A factory automatic sealing equipment

An automatic, factory technology, applied in packaging sealing/fastening, transportation packaging, packaging, etc., can solve the problems of labor consumption, long time, low sealing efficiency, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] A factory automatic sealing equipment, such as figure 1 As shown, it includes a bottom plate 1, a box sealing frame 2, a first support rod 3, a second support rod 4 and a push mechanism 5, the top rear side of the bottom plate 1 is provided with a box sealing frame 2, and the top rear side of the bottom plate 1 is symmetrically provided with a third A support rod 3 , a second support rod 4 is connected between the upper parts of the two first support rods 3 , and a push mechanism 5 is installed on the bottom plate 1 .

[0059] First, the worker puts the carton on the bottom plate 1, the worker holds the push mechanism 5, then the worker pushes the push mechanism 5 to slide backward, the push mechanism 5 is compressed, and when the push mechanism 5 contacts the carton on the bottom plate 1, the push mechanism 5 will push When the carton moves backward, when the carton is in contact with the carton sealing frame 2, the carton sealing frame 2 will seal the three sides of t...

Embodiment 2

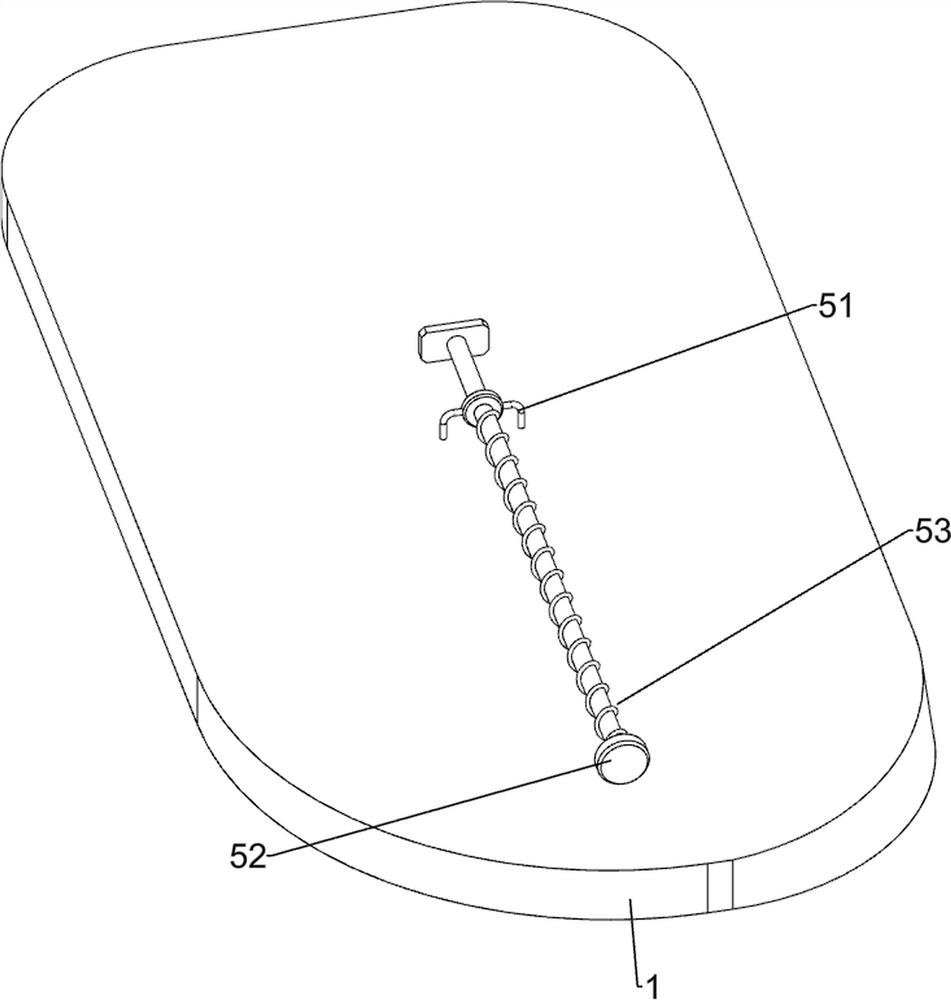

[0061] In a preferred embodiment of the present invention, as figure 2As shown, the push mechanism 5 includes a third support rod 51, a pusher 52 and a first spring 53, a third support rod 51 is provided in the middle of the top of the bottom plate 1, and a pusher 52 is slidably provided on the upper part of the third support rod 51 to push A first spring 53 is sleeved on the device 52 , and both ends of the first spring 53 are respectively connected to the third support rod 51 and the pusher 52 .

[0062] First, the worker puts the carton on the bottom plate 1, the worker holds the pusher 52, then the worker pushes the pusher 52 to slide backward on the third support rod 51, the first spring 53 is compressed, and the pusher 52 and the carton on the bottom plate 1 When in contact, the pusher 52 slides backwards to push the carton to slide backwards. When the carton is in contact with the sealing frame 2, the sealing frame 2 seals the three sides of the carton in contact, and ...

Embodiment 3

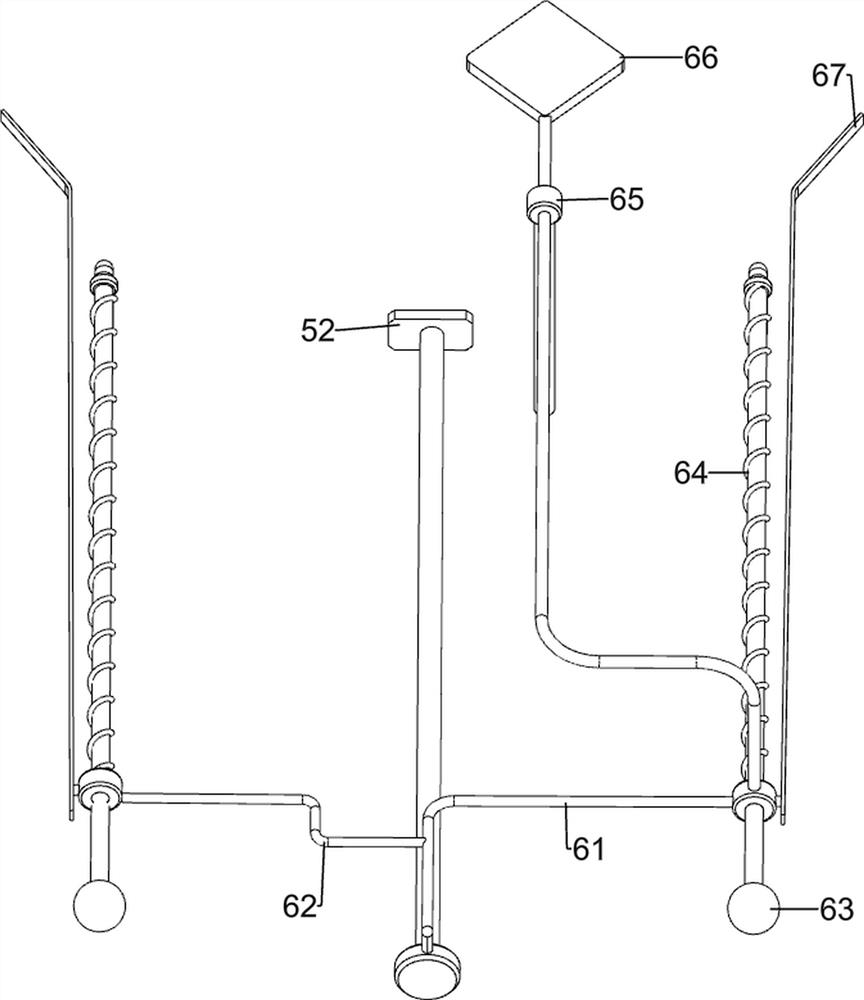

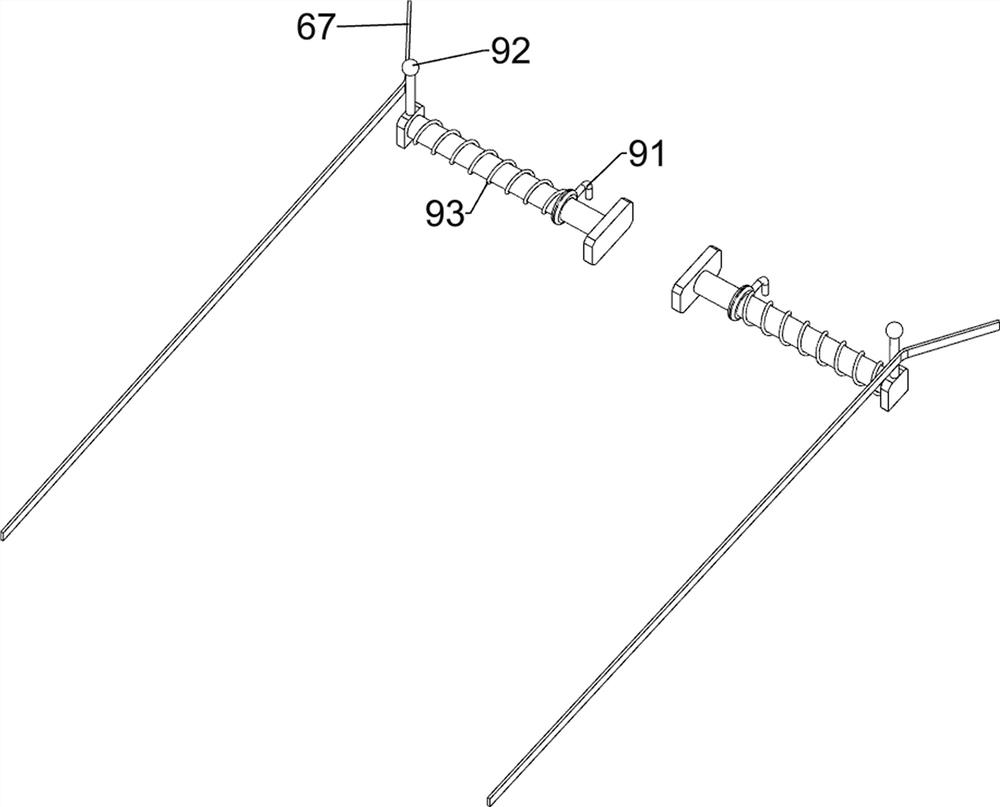

[0064] In a preferred embodiment of the present invention, as figure 1 and Figure 2-Figure 7 As shown, it also includes a first auxiliary mechanism 6, and the first auxiliary mechanism 6 includes a first connecting rod 61, a second connecting rod 62, a fourth supporting rod 63, a second spring 64, a fifth supporting rod 65, a wedge-shaped block 66 and convex plate 67, the front part of the pusher 52 is provided with a first connecting rod 61, the upper left side of the first connecting rod 61 is provided with a second connecting rod 62, the left and right sides of the bottom plate 1 are provided with a fourth supporting rod 63, The outer sides of the first connecting rod 61 and the second connecting rod 62 are both slidably connected to the fourth support rod 63 , the two fourth support rods 63 are sleeved with second springs 64 , and the two ends of the second spring 64 on the right side are respectively connected On the first connecting rod 61 and the fourth supporting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com