Multi-purpose lossless quick mounting and dismounting edge protection net

A border protection, multi-purpose technology, applied in the direction of construction, building structure, building materials, etc., can solve the problems of blow damage, failure to stop falling, time-consuming and labor-intensive drilling and placement of expansion screws, etc., to prevent objects from hitting Injury, elimination of high falls, safety protection and the effect of synchronizing construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

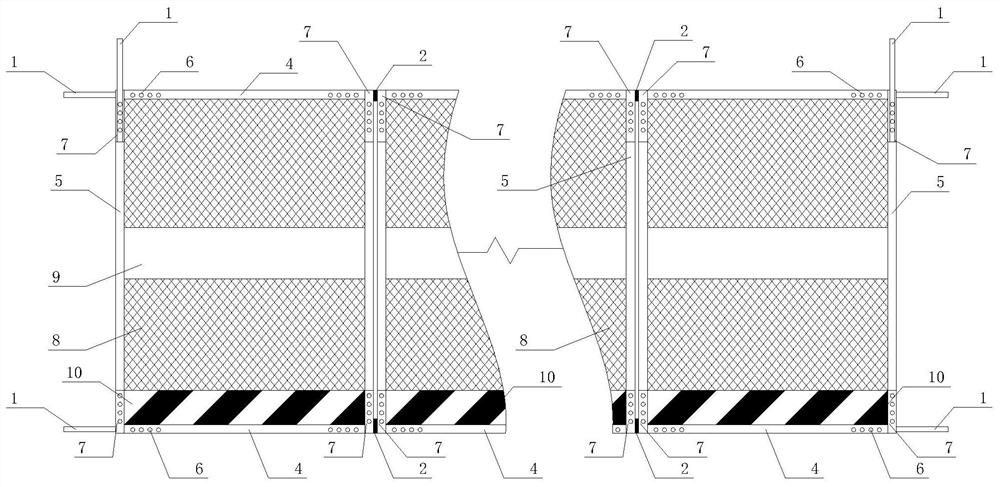

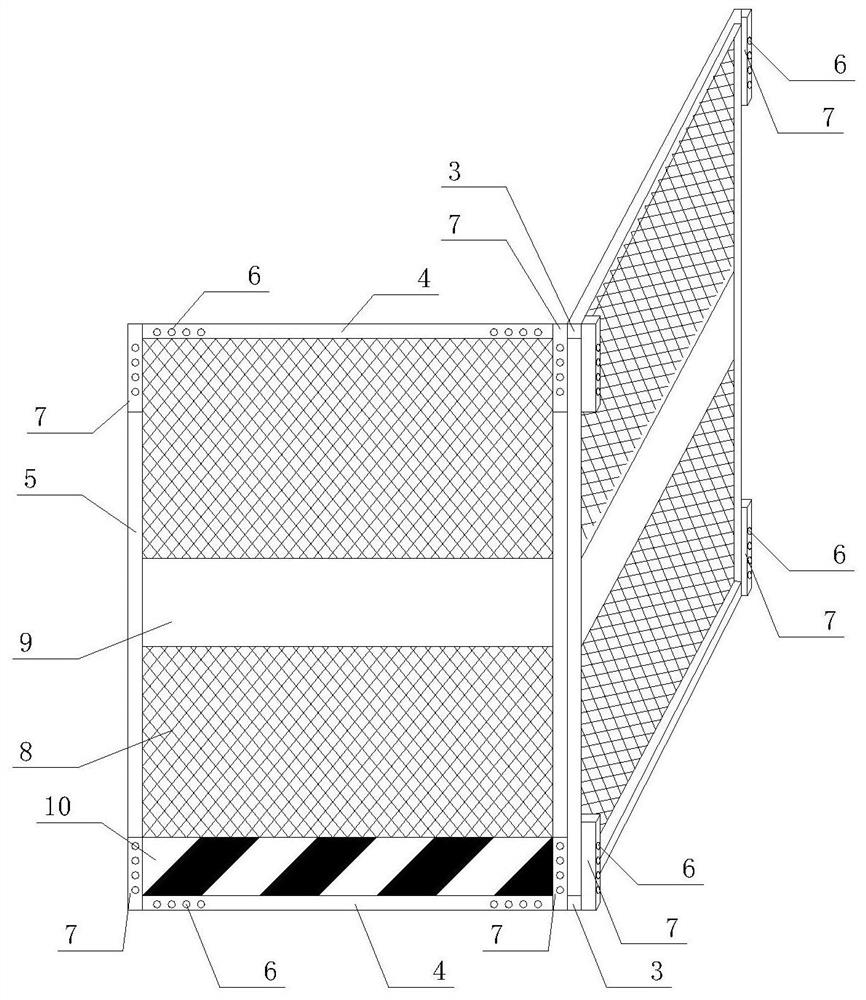

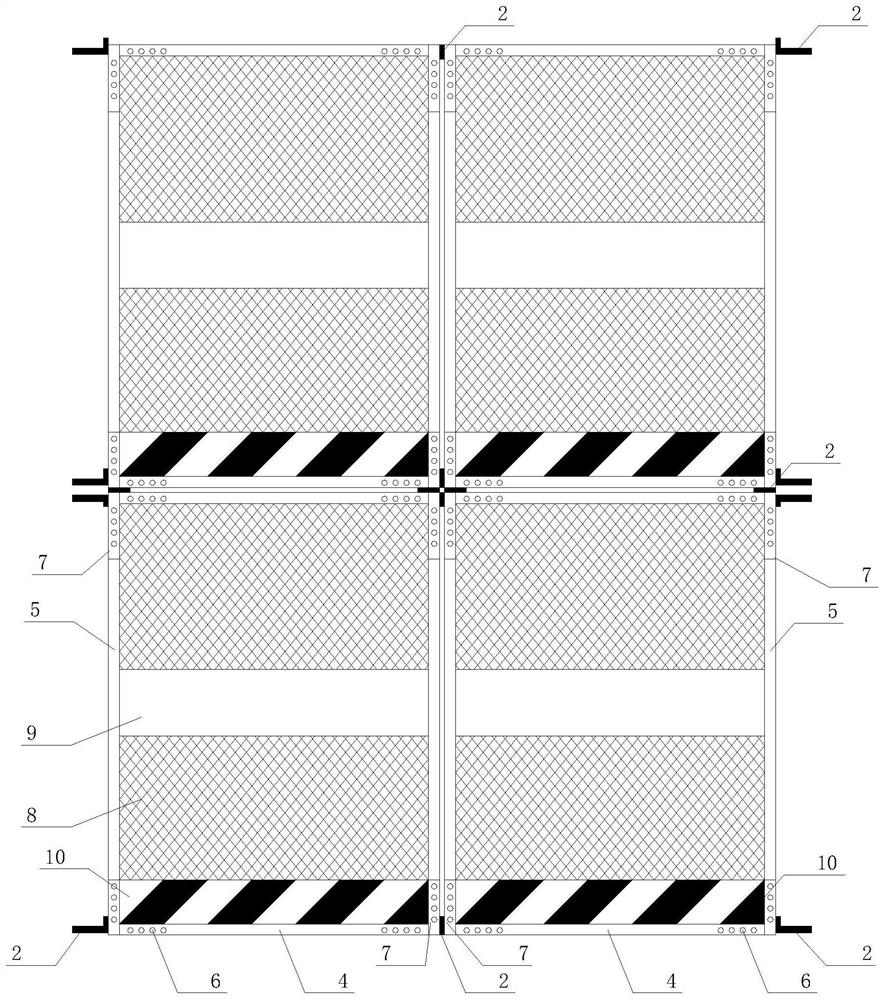

[0034] From figure 1 It can be seen that a multi-purpose non-destructive rapid installation and disassembly of the edge protection net in this embodiment includes a hollow horizontal square steel pipe 4 with holes, a hollow vertical square steel pipe 5 with holes, a short square steel pipe with holes 7 and a steel wire mesh 8. The hollow horizontal square steel pipe 4 with holes and the hollow vertical square steel pipe 5 with holes are welded to each other to form a square frame structure, and the short square steel pipes with holes 7 are vertically welded on the square steel pipe frame that has been welded respectively, and the internal welding of the square frame structure A steel wire mesh 8 is provided, the hollow horizontal square steel pipe 4 with holes, the hollow vertical square steel pipe 5 with holes, the short square steel pipe 7 with holes and the steel wire mesh 8 together form a protective net structure, and the adjacent protective net structures are connected by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com