Chassis and AGV trolley

A chassis and trolley technology, applied in vehicle maintenance, lifting vehicle accessories, transportation and packaging, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

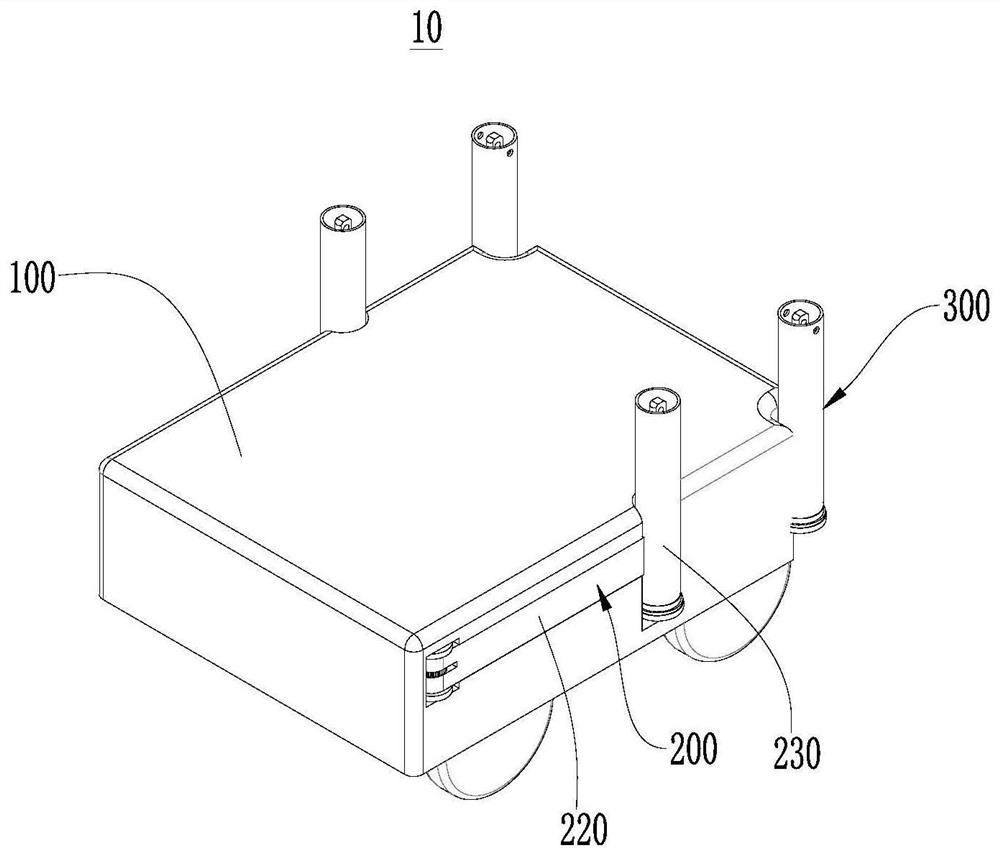

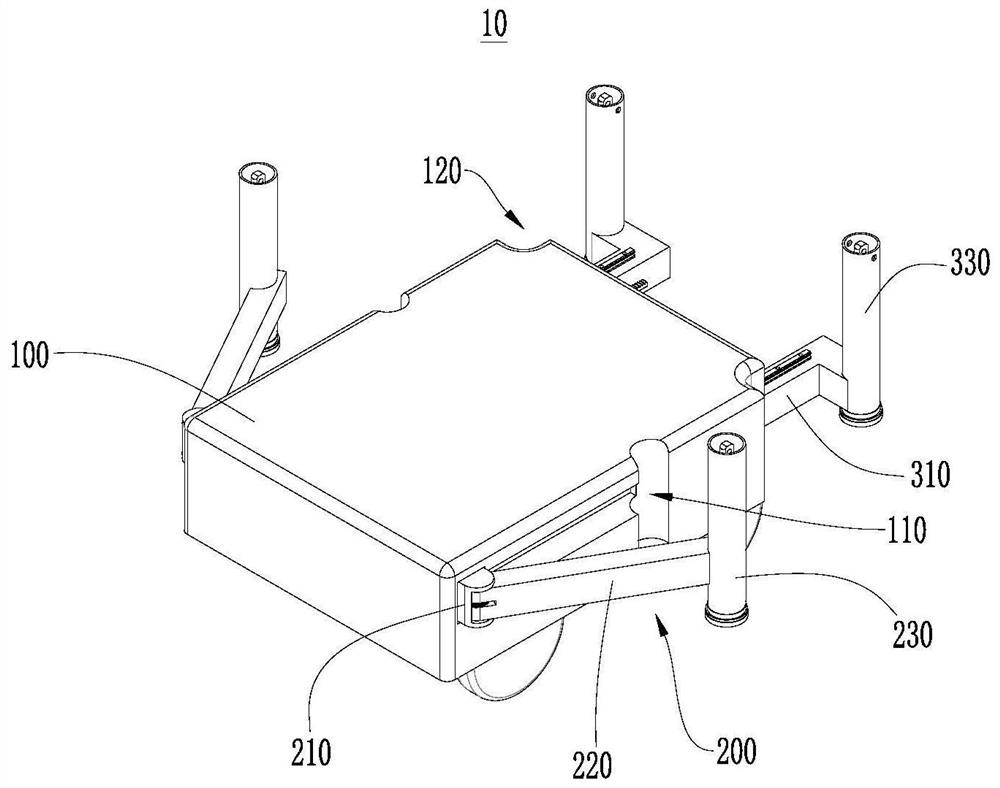

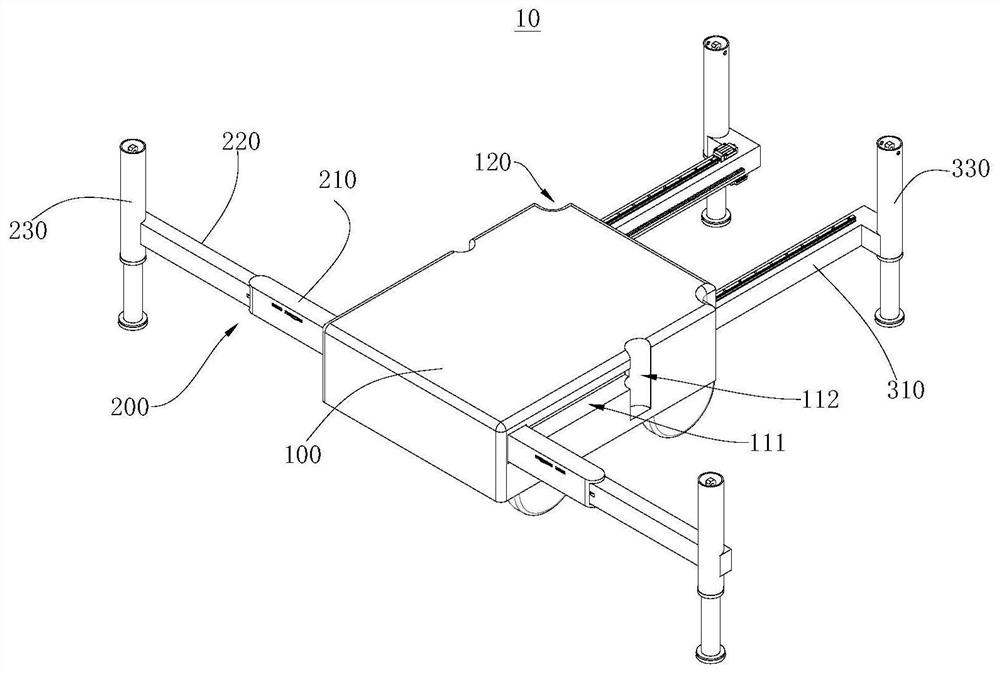

[0030] Please refer to figure 1 , with reference to image 3 , Figure 4 and Figure 5, the present embodiment provides a chassis 10 , and the chassis 10 includes a chassis body 100 , a first leg 200 and a first driving mechanism 500 . The first leg 200 includes a front arm 210 and a rear arm 220 , the front arm 210 is connected to the chassis body 100 , and the rear arm 220 is connected to the front arm 210 . The first driving mechanism 500 is used to drive the first leg 200 to expand or retract. The first driving mechanism 500 can drive the rear arm 220 to move relative to the front arm 210 while driving the front arm 210 to move relative to the chassis body 100 . By providing the chassis body 100 , it is convenient to install the first leg 200 and the first driving mechanism 500 . A first driving mechanism 500 is provided to drive the first leg 200 , and the first driving mechanism 500 can drive the rear arm 220 to move relative to the front arm 210 while driving the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com