Solenoid type inductor and manufacturing method thereof

A technology of inductors and solenoids, applied in the field of inductors, can solve the problems of inconvenient coil and magnetic core replacement, and achieve the effect of easy replacement and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

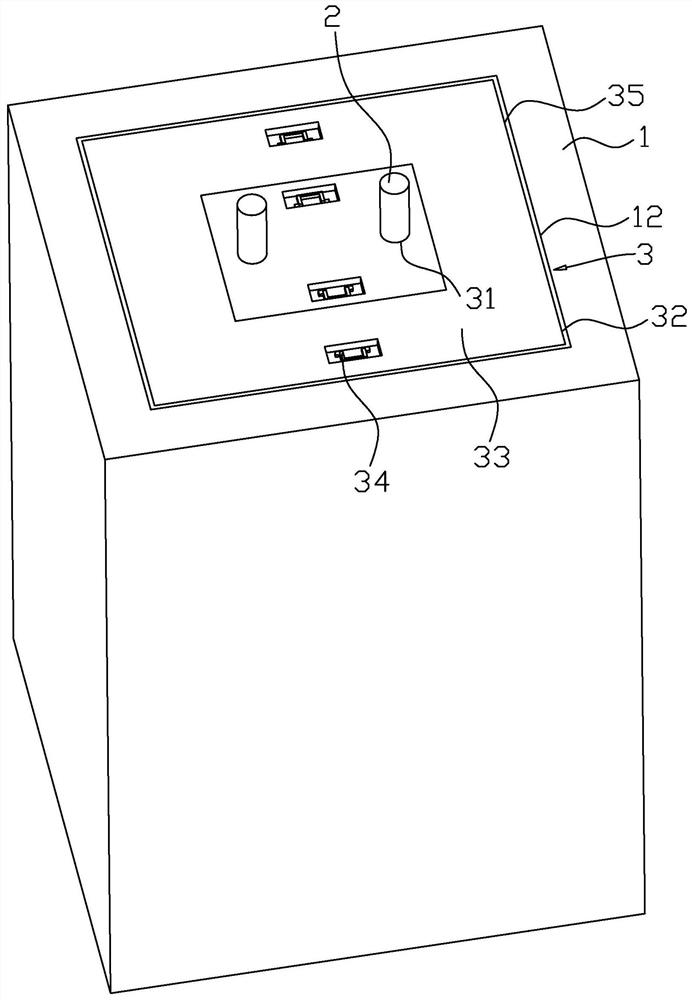

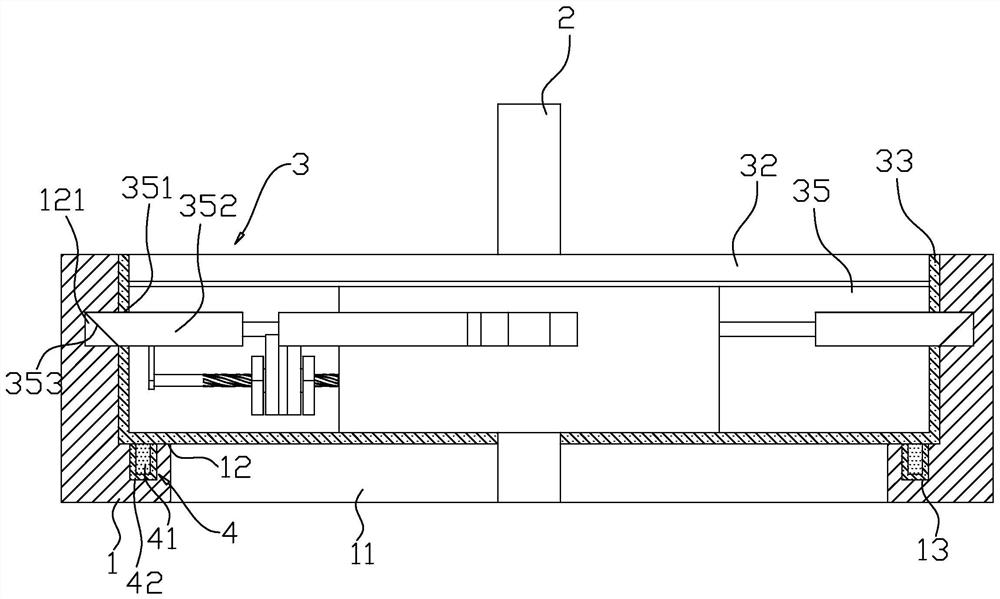

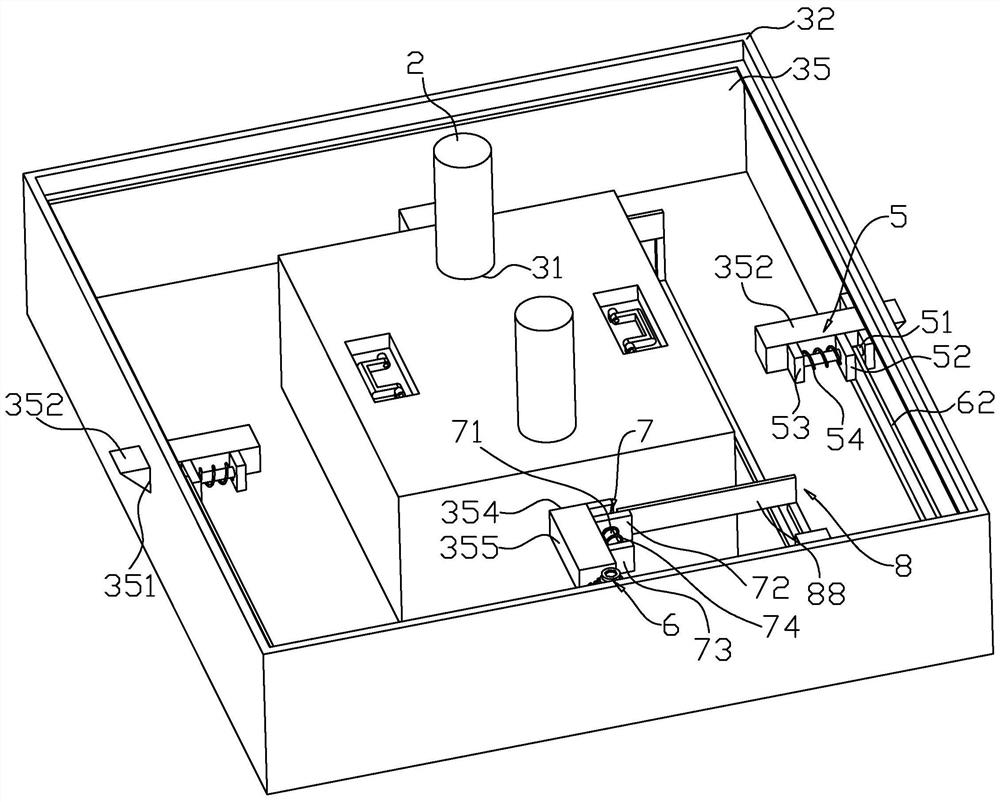

[0035] The invention discloses a solenoid inductor. The solenoid inductor in this embodiment is mainly suitable for large electrical equipment, such as figure 1 and figure 2 As shown, including a coil, a magnetic core, an insulating frame 1 and two pins 2, an insulating cover 3 is installed at the opening 11 of the insulating frame 1, the insulating cover 3 is square, and two through holes are opened on the insulating cover 3 31. The through hole 31 extends vertically. The insulating cover 3 includes a mounting block 32 and a cover plate 33 detachably connected to the mounting block 32. Both the mounting block 32 and the cover plate 33 are provided with a handle 34. The cover plate 33 can be passed through the bolt Or the buckle is connected with the installation block 32, the installation block 32 is square, and the ends of the two pins 2 away from the coil are respectively installed in the two through holes 31; the opening 11 of the insulating frame 1 is provided with a sin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap