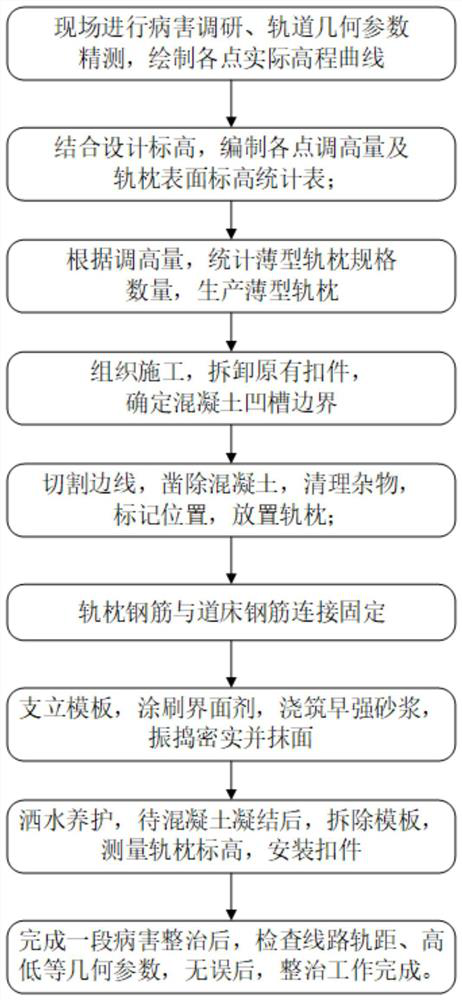

Failure renovation method suitable for sleeper-free ballast bed directly-buried base plate

A technology of track bed and direct burial, applied in the directions of roads, tracks, ballast layers, etc., can solve the problems of difficult to meet the remediation needs of the existing lines, difficult construction, and long construction period, so as to shorten the disease remediation period and improve the connection. The effect of stability and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

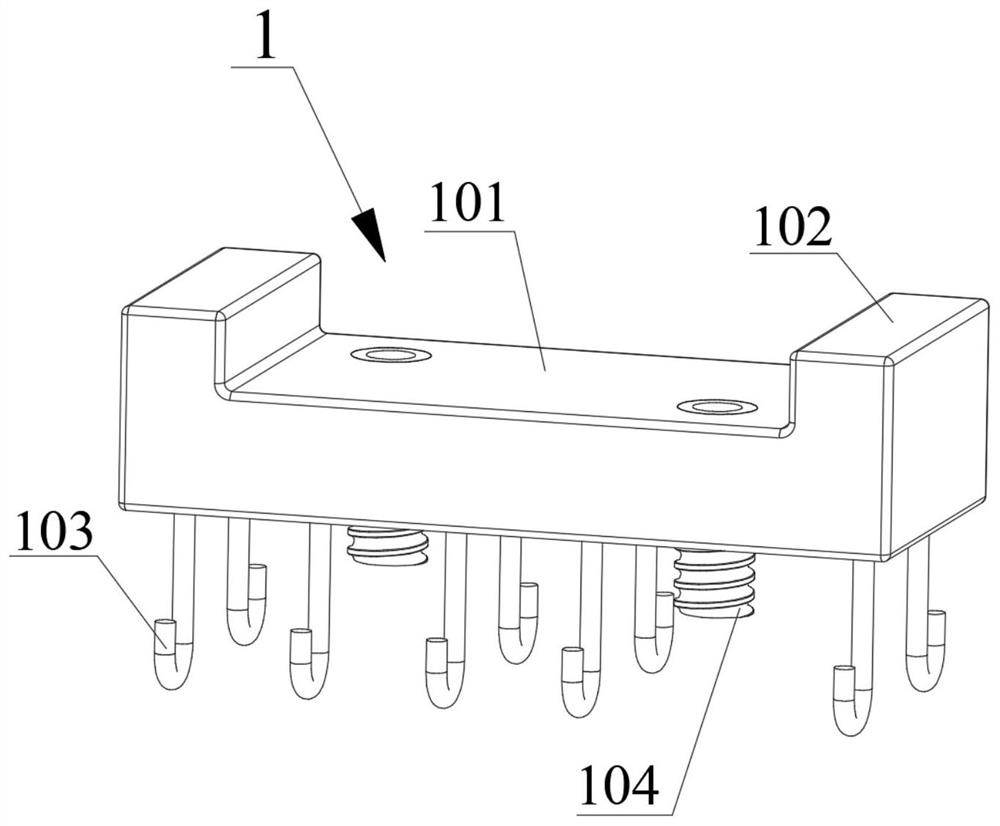

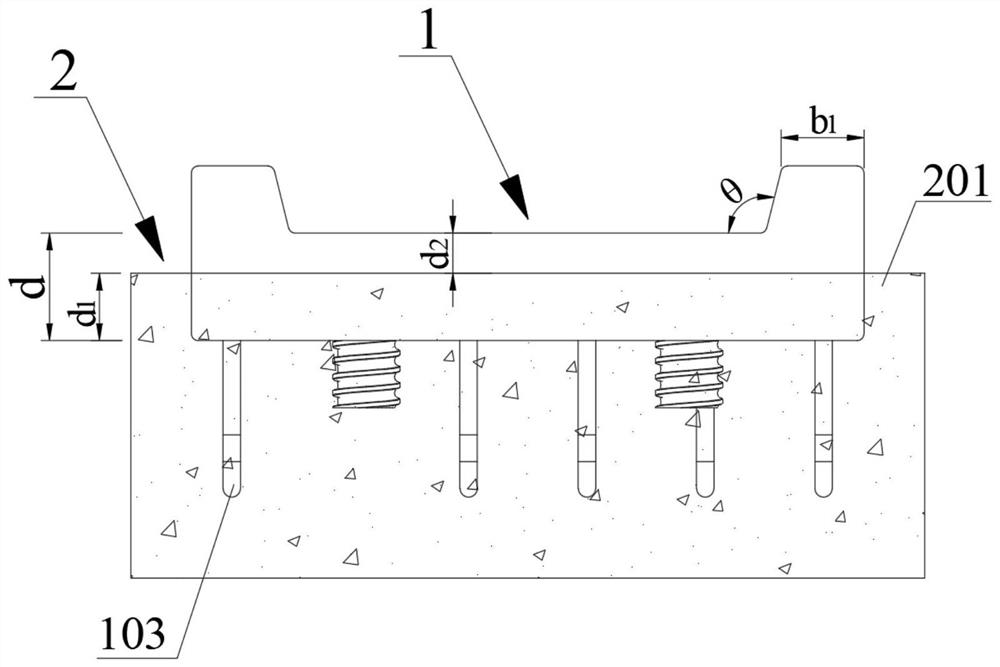

[0047] see Figure 2-5 In the preferred embodiment of the present invention, the failure rectification method applicable to the directly buried backing plate of the pillowless ballast bed is realized by using the thin sleeper 1 with block structure. In a preferred embodiment, the thin sleeper 1 includes a sleeper main body 101 of a block structure, and sleeper shoulders 102 are respectively arranged on both sides of the top surface of the sleeper main body 101, so that the rail 3 can be fixed on both sides by the fastener 4 when it is set. Between the sleeper shoulders 102.

[0048] Specifically, the thin sleeper 1 in the preferred embodiment is intended to ensure the fixed strength of the rail 3 without cutting off the ballast bed steel bar 202 in the failure rectification position of the pillowless ballast bed direct buried backing plate 2 . In actual installation, the sleeper main body 101 includes an embedding part and a height adjustment part arranged vertically in seque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com