Anti-wrinkle machining method for aluminum alloy bent pipe fitting

A processing method and technology of aluminum alloy, applied in the field of aluminum alloy parts processing, can solve problems such as affecting product quality and folds at bending, and achieve the effect of reducing irregular deformation and folds, and achieving good control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: An anti-wrinkle processing method for aluminum alloy bending pipe fittings, including S1, installation and positioning, clamping the aluminum alloy pipe fittings horizontally; S2, piercing the inner liner 6, and penetrating the outer diameter of the aluminum alloy pipe fittings The inner diameter of the rubber lining tube 6 is the same as that of the aluminum alloy pipe fitting to be bent, and the end of the lining pipe 6 needs to pass through the bending position; Dynamic bending until the complete bending angle reaches 90 degrees; S4, pipe cutting, using cutting equipment to cut off the bending part of the pipe.

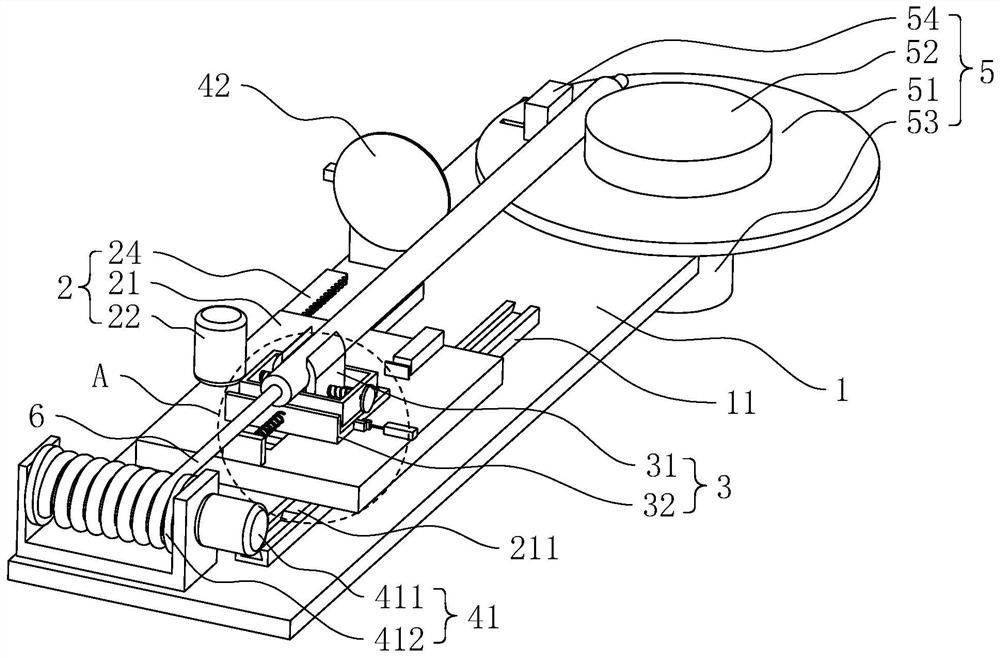

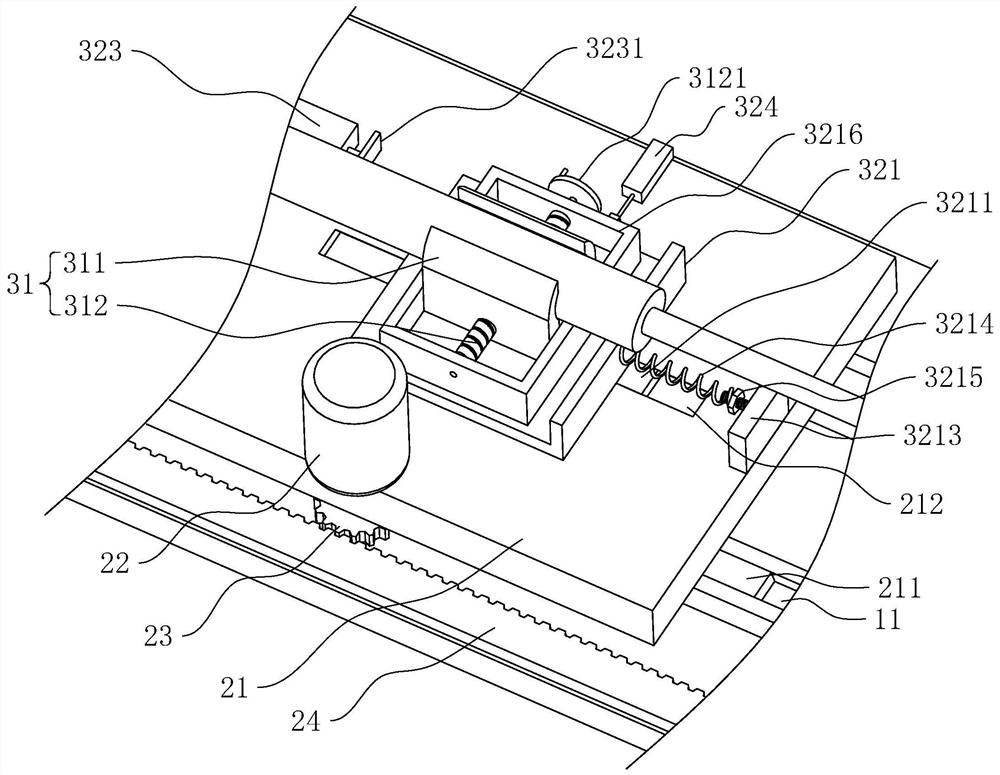

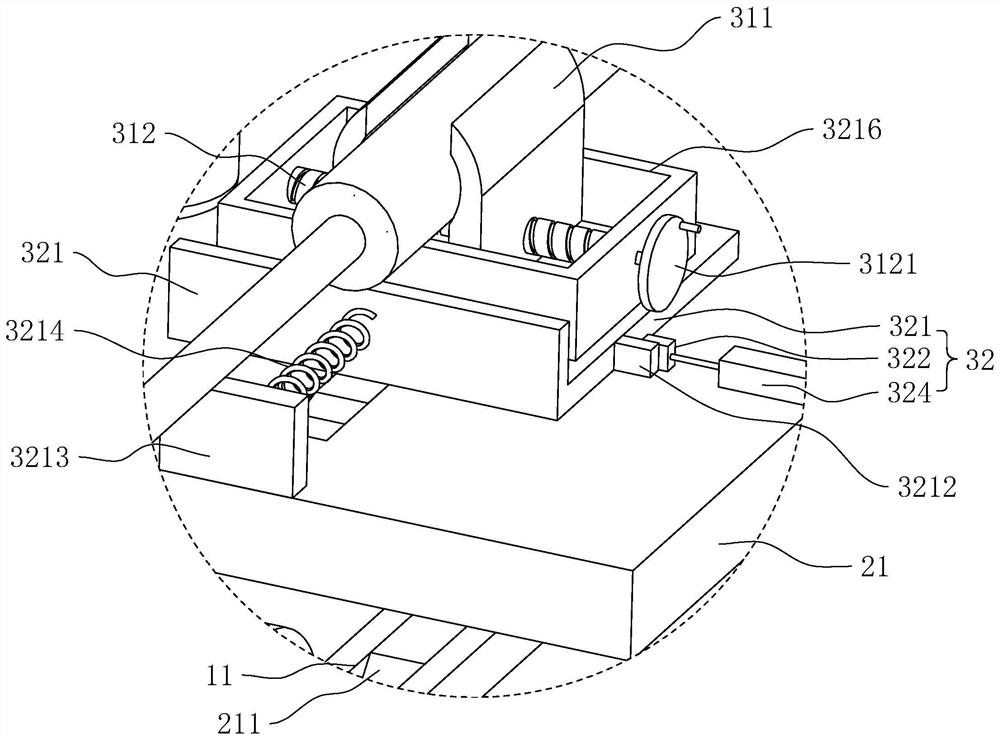

[0038] Among them, such as figure 1 As shown, the bending machine specifically includes a workbench 1 and a conveying device 2 , a clamping device 3 , a cutting device and a bending device 5 sequentially arranged on the workbench 1 .

[0039] Such as figure 1As shown, the workbench 1 is placed on the ground, and the conveying device 2 include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com