Method for treating polarizing plate manufacturing waste liquid

A processing method and polarizing plate technology, applied in the field of potassium iodide recovery, can solve problems such as insufficient quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

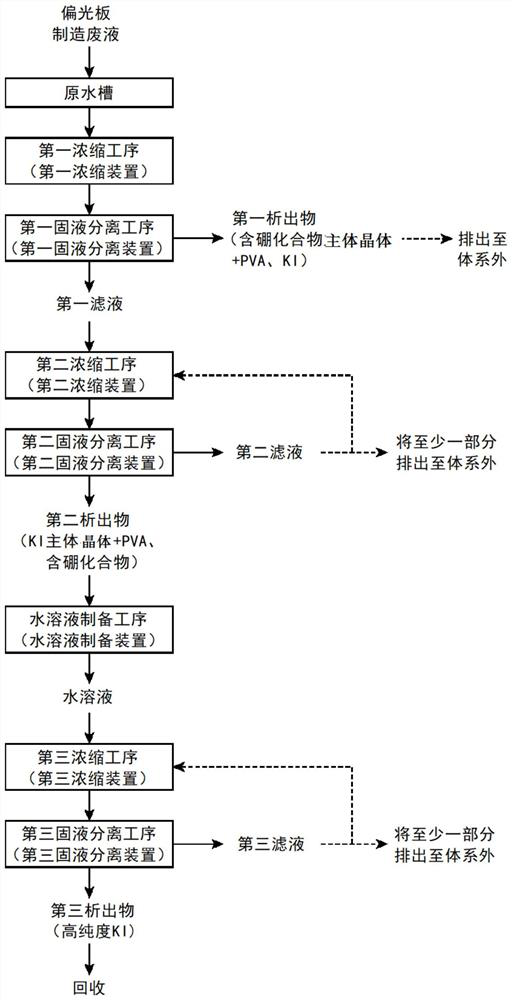

[0042]Actual manufacturing the polarizing plate polarizing plate manufacturing waste generated sequentially supplied to the first concentration step, a cooling crystallization step, the first solid-liquid separation step, a second concentration step, the second solid-liquid separation step, the aqueous solution preparation step, the third step is concentrated and a third solid-liquid separation step, a waste liquid recovery polarizing plate manufactured in KI.

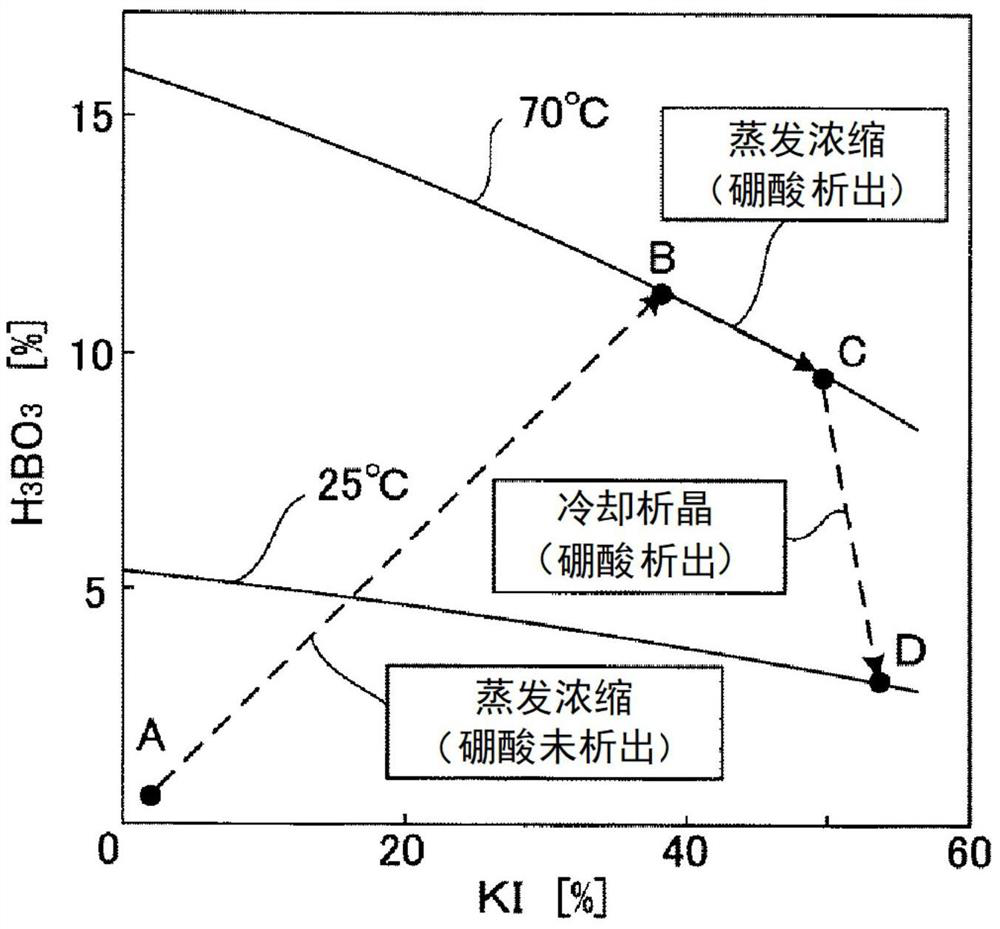

[0043] The first step was concentrated by means of the heat pump type configuration concentrated to the front portion (upstream), concentrated and flash-type apparatus disposed in the subsequent stage (downstream) is performed. In a first concentration step, while maintaining the temperature at 70 deg.] C while the waste is concentrated by evaporation producing the polarizing plate. By cooling crystallization step the temperature was cooled from 70 deg.] C to 25 deg.] C is performed. Generating a first precipitate by cooli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap