Automobile trimming device

A hemming and automotive technology, applied in the mechanical field, can solve problems such as the inability to guarantee the stability of the driving parts, and achieve the effect of ensuring stability and driving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

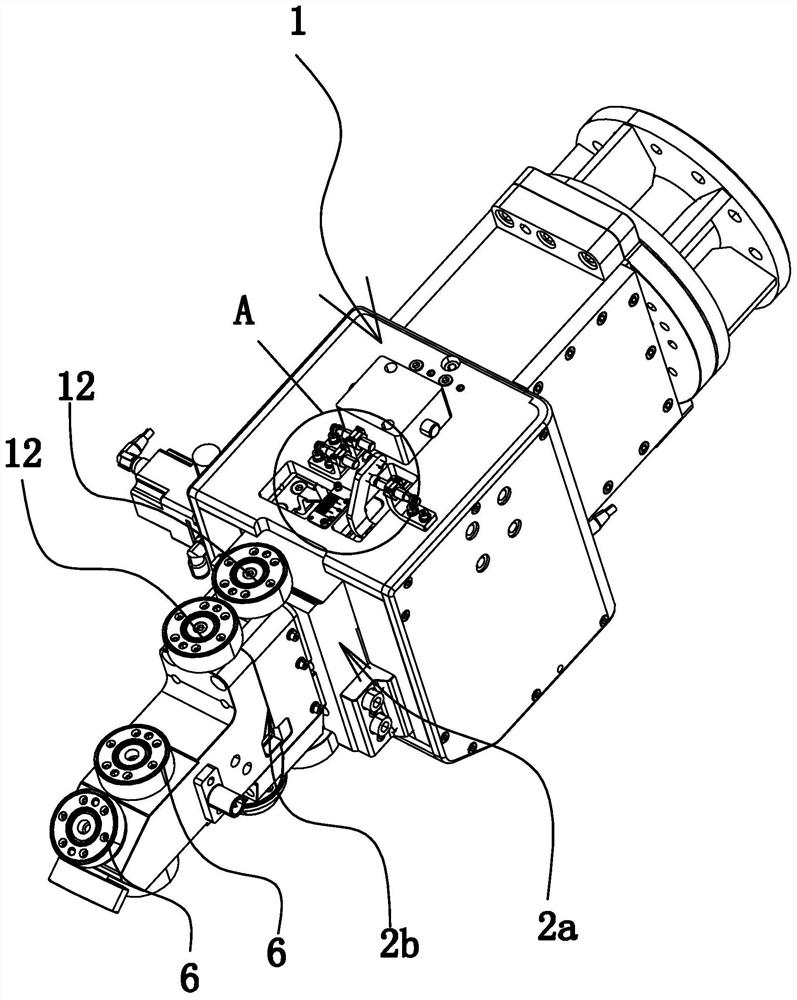

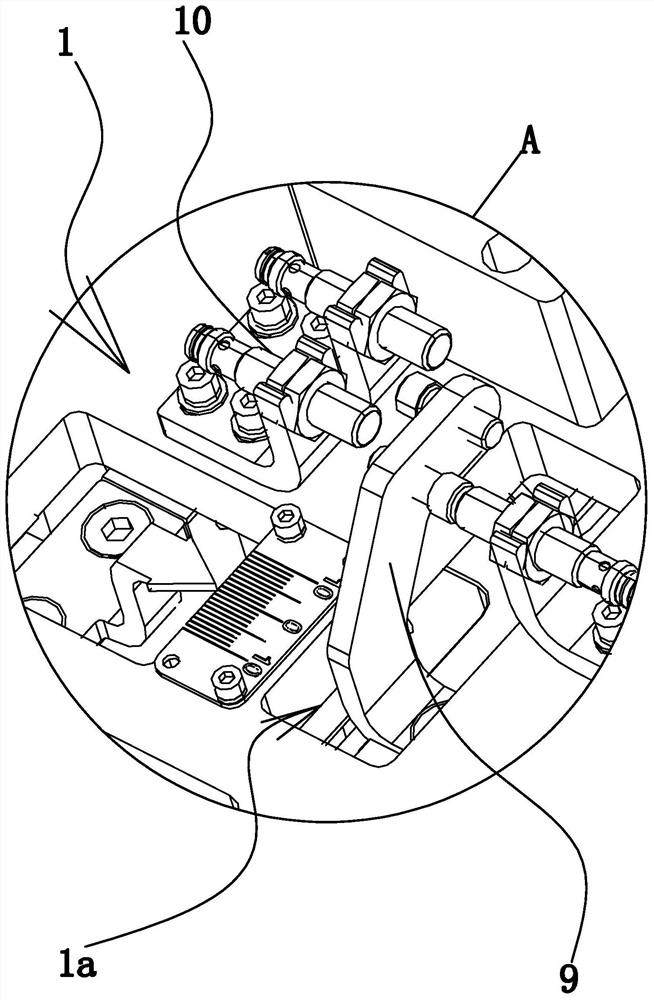

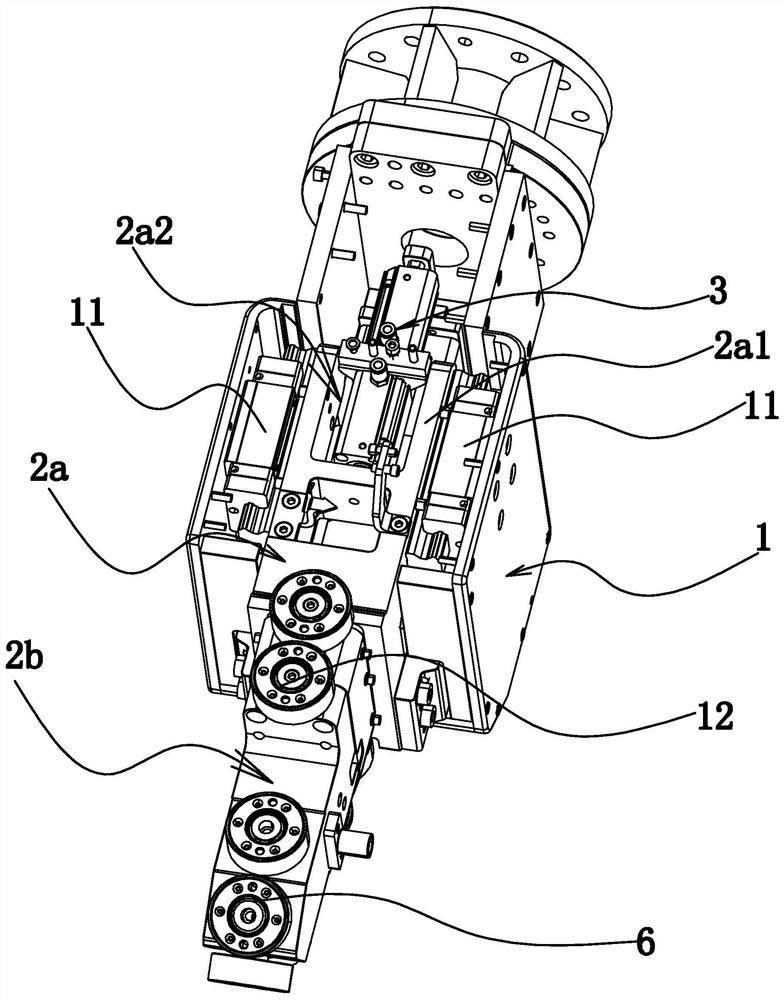

[0034] The car hemming device, such as image 3 , Figure 4 As shown, it includes a housing 1 and a hemming head 2 for sheet metal hemming. The hemming head 2 includes a block-shaped adjustment seat 2a and a working head 2b provided with several sets of hemming wheels 6. The sliding of the adjustment seat 2a is arranged on the shell In the body 1, the working head 2b is slidably arranged on the outer end of the adjustment seat 2a, and the adjustment seat 2a is slidably connected in the housing 1 through the guide rail assembly, and the driving member 3 capable of driving the hemming head 2 to slide is fixed in the housing 1. A support cylinder 4 is also fixed in the body 1, and the piston rod of the support cylinder 4 is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com