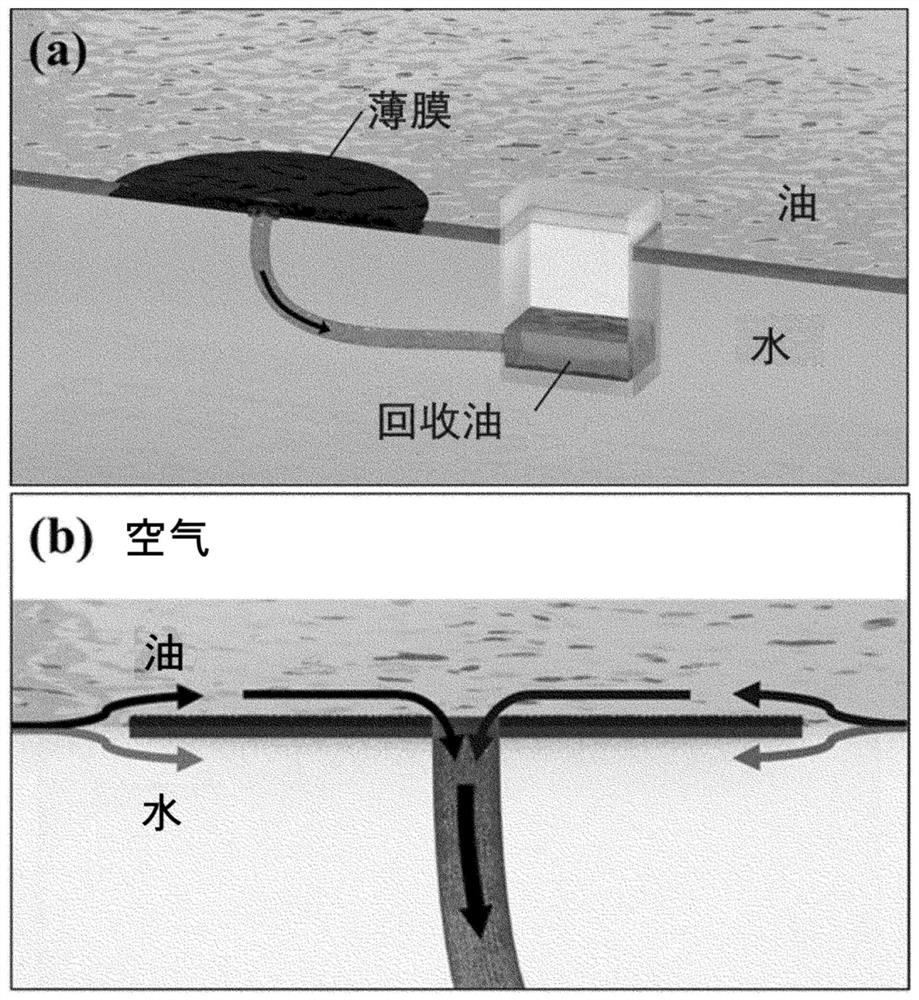

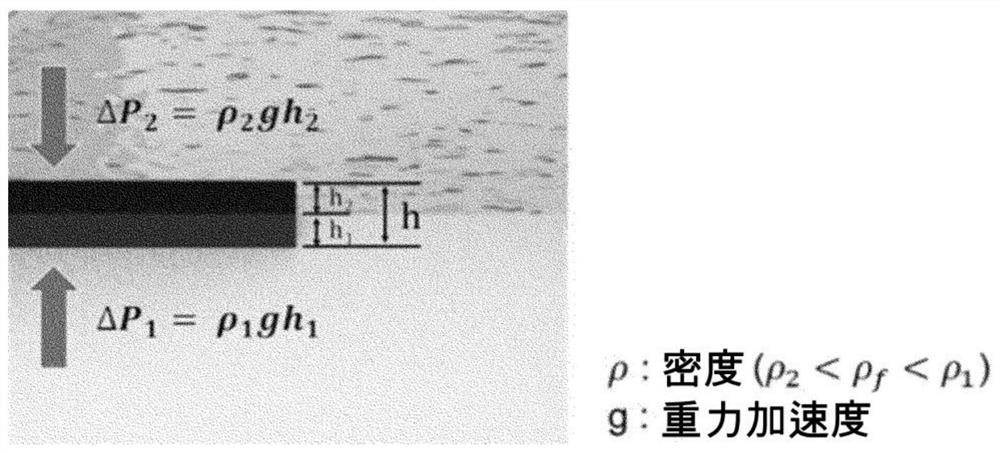

Water-oil separation device

An oil separation and oil recovery technology, applied in separation methods, liquid separation, water conservancy projects, etc., can solve problems such as high failure frequency, complex equipment, and difficulty in recovering oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0092] Hereinafter, the present invention will be described in more detail through examples. These examples are only for illustrating the present invention, and should not be construed as obvious to those skilled in the art that the scope of the present invention is limited by these examples.

manufacture example

[0093] Production example: Production of rGO / LDPE film

[0094] Low-density polyethylene (LDPE 963, Hanwha Chemical) was added to toluene (Toluene) in an amount of 5% by weight, and then heated at a temperature of 90° C. for 2 hours to dissolve the low-density polyethylene in toluene.

[0095]Graphene oxide (N002-PDE, ANGSTRON MATERIALS) powder was heat-treated at a temperature of 220 °C for 5 hours to obtain reduced graphene oxide (rGO) powder. The reduced graphene oxide powder was added to toluene in an amount of 1 mg / ml, and then subjected to sonication to uniformly disperse it.

[0096] A low-density polyethylene (LDPE) solution and a reduced graphene oxide solution were mixed so that the weight of rGO relative to LDPE became 0, 0.5, 1, 5, and 10% by weight, respectively.

[0097] The mixed solution was slowly poured into methanol to obtain composite particles of particle agglomeration.

[0098] After taking out 1.000 ± 0.010 g of the obtained reduced graphene oxide / low-...

experiment example 1

[0105] Experimental example 1: Measuring the physical properties of rGO / LDPE film

[0106] The physical properties of the rGO / LDPE film produced in the production example were analyzed according to the following items.

[0107] 1-1. Shape of film

[0108] In the above-mentioned manufacturing examples, the profiles of the LDPE film with the rGO content of 0% by weight and the rGO / LDPE film with 1% by weight were compared, and the Figure 8 shown in .

[0109] It was confirmed that the thin film made of only LDPE was a white translucent circular thin film, but the rGO / LDPE composite thin film was a black round thin film.

[0110] 1-2. Floating properties of thin film

[0111] To confirm the flotation properties of rGO / LDPE films, the 1% by weight rGO / LDPE films were added into a beaker with water and oil, then, Figure 9 The position of the film over time (a)->b)->c)) is shown.

[0112] It was confirmed that the rGO / LDPE film did not float on the oil but slowly sank, and wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com