Lamplight device for curved glass detector

A curved glass and detection machine technology, which is applied in the direction of measuring devices, optical testing of flaws/defects, and material analysis through optical means, can solve problems such as insufficient lighting angles and paths, detection omissions, etc., to reduce omissions and solve omissions , Improve the effect of the lighting environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

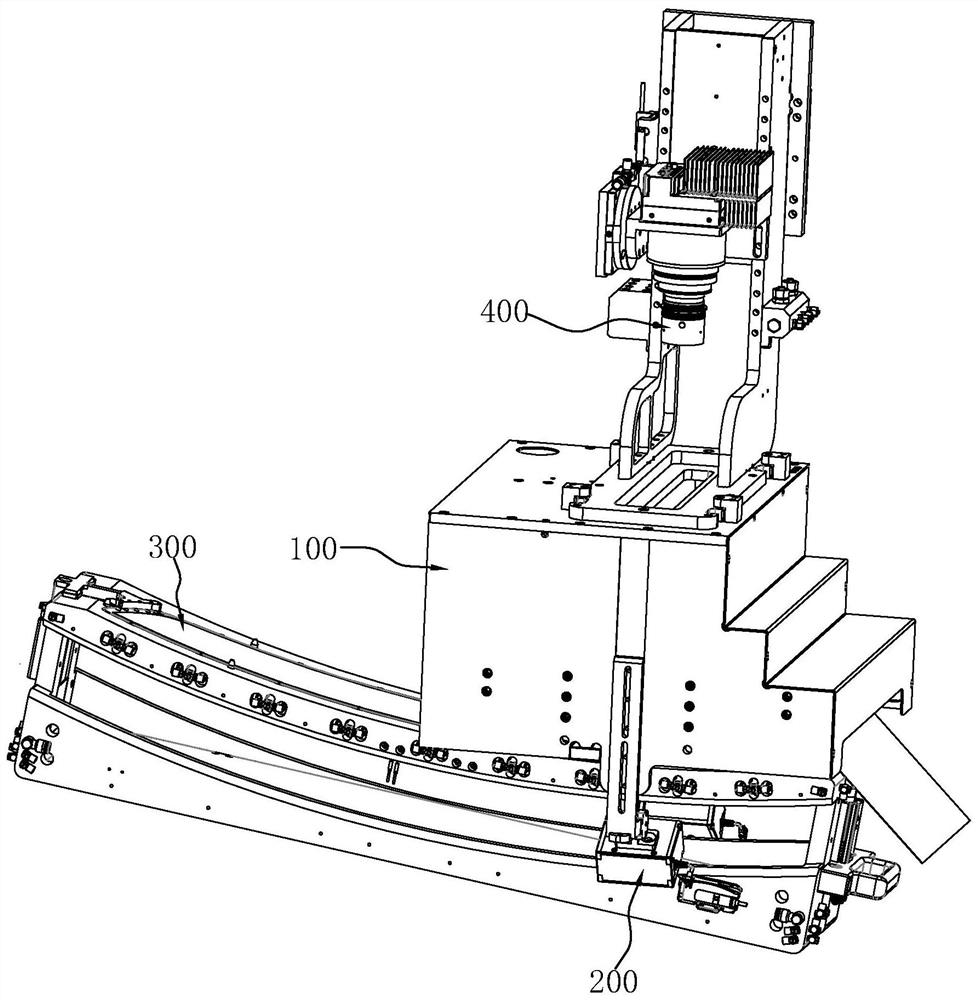

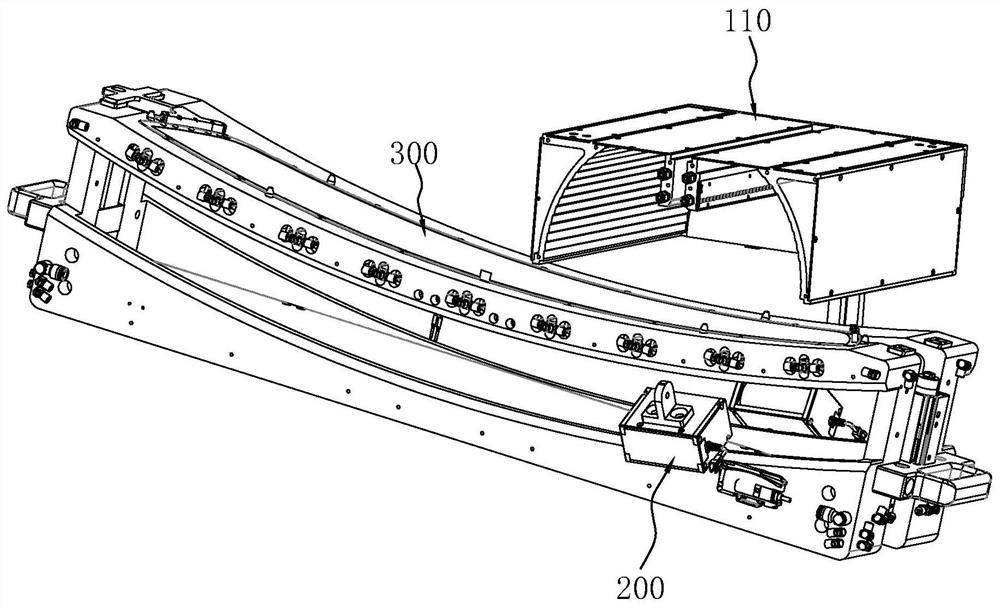

[0039] Please refer to Figure 1-Figure 5 , the invention discloses a lighting device for a curved glass inspection machine, comprising:

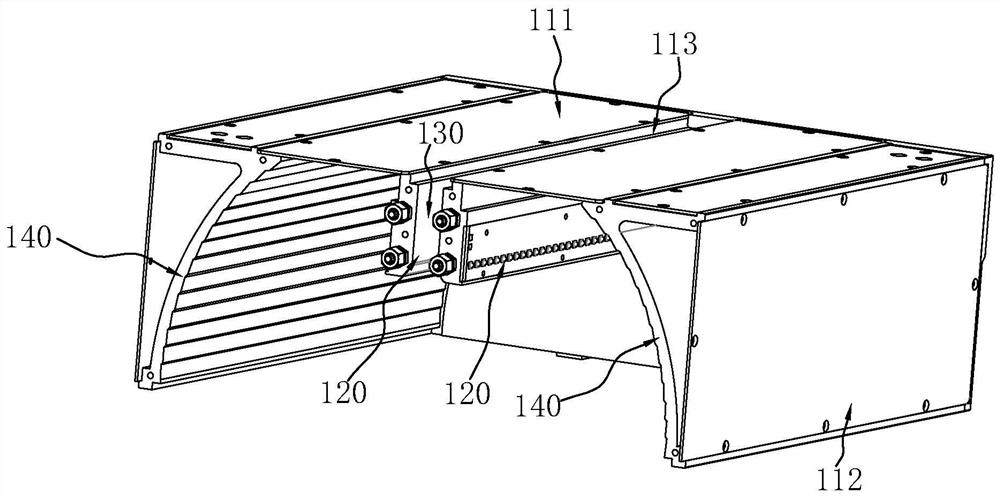

[0040] The first light source assembly 100 is arranged on one side of the curved glass 300. The first light source assembly 100 includes: at least one luminous body 120; at least one reflective plate 140, the reflective plate 140 has a plurality of reflective areas, multiple The reflective areas are arranged in an arc;

[0041] The second light source assembly 200 is disposed on a side of the curved glass 300 away from the first light source assembly 100 .

[0042] Specifically, in this embodiment, a first light source assembly 100 and a second light source assembly 200 are provided, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com