Composite floor structure

A technology for combining floor slabs and inserting panels, which is applied in the direction of floor slabs, building components, building structures, etc., can solve the problems of inconvenient disassembly and assembly of profiled steel plates, and achieve the effect of easy disassembly and assembly and easy reset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

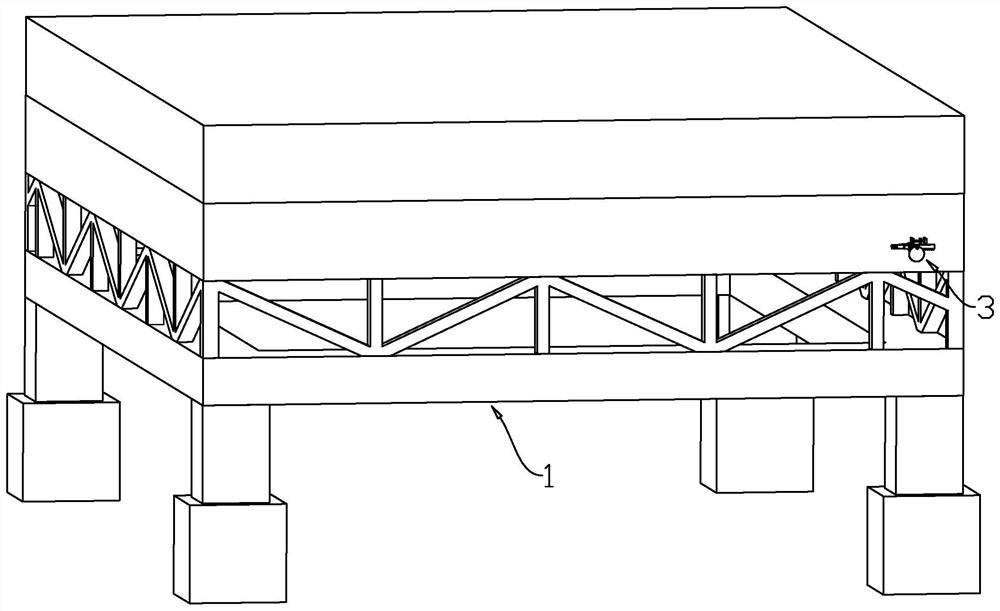

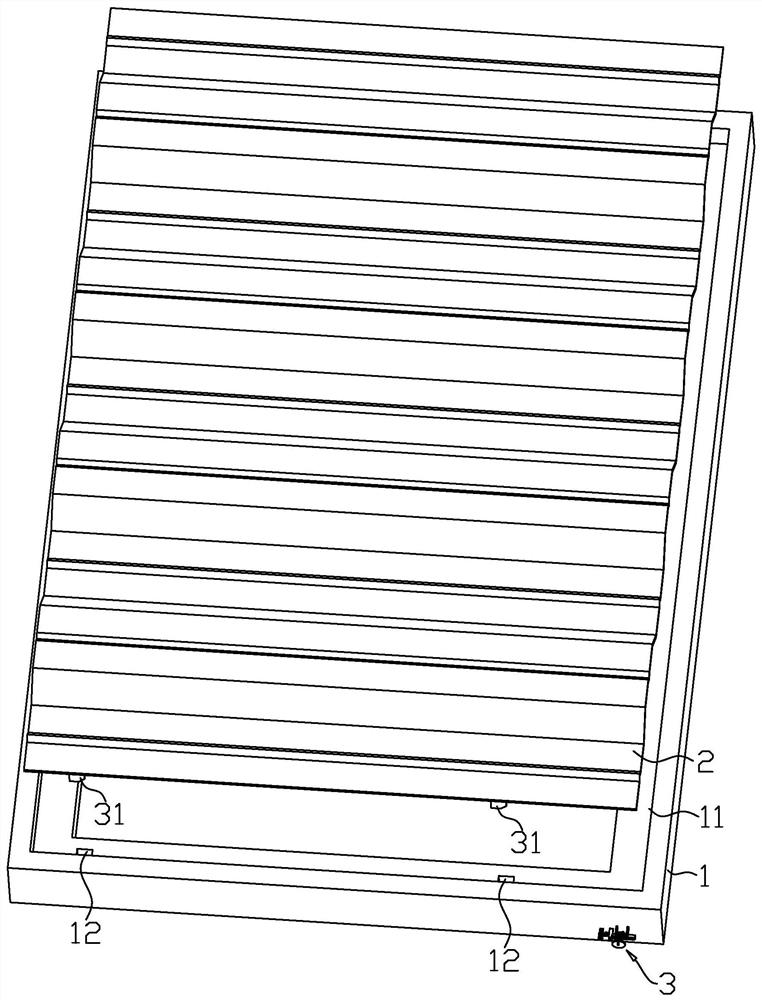

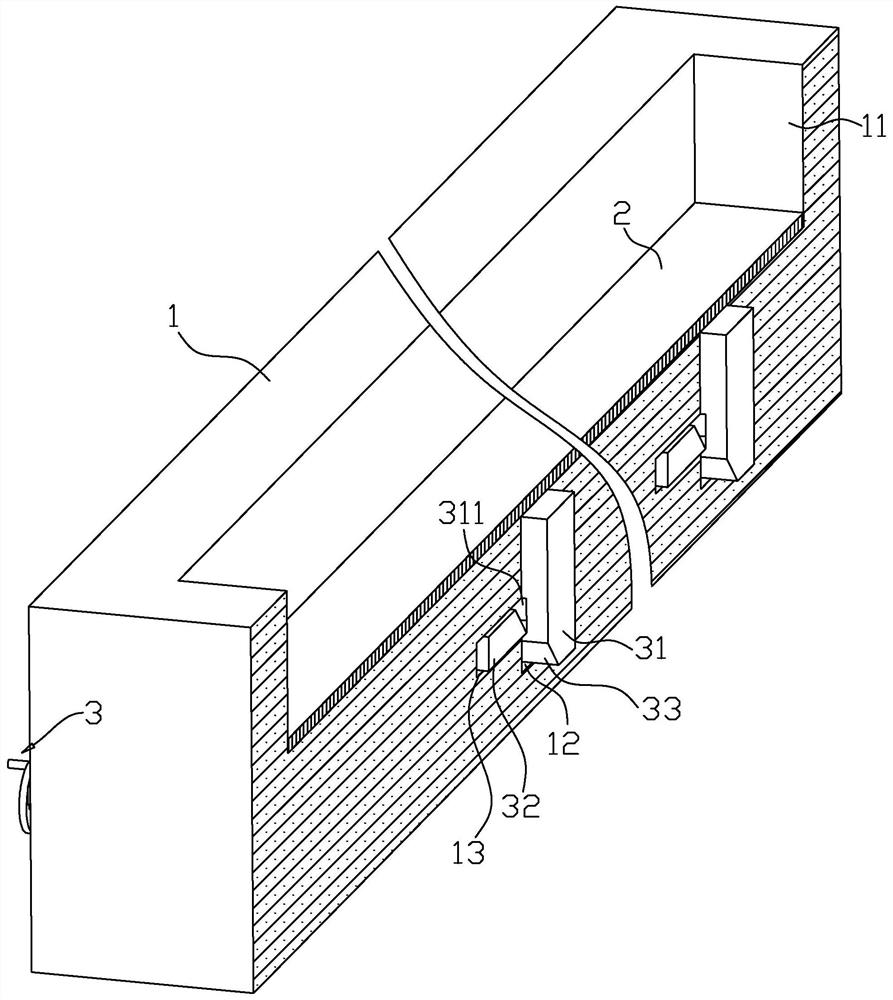

[0033] The invention discloses a composite floor structure, such as figure 1 and figure 2 As shown, it includes a truss girder 1, a profiled steel plate 2 installed on the top of the truss girder 1, and an upper plate installed on the top of the profiled steel plate 2. The top of the truss beam 1 is provided with a sinking groove 11 for placing the profiled steel plate 2. Fixing devices 3 for fixing the profiled steel plate 2 are installed at both ends of the groove 11 .

[0034] Such as figure 2 and image 3As shown, each set of fixing devices 3 includes a plurality of flashboards 31, and the flashboards 31 are vertically arranged, and one end of the sinker 11 is provided with a plurality of slots 12, and the slots 12 extend vertically, and the flashboards 31 correspond to each other one by one. Inserted in the slot 12, and the inserting plate 31 is vertically fixed on the bottom of the profiled steel plate 2, the inserting plate 31 is provided with a limiting groove 311...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap