Nested tool magazine of numerical control machine tool

A CNC machine tool, nested technology, applied in metal processing mechanical parts, clamping, support and other directions, can solve the problems of changing the loading and unloading position, high cost, inability to adapt to the manipulator, and achieve the effect of expansion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

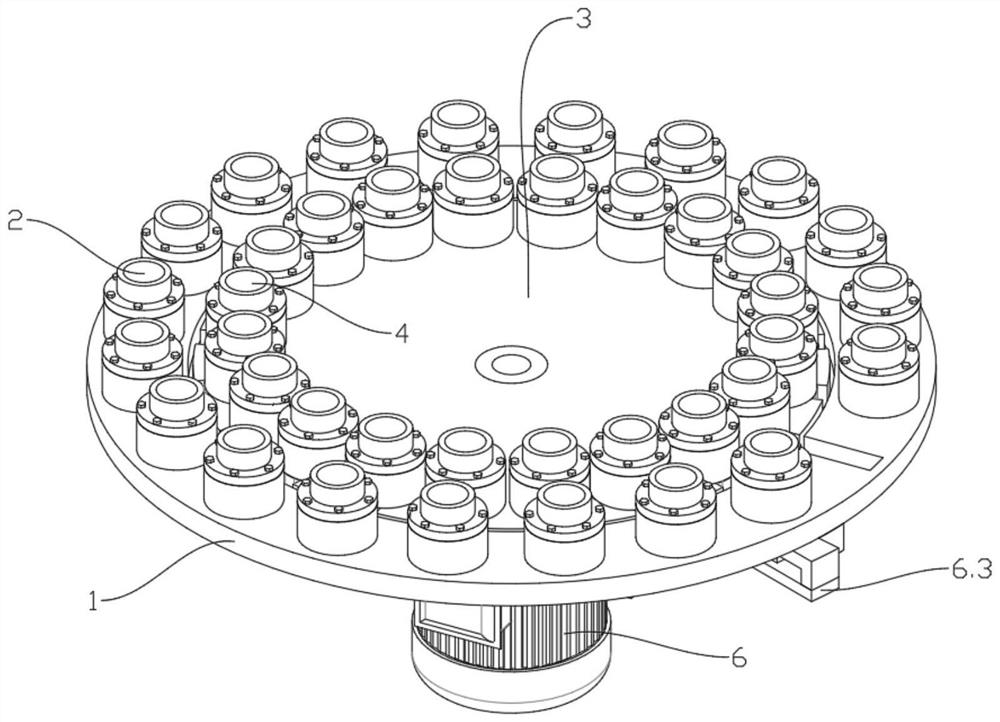

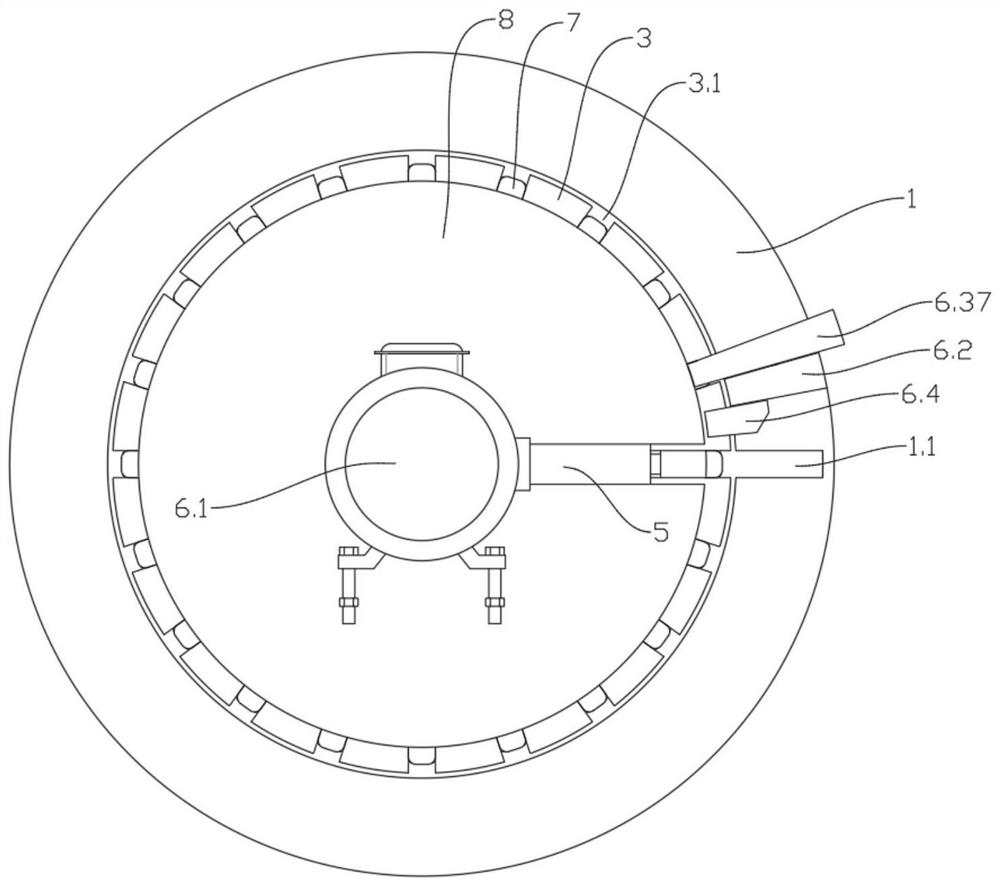

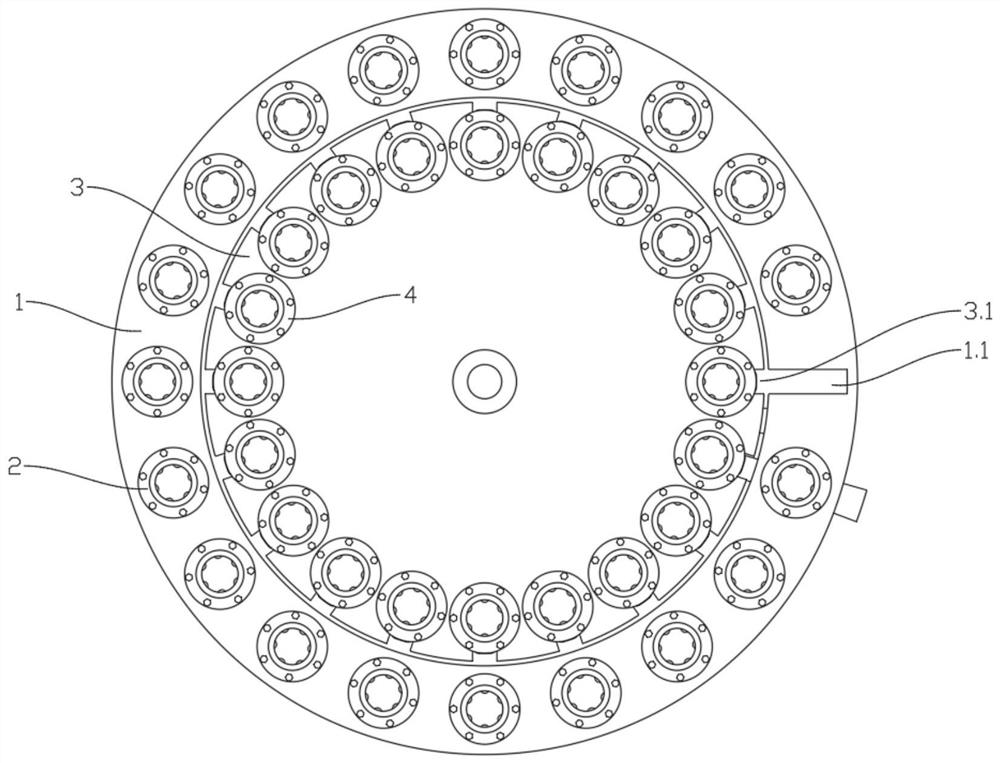

[0031] see Figure 1-10 A nested tool magazine for a numerically controlled machine tool provided by an embodiment of the present invention includes an outer cutterhead 1 and an inner cutterhead 3, and a plurality of first tool clamping mechanisms 2 are arranged in a circular distribution on the outer cutterhead 1, The outer cutterhead 1 has a loading and unloading position. By rotating the outer cutterhead 1 so that any first tool clamping mechanism 2 on it reaches the loading and unloading position, there is at least one avoidance space on the outer cutterhead 1; the inner cutterhead 3 is distributed in a ring A plurality of second tool clamping mechanisms 4 are arranged, and each second tool clamping mechanism 4 can slide along the radial dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com