Patents

Literature

79results about How to "Guaranteed drive accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Permanent magnet suspension slide guide for mini-type machine tool

InactiveCN105522400AReduce frictionGuaranteed drive accuracyLarge fixed membersEngineeringMachine tool

The invention discloses a permanent magnet suspension slide guide for a mini-type machine tool. The permanent magnet suspension slide guide for the mini-type machine tool comprises a fixed base, a suspension support, vertical magnetic regulators, horizontal magnetic regulators, a vertical distance-measuring sensor and a horizontal distance-measuring sensor, wherein the two sides of the fixed base are sequentially and symmetrically provided with horizontal magnetic anchor slices, vertical magnetic anchor slices and horizontal distance-measuring anchor slices from outside to inside. The suspension support is of a closed square ring structure, the top of the suspension support is a work platform, and the bottom of the suspension support is a supporting platform. Horizontal magnetic regulating supports are symmetrically arranged on the left side and the right side of the supporting platform. Each horizontal magnetic regulator is fixed to the corresponding horizontal magnetic regulating support through screws. Each vertical magnetic regulator is fixed to the position, beside the corresponding horizontal magnetic regulating support, of the supporting platform through screws. The vertical distance-measuring sensor and the horizontal distance-measuring sensor are fixed to the middle of the supporting platform. The slide guide for the mini-type machine tool has no frictional resistance during transmission, the external disturbance resisting capacity of mobile parts is high, and the machining precision is extremely high.

Owner:JIANGSU MAGLEV TECH CO LTD

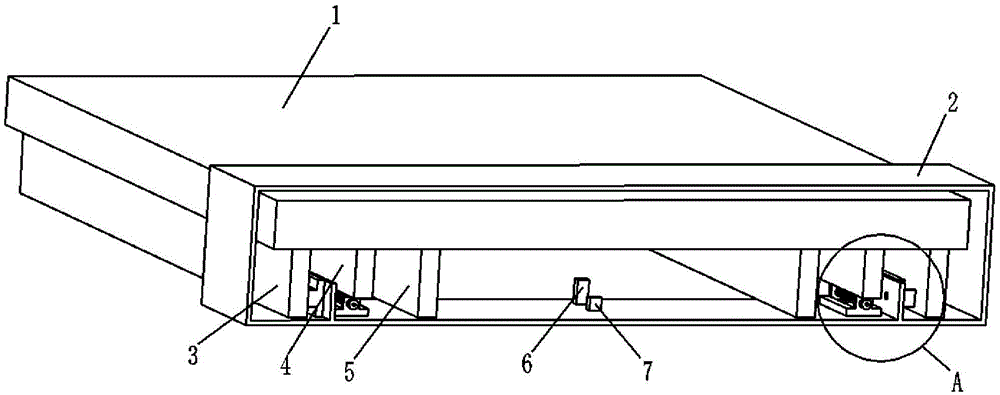

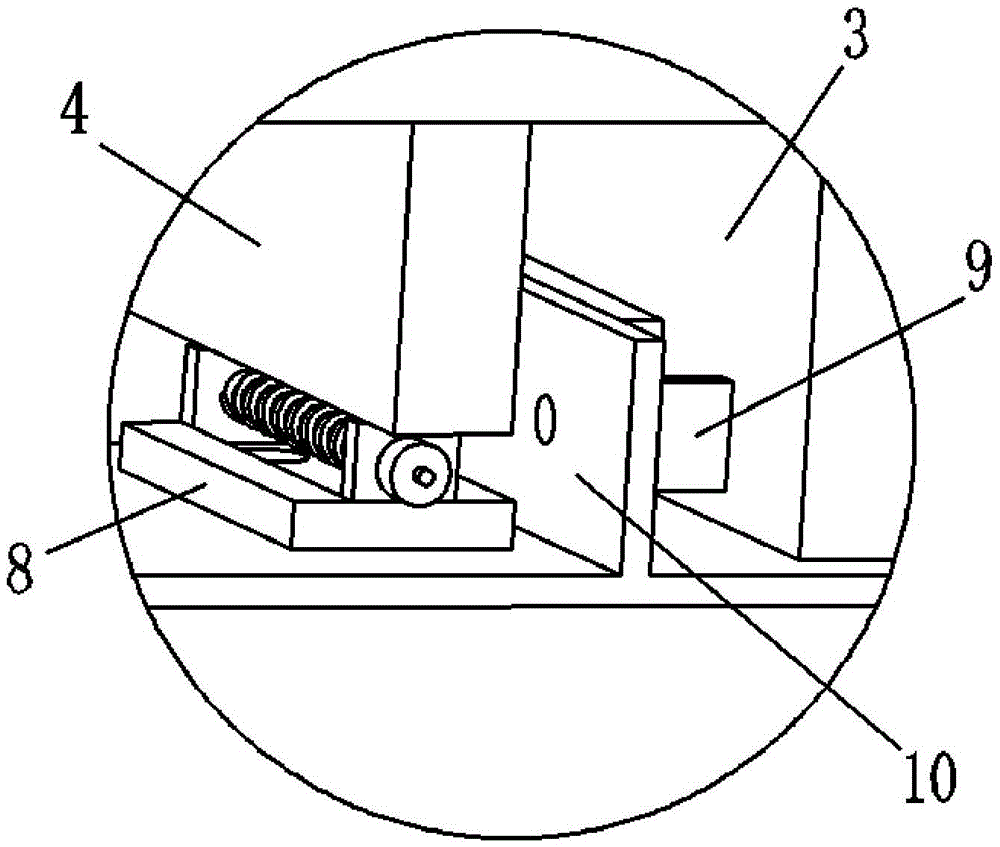

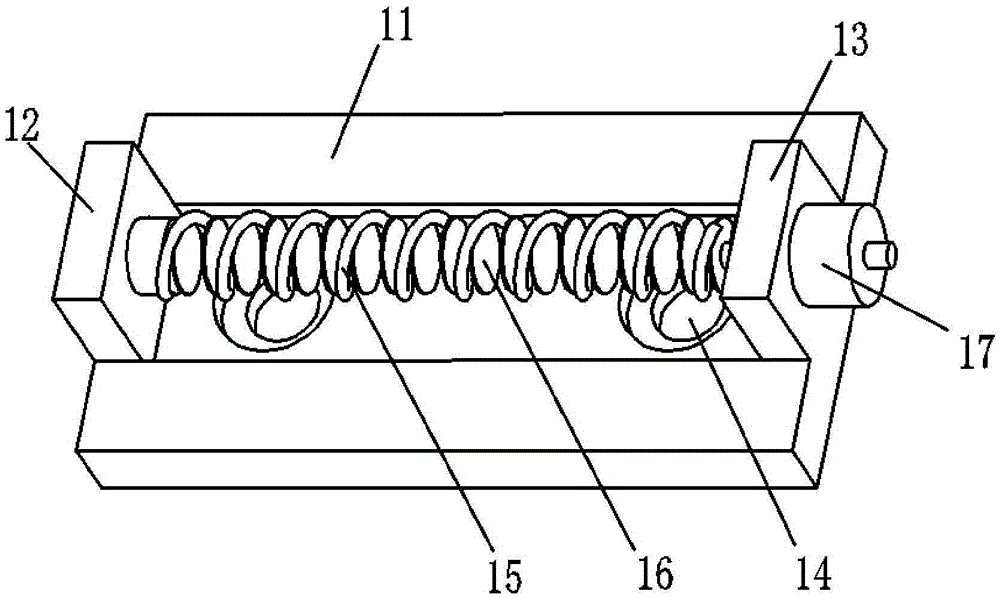

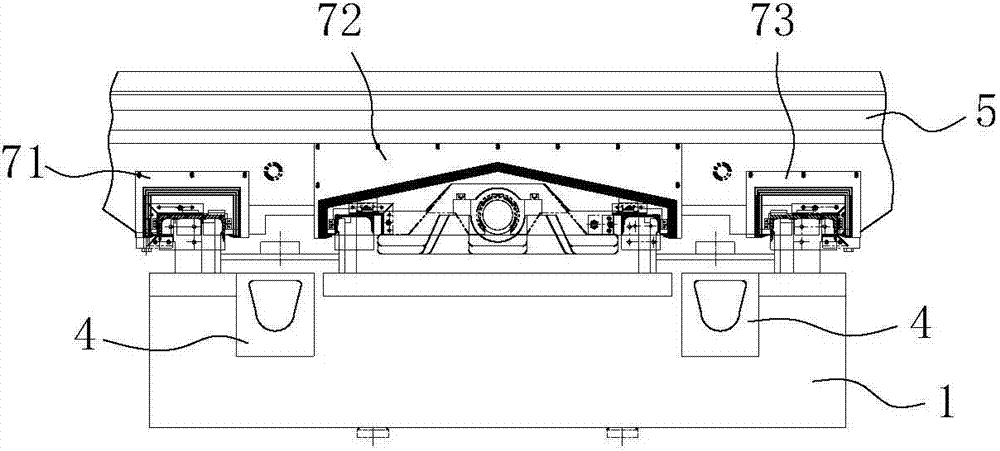

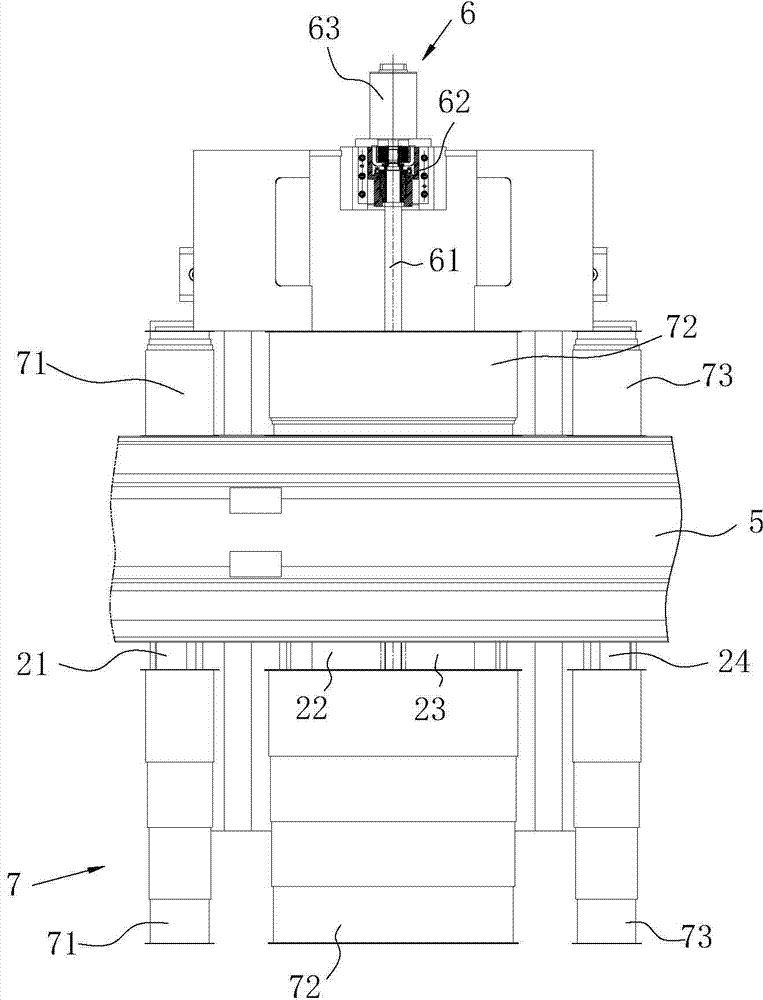

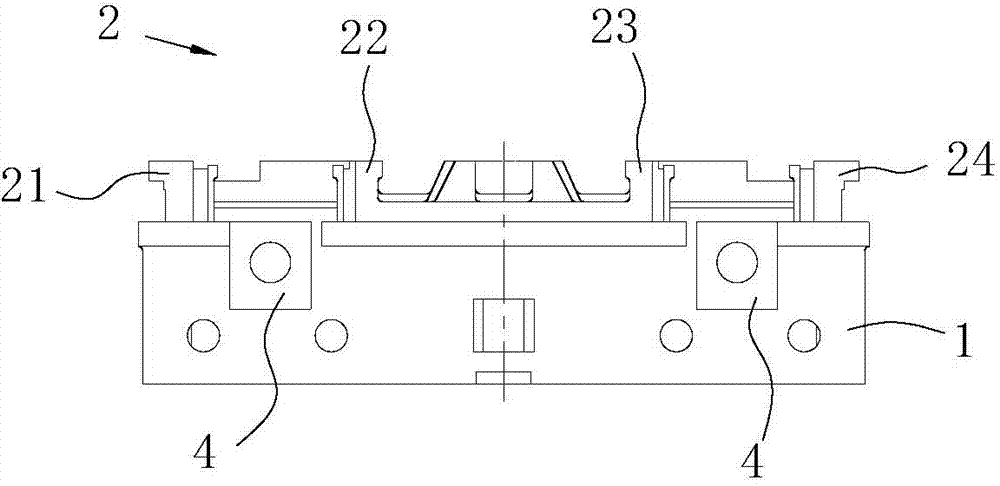

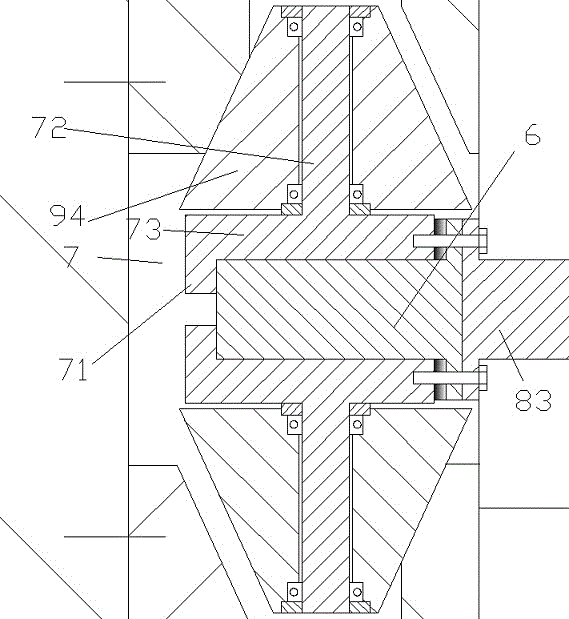

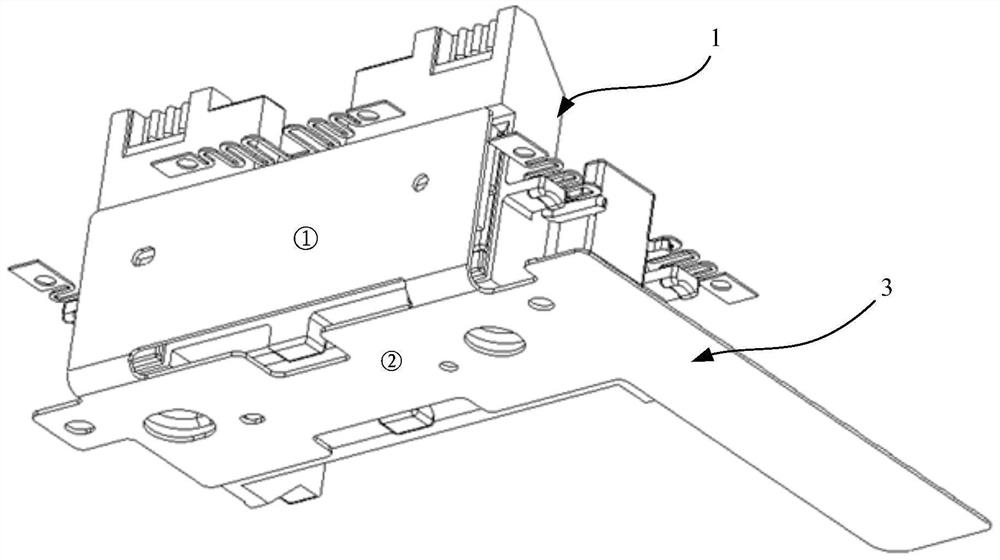

Protection type four-rail support assembly for horizontal coarse framing machine

InactiveCN104511750AImprove pressure bearing capacityGuaranteed drive accuracyLarge fixed membersMaintainance and safety accessoriesEngineeringScrap

The invention discloses a protection type four-rail support assembly for a horizontal coarse framing machine. The protection type four-rail support assembly includes a pedestal and driving platform arranged thereon in a sliding manner, wherein four guide rails parallel to one another are arranged on the pedestal; guide grooves are arranged on one side, close to the pedestal, of the driving platform corresponding to the guide rails; and the guide rails and the pedestal are integrally molded by casting; a protective cover assembly for preventing scrap iron from entering into the guide rails is arranged on each of two sides of the driving platform, each protective cover assembly includes three protective covers, the guide rails on two sides are respectively covered by one protective cover, the two guide rails in the middle are covered by one protective cover, and the three protective covers are all retractable protective covers. Through arranging the four guide rails parallel to one another on the pedestal, the movement stability of the driving platform can be increased; the guide rails and the pedestal are integrally molded by casting, so that the loading capacity of the guide rails can be increased, and the driving accuracy of the guide rail is ensured; with the usage of the protective covers of separating structure, the sizes of the protective covers can be reduced, and the maintenance cost is reduced.

Owner:昆山华都精工精密机械股份有限公司

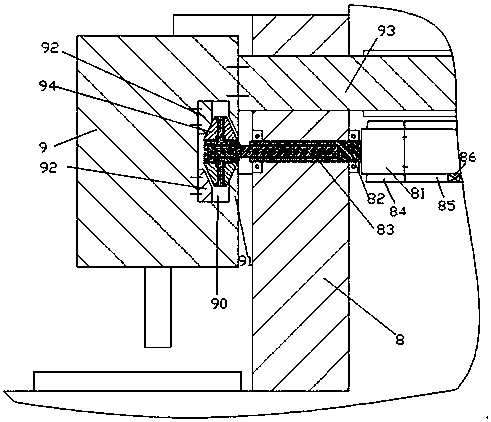

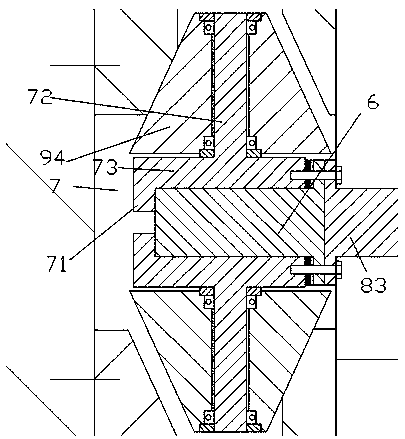

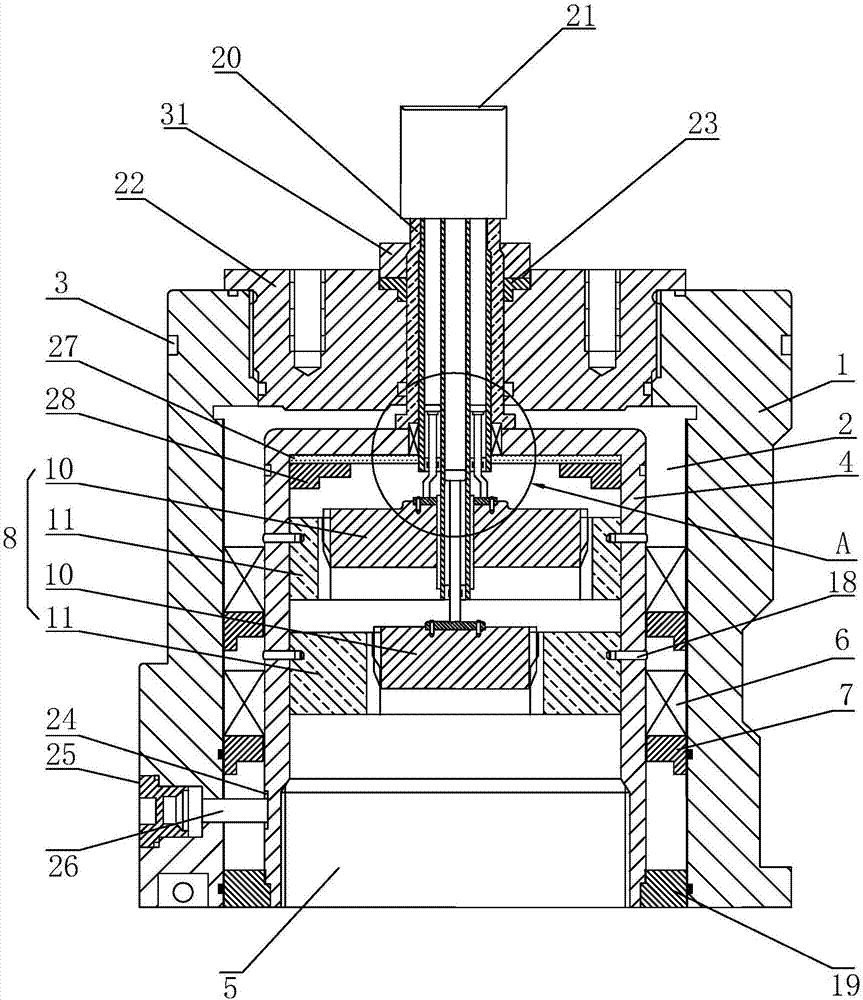

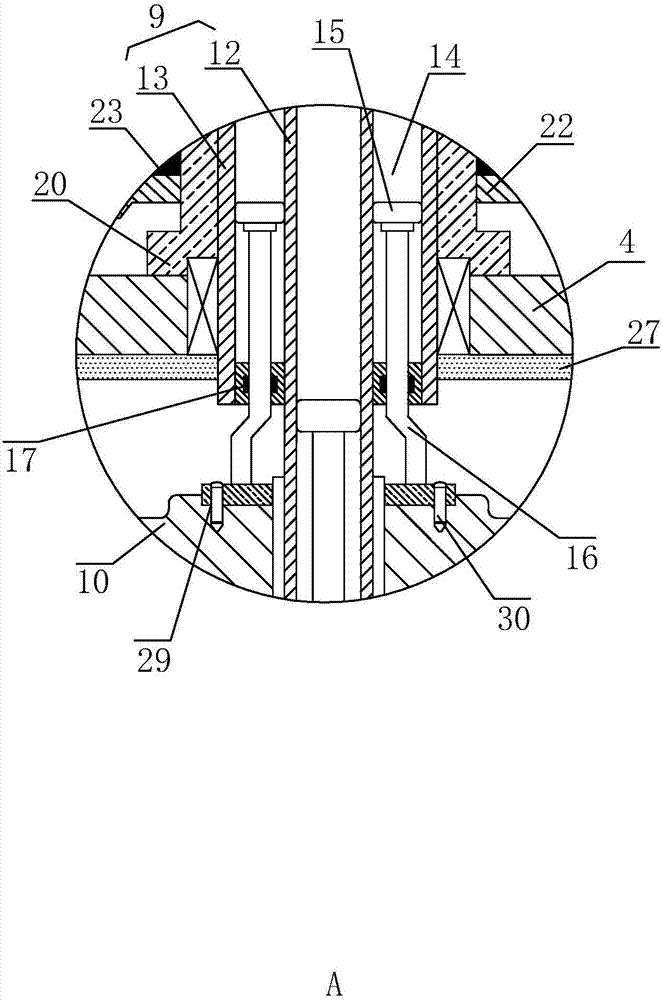

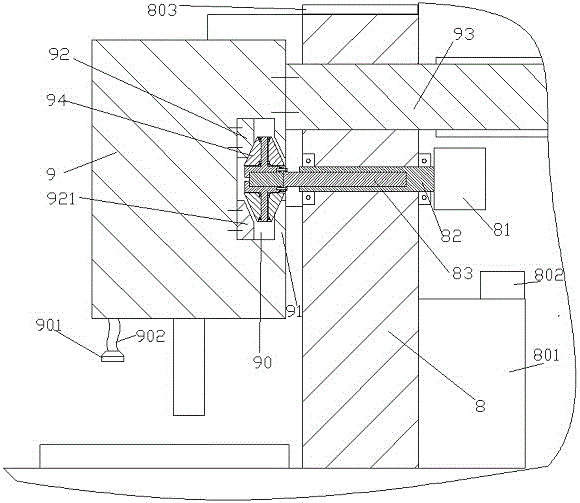

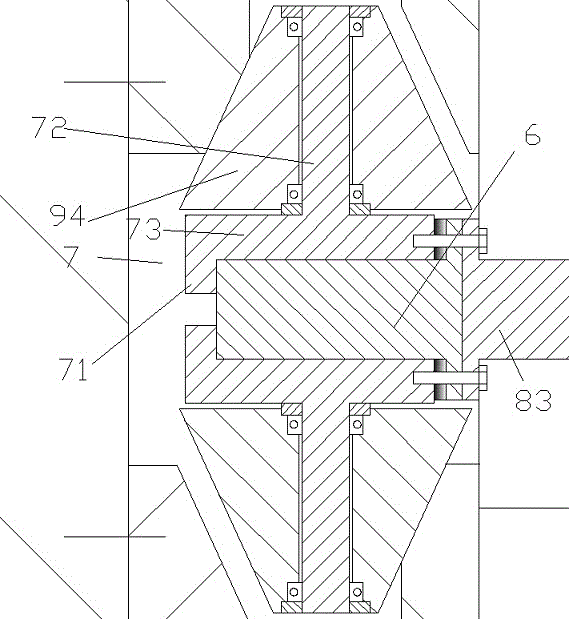

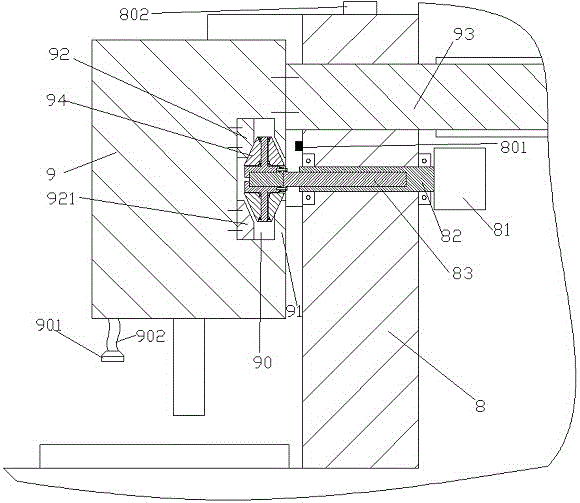

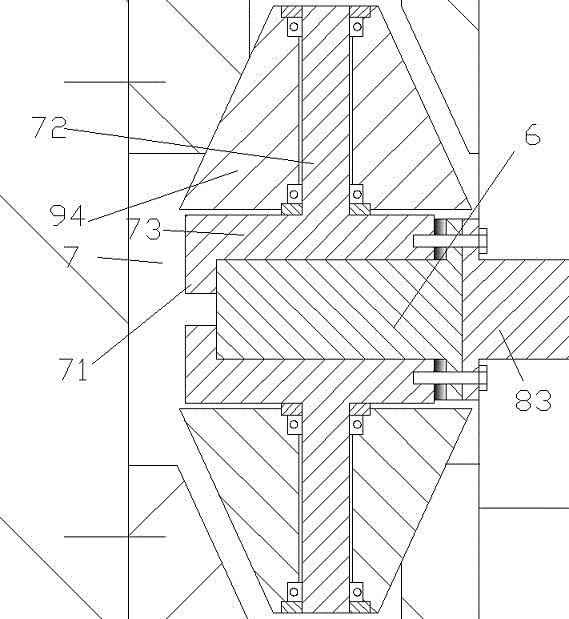

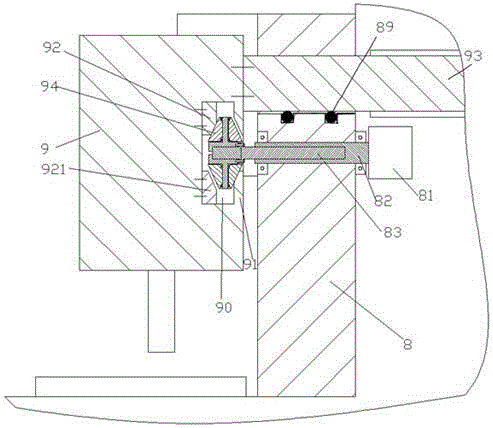

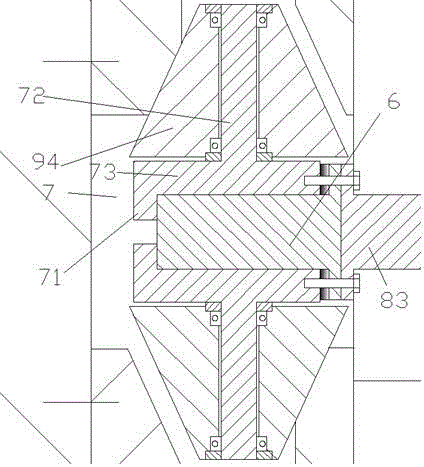

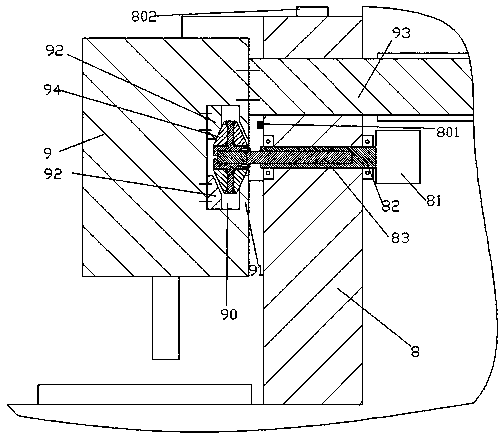

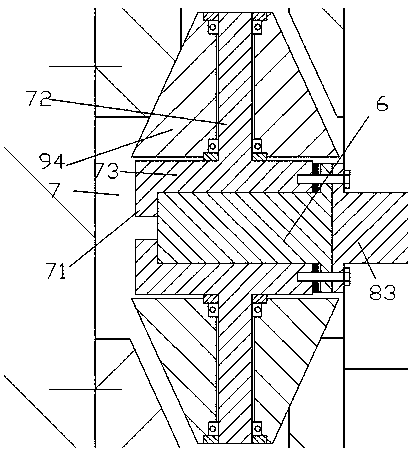

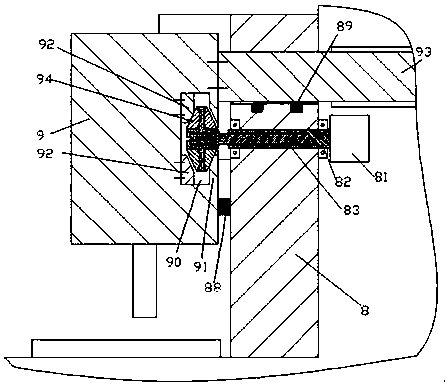

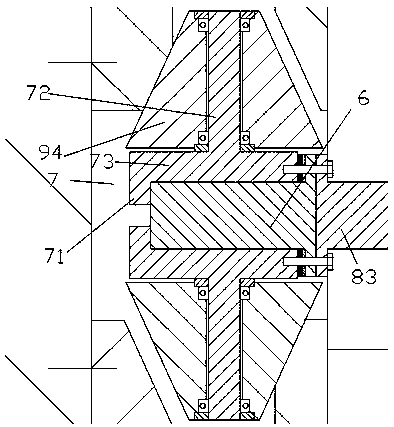

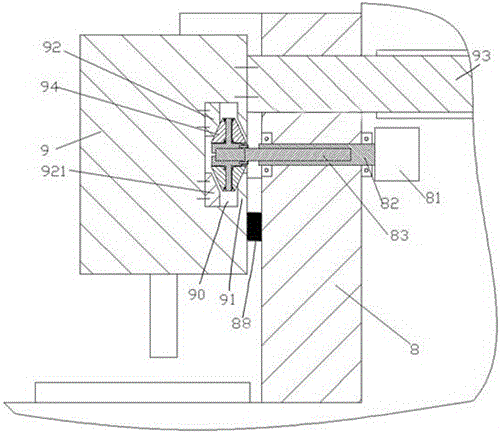

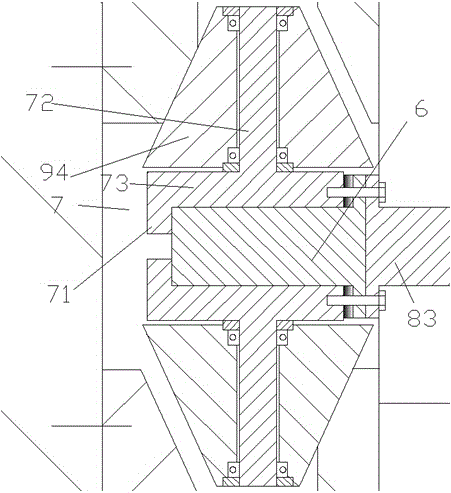

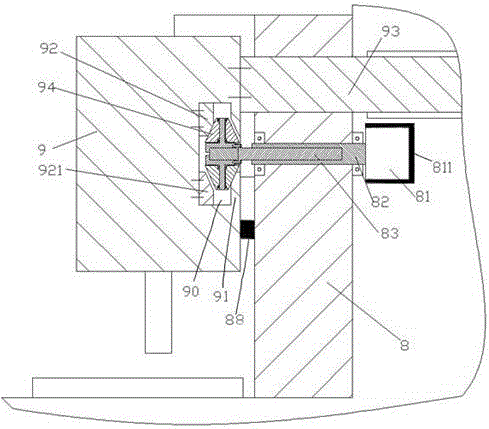

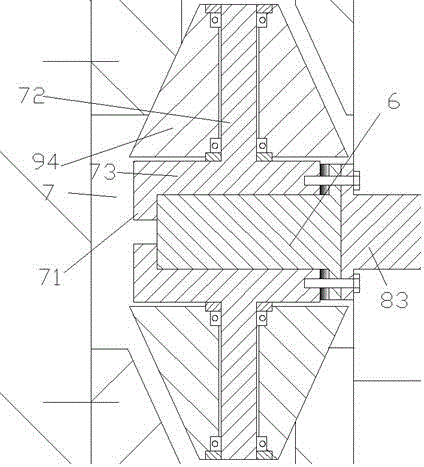

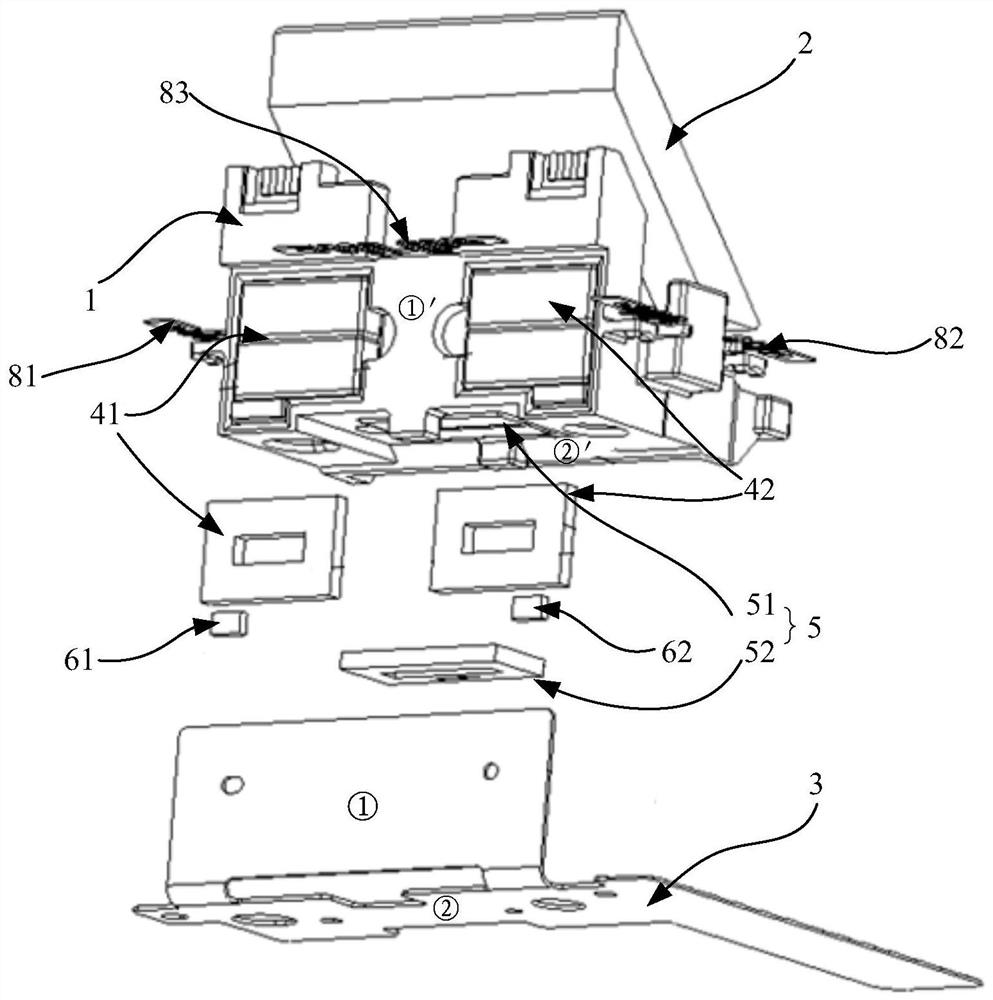

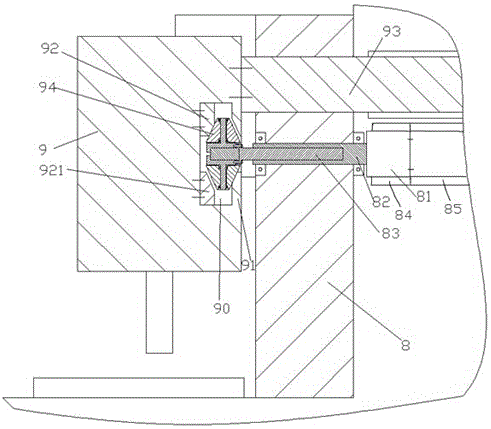

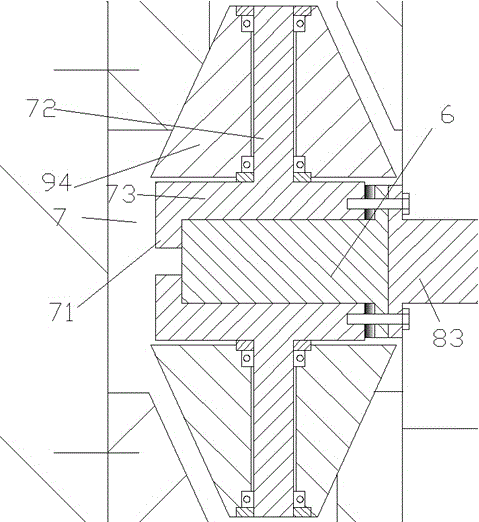

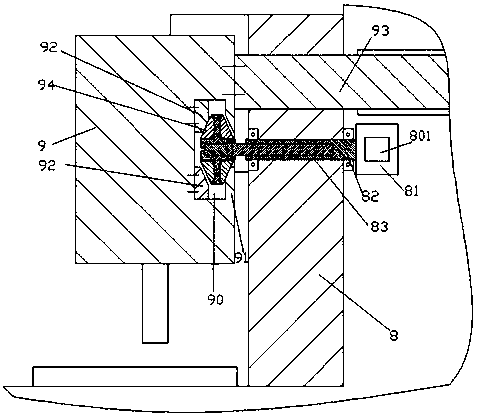

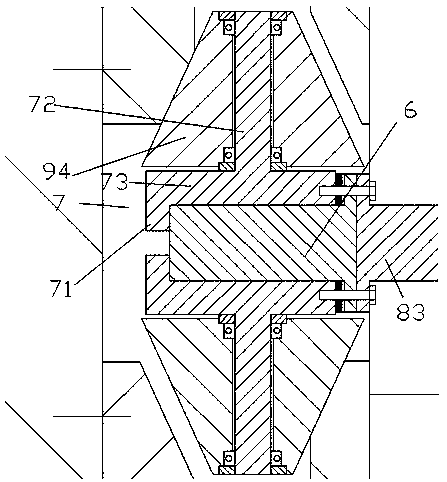

a machining device

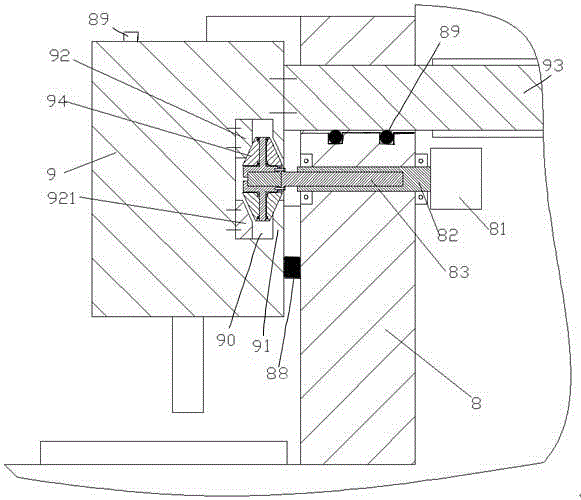

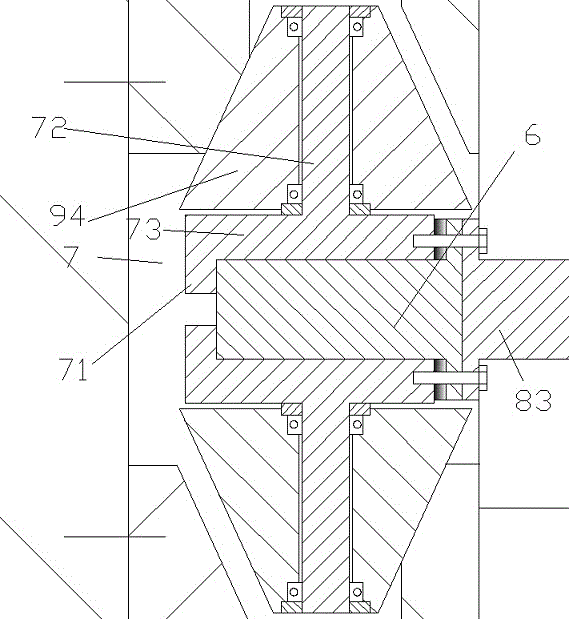

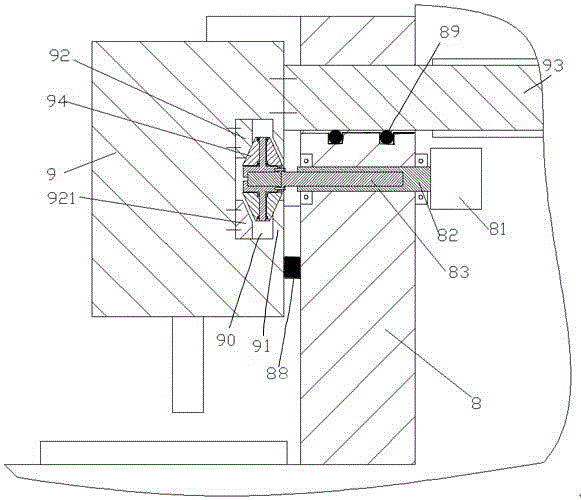

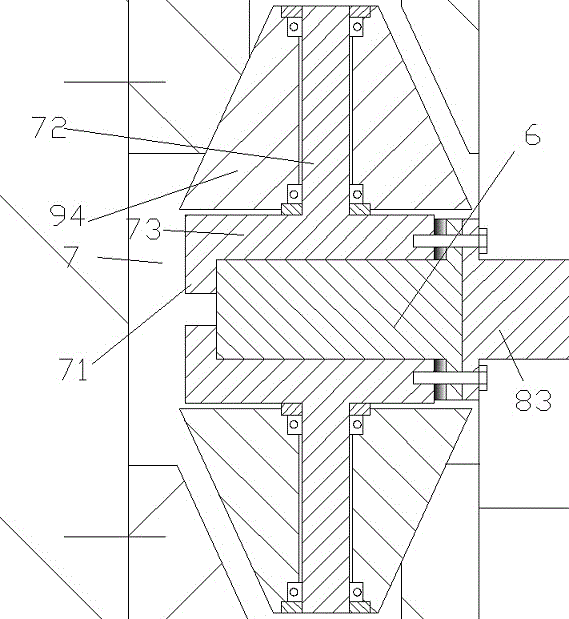

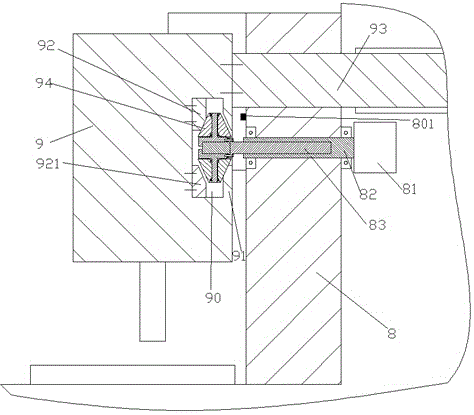

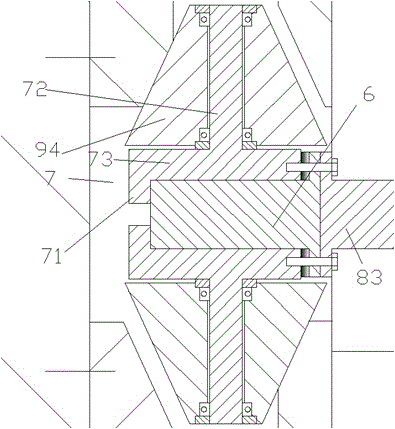

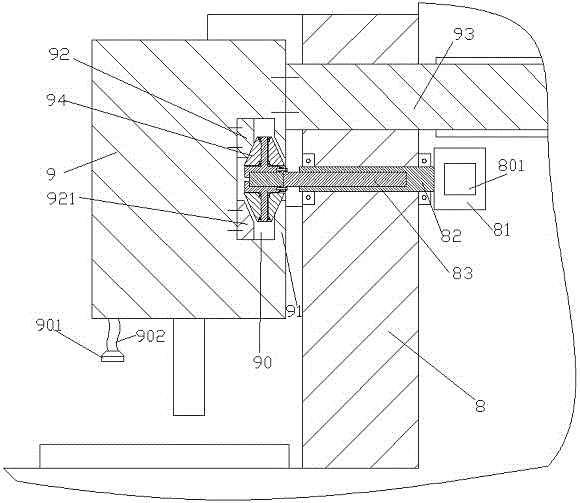

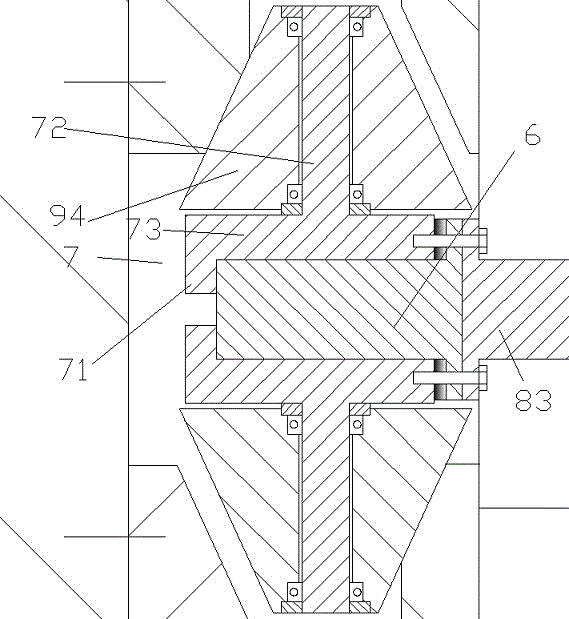

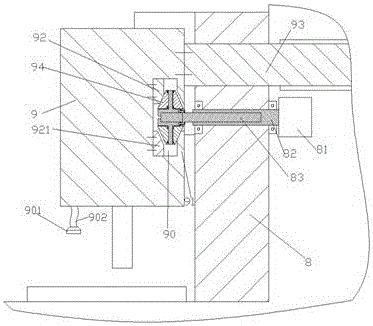

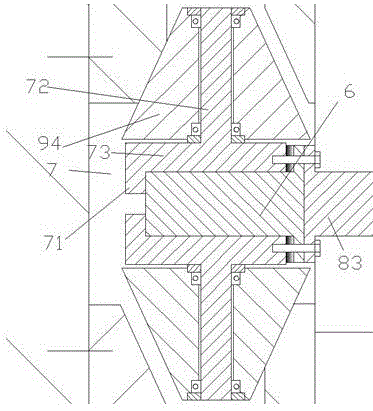

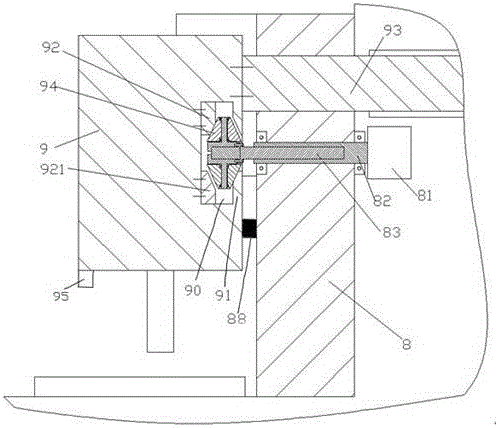

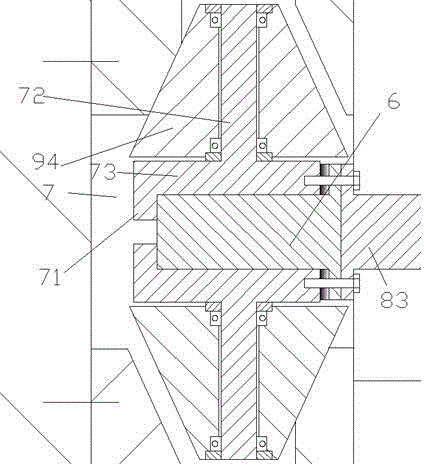

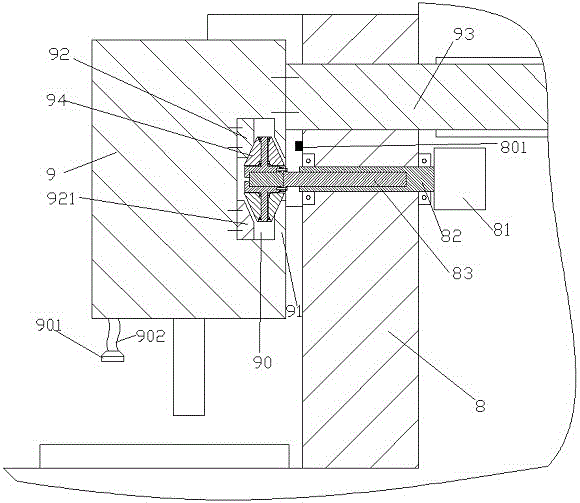

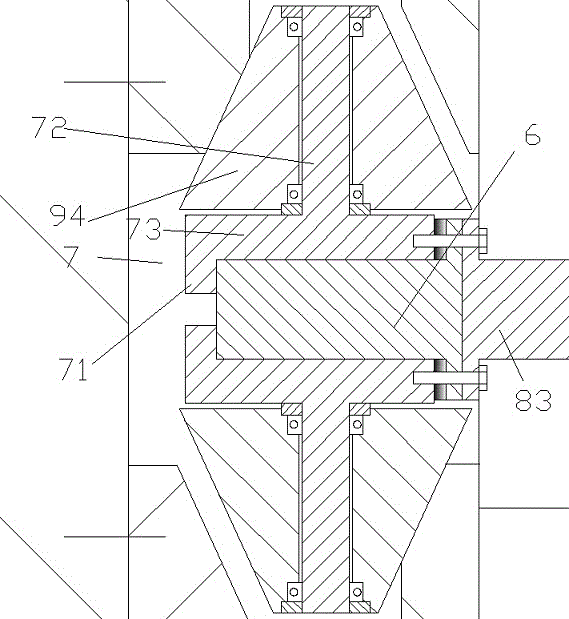

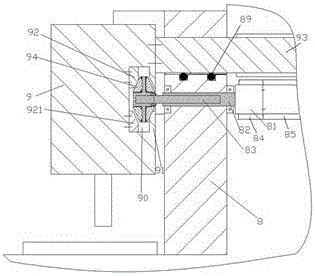

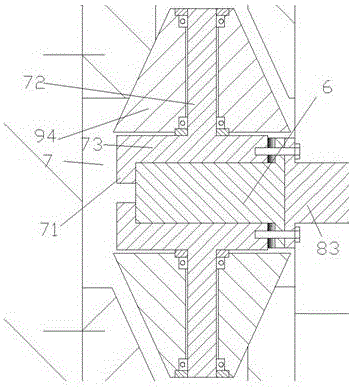

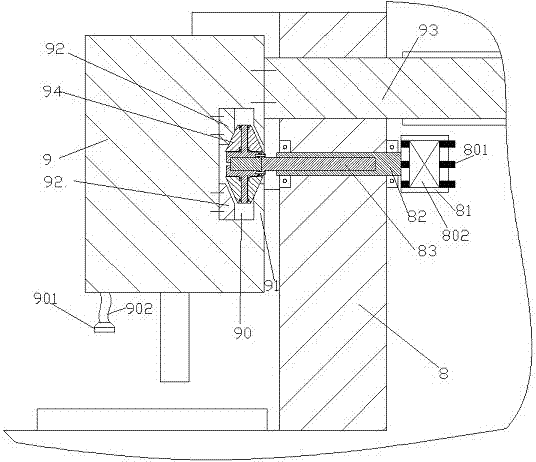

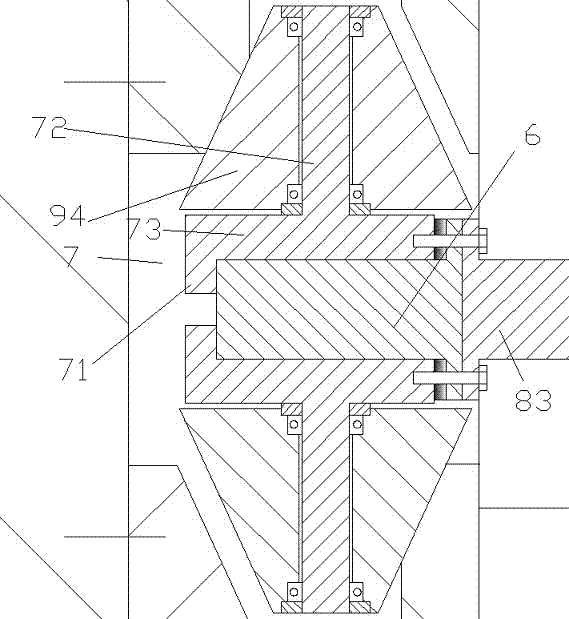

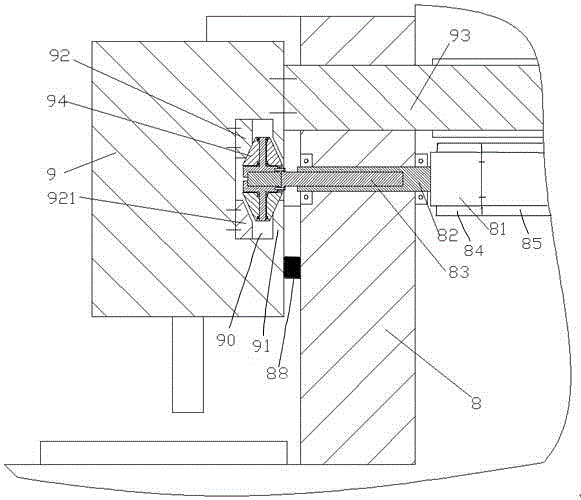

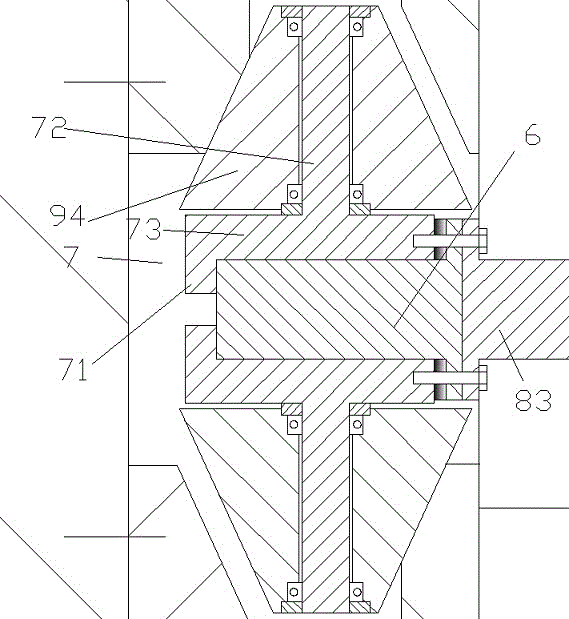

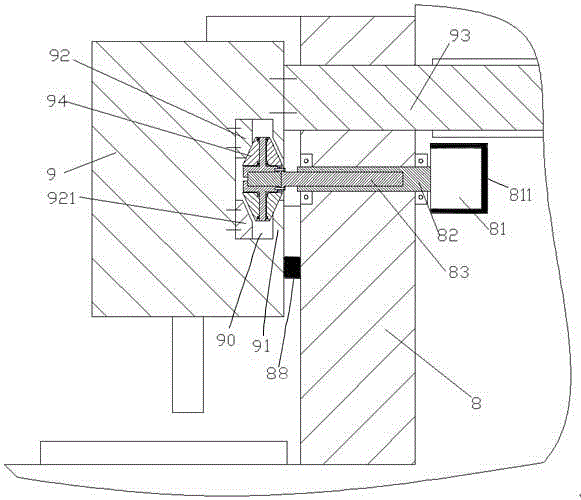

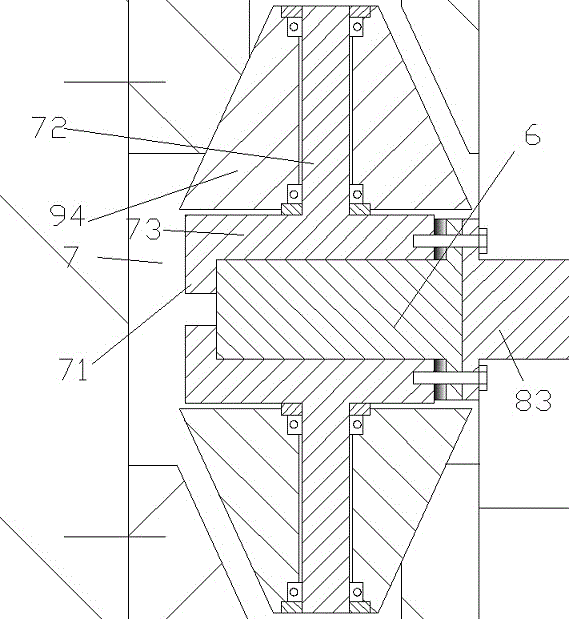

ActiveCN106002433BGuaranteed normal transmissionGuaranteed drive accuracyFeeding apparatusMetal working apparatusReciprocating motionEngineering

The invention relates to a machining device which comprises a rack (8) and a machining head (9) which can be arranged on the rack (8) in a way of moving in a reciprocating way in the front and back direction, wherein a chute cavity (90) which can extend front and back is formed in the machining head (9), and the chute cavity (90) is in rolling fit with an idler wheel pushing device so as to be pulled by the idler wheel pushing device to adjust the position in the left and right direction which is orthogonal to the front and back direction, wherein the idler wheel pushing device comprises a threaded sleeve piece (82) which is rotatably arranged on the rack (8) so as to be in threaded fit with a threaded shifting bar (83).

Owner:TAIZHOU DIANJING MOLD

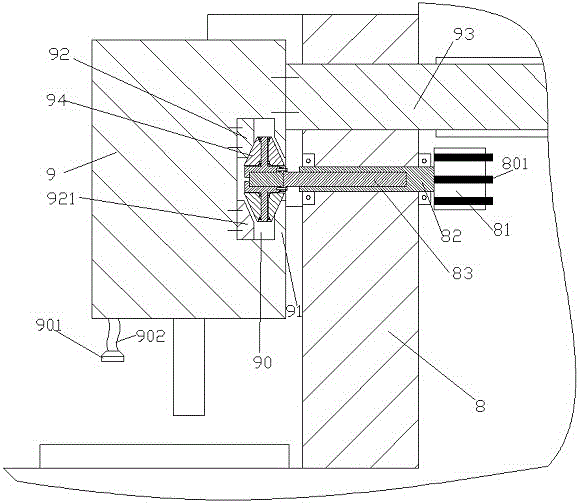

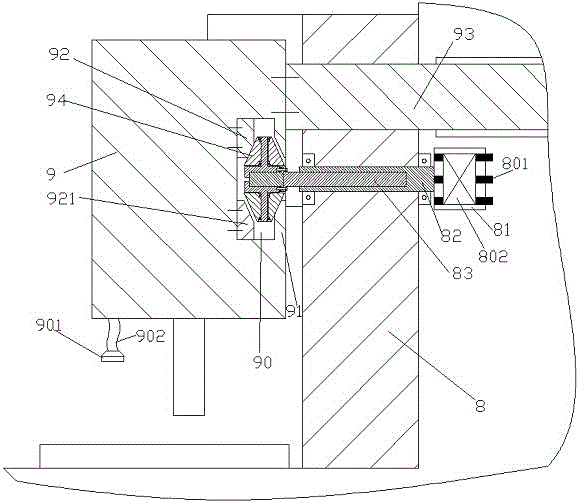

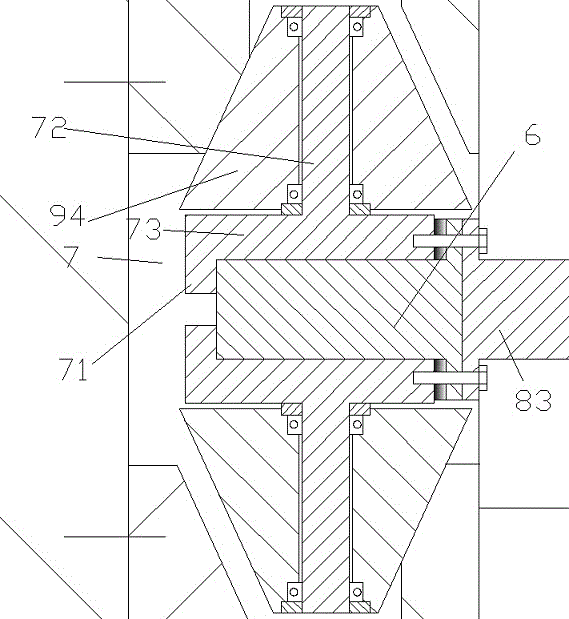

Mechanical machining equipment capable of conveniently adjusting gap

ActiveCN105855975AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusMetal working apparatusPush and pullReciprocating motion

The invention discloses mechanical machining equipment capable of conveniently adjusting a gap. The mechanical machining equipment comprises a rack (8) and a machining head (9) capable of being installed on the rack (8) in the mode of being capable of doing reciprocating motion in the front and back direction, a sliding groove cavity (90) extending in the front and back direction is formed in the machining head (9) and used for being in rolling fit with a rolling wheel pushing device, and then the rolling wheel pushing device pushes and pulls the machining head (9) to adjust the position of the machining head (9) in the left and right direction orthogonal to the front and back direction, wherein the rolling wheel pushing device comprises a threaded sleeve part (82) which is rotatably installed on the rack (8) and used for being in screw-thread fit with a threaded moving rod (83).

Owner:辽阳石化机械设计制造有限公司

Machining device with clearance convenient to regulate

ActiveCN105855904AGuaranteed driving accuracyEasy to adjustGearingLarge fixed membersPush and pullEngineering

A machining device with clearance convenient to regulate comprises a rack (8) and a machining head (9) which is installed on the rack (8) in a reciprocating motion mode in the front-back direction. The machining head (9) is internally provided with a sliding groove cavity (90) extending in the front-back direction. The sliding groove cavity (90) is used for being in rolling fit with an idler wheel thrust unit so that the machining head can be pushed and pulled by the idler wheel thrust unit and the position of the machining head can be regulated in the left-right direction orthogonal to the front-back direction. The idler wheel thrust unit comprises a threaded sleeve part (82) rotationally installed on the rack (8) and used for being in threaded fit with a threaded shifting bar (83).

Owner:安徽全浩铝材有限公司

High-precision valve actuator

ActiveCN107131347AEasy to driveReduce volumeOperating means/releasing devices for valvesLinear motionValve actuator

The invention discloses a high-precision valve actuator. The high-precision valve actuator comprises a shell, a sleeve and a driving assembly for driving the sleeve to rotate. The driving assembly comprises multiple coaxially arranged hydraulic barrels and main bevel gears driven by the hydraulic barrels to move up and down. The main bevel gears are used in cooperation with auxiliary bevel gears arranged in the sleeve, linear motion of piston plates in the hydraulic barrels is converted into rotational motion of the sleeve, and therefore a valve rod is driven to rotate. Due to the fact that the rotation precision of all the main bevel gears is different, the multiple main bevel gears are used in cooperation to rotate, the valve rod can be easily and rapidly rotated to a set angle, and the response speed is high. Fewer drive parts needed by a driving manner are needed, control is also convenient, and the whole valve actuator is small in size and low in weight. All the parts are detachably arranged, and great convenience is also brought to later maintenance of the whole valve actuator.

Owner:SHANGHAI AOZ PETROLEUM EQUIP CO LTD

Energy-saving environment-friendly machining device used for machining head

ActiveCN105855912AGuaranteed driving accuracyEasy to adjustMeasurement/indication equipmentsFeeding apparatusPush and pullEngineering

An energy-saving environment-friendly machining device used for a machining head comprises a rack (8) and the machining head (9) which is installed on the rack (8) and can do reciprocating motion in the front-back direction, and a sliding chute cavity (90) extending in the front-back direction is formed in the machining head (9) and is used for being in rolling fit with a rolling wheel pushing device so that the position in the left-right direction orthogonal to the front-back direction can be adjusted by pushing and pulling the rolling wheel pushing device, wherein the rolling wheel pushing device comprises a thread sleeve part (82) rotationally installed on the rack (8) and used for being in thread fit with a thread moving rod (83).

Owner:JIANGSU JUYUAN ELECTRICAL

Machining device applicable to machining head and capable of running stably

ActiveCN105798629AGuaranteed normal transmissionGuaranteed driving accuracyLarge fixed membersReciprocating motionEngineering

The invention discloses a machining device applicable to a machining head and capable of running stably. The machining device comprises a rack (8) and the machining head (9) which can be mounted on the rack (8) through reciprocating motion in the forward-backward direction; a sliding slot cavity (90) which extends in the forward-backward direction is formed in the machining head (9) and used for being matched with a roller pushing device in a rolling manner, so that a position in the left-right direction orthogonal to such forward-backward direction can be adjusted by pushing or pulling the roller pushing device; and the roller pushing device comprises a threaded sleeve part (82) which is rotatably mounted on the rack (8) and used for being in screw-thread fit with a threaded moving rod (83).

Owner:响水县东源橡塑制品有限公司

Processing device with processing head capable of performing reciprocating motion and preventing motion overtravel

ActiveCN106002430AGuaranteed normal transmissionGuaranteed drive accuracyFeeding apparatusLarge fixed membersPush and pullReciprocating motion

The invention discloses a processing device with a processing head capable of performing reciprocating motion and preventing motion overtravel. The processing device comprises a rack (8) and the processing head (9) which is mounted on the rack (8), capable of performing reciprocating motion in the front-and-back direction, wherein a sliding groove cavity (90) which extends in the front-and-back direction is formed in the processing head (9); the sliding groove cavity (90) is in rolling cooperation with a roller pushing device, so that the roller pushing device pushes and pulls the sliding groove cavity to adjust the position of the sliding groove cavity in the left-right direction orthogonal to the front-and-back direction; and the roller pushing device comprises a threaded sleeve part (82) which is rotatably mounted on the rack (8) and is in thread fit with a threaded moving rod (83).

Owner:江门市宏翔机械有限公司

Machining mechanism used for machining head and provided with safety indicator lamp

ActiveCN105855913AGuaranteed normal transmissionGuaranteed drive accuracyMeasurement/indication equipmentsFeeding apparatusPush and pullReciprocating motion

A machining mechanism used for a machining head and provided with a safety indicator lamp comprises a rack (8) and the machining head (9) which is installed on the rack (8) and can do reciprocating motion in the front-back direction, and a sliding chute cavity (90) extending in the front-back direction is formed in the machining head (9) and is used for being in rolling fit with a rolling wheel pushing device so that the position in the left-right direction orthogonal to the front-back direction can be adjusted by pushing and pulling the rolling wheel pushing device, wherein the rolling wheel pushing device comprises a thread sleeve part (82) rotationally installed on the rack (8) and used for being in thread fit with a thread moving rod (83).

Owner:响水县东源橡塑制品有限公司

Novel machining equipment

ActiveCN106064321AGuaranteed driving accuracyEasy to adjustFeeding apparatusMetal working apparatusPush and pullEngineering

The invention discloses novel machining equipment. The novel machining equipment comprises a rack (8) and a machining head (9), wherein the machining head (9) is mounted on the rack (8) in a manner that the machining head (9) can perform reciprocating motion in the front-back direction. The machining head (9) is internally provided with a sliding groove cavity (90) which extends in the front-back direction. The sliding groove cavity (90) is used for being matched with a rolling wheel pushing device in a rolling manner so that the rolling wheel pushing device can conduct pushing and pulling and the position in the left-right direction orthogonal to the front-back direction can be adjusted. The rolling wheel pushing device comprises a threaded sleeve component (82) which is rotatably mounted on the rack (8) and used for being in thread fit with a threaded moving rod (83).

Owner:TAIZHOU HONGXIANG POWER MACHINERY

Machining head machining mechanism convenient to operate

ActiveCN105855914AGuaranteed normal transmissionGuaranteed driving accuracyMeasurement/indication equipmentsFeeding apparatusPush and pullReciprocating motion

A machining head machining mechanism convenient to operate comprises a rack (8) and a machining head (9) which is installed on the rack (8) and can do reciprocating motion in the front-back direction, and a sliding chute cavity (90) extending in the front-back direction is formed in the machining head (9) and is used for being in rolling fit with a rolling wheel pushing device so that the position in the left-right direction orthogonal to the front-back direction can be adjusted by pushing and pulling the rolling wheel pushing device, wherein the rolling wheel pushing device comprises a thread sleeve part (82) rotationally installed on the rack (8) and used for being in thread fit with a thread moving rod (83).

Owner:江苏中康金属材料有限公司

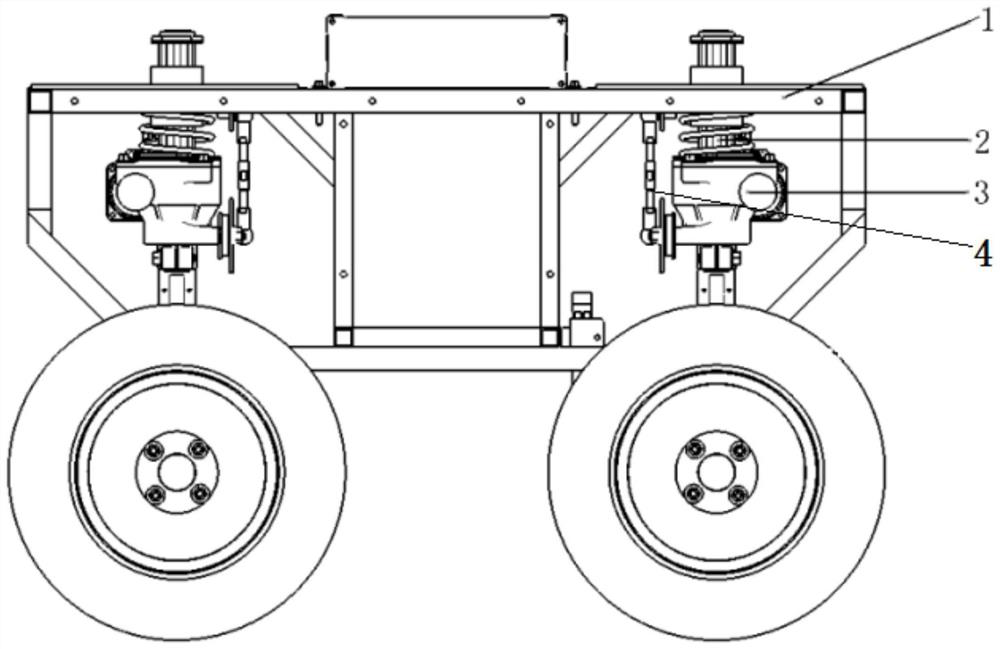

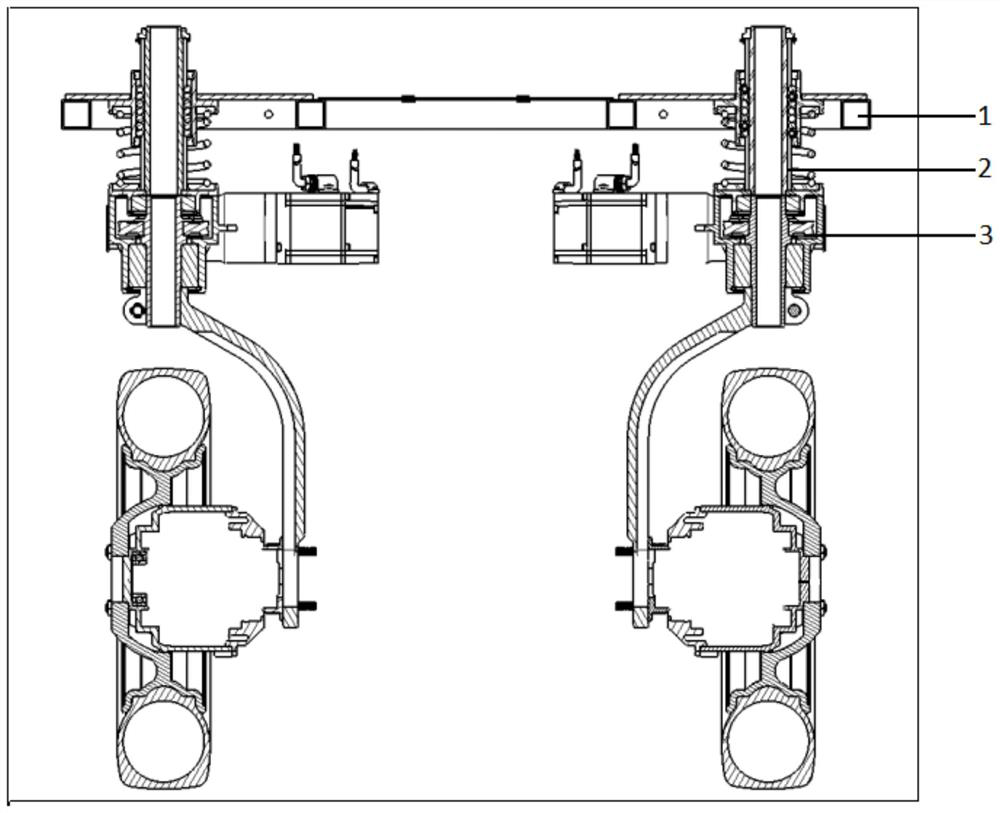

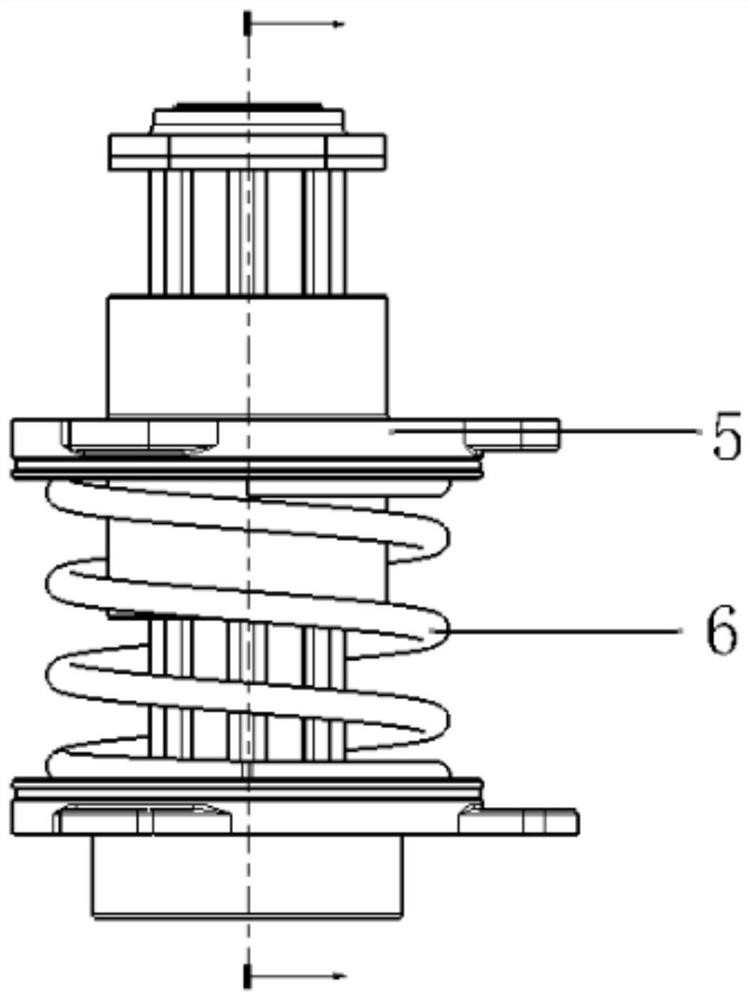

Drive-by-wire chassis system of four-wheel independent steering unmanned vehicle

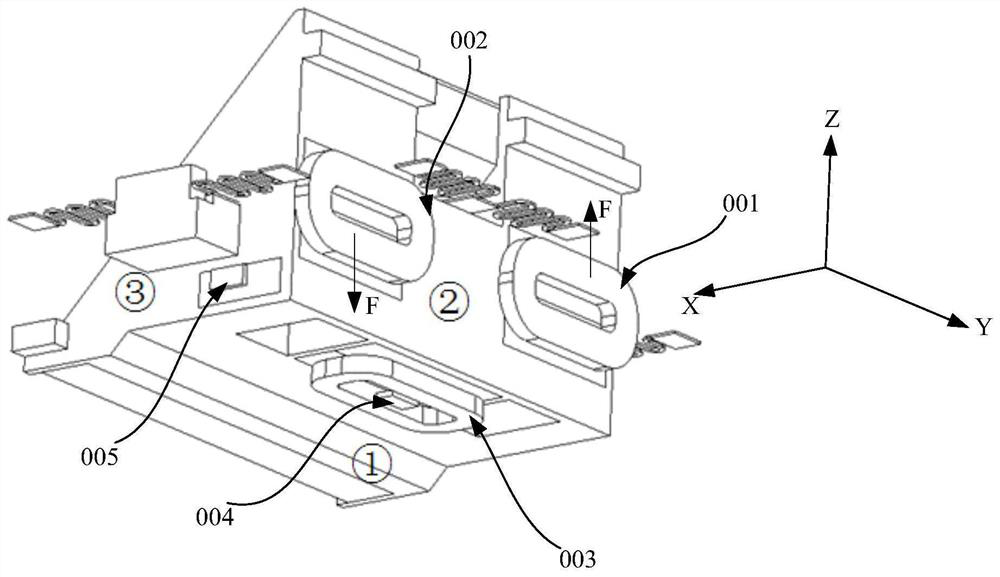

ActiveCN112297745ARealize anti-rotation effectGuaranteed drive accuracySteering partsResilient suspensionsSuspension (vehicle)Rolling chassis

The invention belongs to the technical field of unmanned driving, and relates to a drive-by-wire chassis system of a four-wheel independent steering unmanned vehicle, which comprises a vehicle body framework, a plurality of suspension systems and a plurality of steering systems arranged below the vehicle body framework, and each suspension system corresponds to one steering system. Each suspensionsystem comprises a linear bearing mechanism, a rotary damping mechanism and a spring buffer mechanism, the two ends of each rotary damping mechanism are fixed to the vehicle body framework and the steering system respectively, and the upper end and the lower end of the spring buffer mechanism are elastically connected to the upper end of the linear bearing mechanism and the top of the steering system respectively. Movement of the steering system can be restrained through the linear bearing mechanism, so that the steering system only moves in the vertical direction, the anti-rotation effect onwheels in the damping process is achieved, and the buffer spring and the rotary damping mechanism work at the same time so as to effectively absorb energy generated by shaking of the vehicle.

Owner:LAUNCH DESIGN INC LTD

Adjustable machining device applicable to machining head

ActiveCN105798630AGuaranteed normal transmissionGuaranteed driving accuracyLarge fixed membersReciprocating motionEngineering

The invention discloses an adjustable machining device applicable to a machining head. The adjustable machining device comprises a rack (8) and the machining head (9) which can be mounted on the rack (8) through reciprocating motion in the forward-backward direction; a sliding slot cavity (90) which extends in the forward-backward direction is formed in the machining head (9) and used for being matched with a roller pushing device in a rolling manner, so that a position in the left-right direction orthogonal to such forward-backward direction can be adjusted by pushing or pulling the roller pushing device; and the roller pushing device comprises a threaded sleeve part (82) which is rotatably mounted on the rack (8) and used for being in screw-thread fit with a threaded moving rod (83).

Owner:南通格美工业数控设备有限公司

Machining device used for machining head and capable of moving in reciprocating way

InactiveCN106002326AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusLarge fixed membersReciprocating motionEngineering

A reciprocating processing device for a processing head, comprising a frame (8) and a processing head (9) reciprocally mounted on the frame (8) in the front-rear direction, the processing head (9) is provided with a chute cavity ( 90 ) extending in the front and rear direction, and the chute cavity ( 90 ) is used to roll and cooperate with the roller pusher so as to be pushed and pulled by the roller pusher to adjust the position perpendicular to the The position in the left-right direction of the front-rear direction, wherein the roller pushing device includes a threaded sleeve member (82) rotatably mounted on the frame (8) for threaded engagement with a threaded moving rod (83).

Owner:李长娟

Processing device convenient for adjusting gap

ActiveCN105904233AGuaranteed normal transmissionGuaranteed driving accuracyLarge fixed membersMaintainance and safety accessoriesPush and pullReciprocating motion

The invention discloses a processing device convenient for adjusting a gap. The processing device comprises a rack (8) and a processing head (9) mounted on the rack (8) in a manner of doing reciprocating motion in the front-to-back direction, wherein a sliding chute cavity (90) capable of extending in the front-to-back direction is formed in the processing head (9), and is in rolling fit with a roller push device, so that the sliding chute cavity (90) is pushed and pulled by the roller push device, to adjust the position in the left-to-right direction orthogonal to the front-to-back direction; the roller push device comprises a threaded sleeve piece (82) which is mounted on the rack (8) in a rotatable manner and is in threaded fit with a threaded moving rod (83).

Owner:NANTONG XUNDA RUBBER PLASTIC MFG CO LTD

Intelligent control machining device for machining head

ActiveCN105855911AGuaranteed normal transmissionGuaranteed driving accuracyMeasurement/indication equipmentsFeeding apparatusReciprocating motionEngineering

An intelligent control machining device for a machining head comprises a rack (8) and the machining head (9) which can reciprocate in the front-back direction and is mounted on the rack (8). A sliding groove cavity (90) extending in the front-back direction is formed in the machining head (9) and used for being in rolling fit with a roller push device to be pulled by the roller push device so that the position of the sliding groove cavity in the left-right direction orthogonal to the front-back direction can be adjusted. The roller push device comprises a threaded sleeve part (82) rotationally mounted on the rack (8) and used for being in thread fit with a threaded movable rod (83).

Owner:江苏蓝鹰液压科技有限公司

Mechanical processing device capable of reciprocating motion

InactiveCN105817906AGuaranteed normal transmissionGuaranteed drive accuracyLarge fixed membersPush and pullReciprocating motion

A mechanical processing device capable of reciprocating motor comprises a rack (8) and a processing head (9) which can be installed on the rack (8) in the form of back-and-forth reciprocating motion, wherein a slide groove cavity (90) which can extend in the back-and-forth direction is disposed in the processing head (9); the slide groove cavity (90) is used to form rolling fitting with a roller pushing device so as to be pushed and pulled by the roller pushing device, so that the position in the left-right direction which is orthogonal to the back-and-forth direction can be adjusted; and the roller pushing device comprises a threaded sleeve part (82) which is installed on the rack (8) in a rotatable manner, and the threaded sleeve part is used for threaded fitting with a threaded moving rod (83).

Owner:李长娟

A processing mechanism for a processing head with convenient operation

ActiveCN105855914BGuaranteed normal transmissionEliminate gapsMeasurement/indication equipmentsFeeding apparatusPush and pullReciprocating motion

A machining head machining mechanism convenient to operate comprises a rack (8) and a machining head (9) which is installed on the rack (8) and can do reciprocating motion in the front-back direction, and a sliding chute cavity (90) extending in the front-back direction is formed in the machining head (9) and is used for being in rolling fit with a rolling wheel pushing device so that the position in the left-right direction orthogonal to the front-back direction can be adjusted by pushing and pulling the rolling wheel pushing device, wherein the rolling wheel pushing device comprises a thread sleeve part (82) rotationally installed on the rack (8) and used for being in thread fit with a thread moving rod (83).

Owner:江苏中康金属材料有限公司

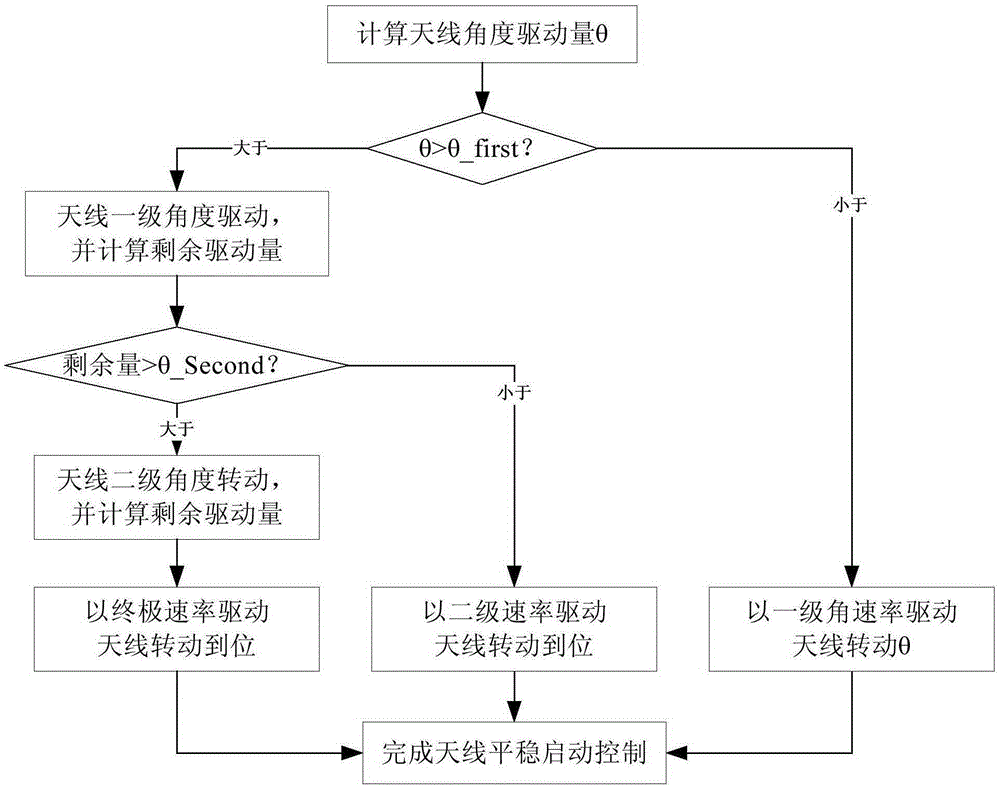

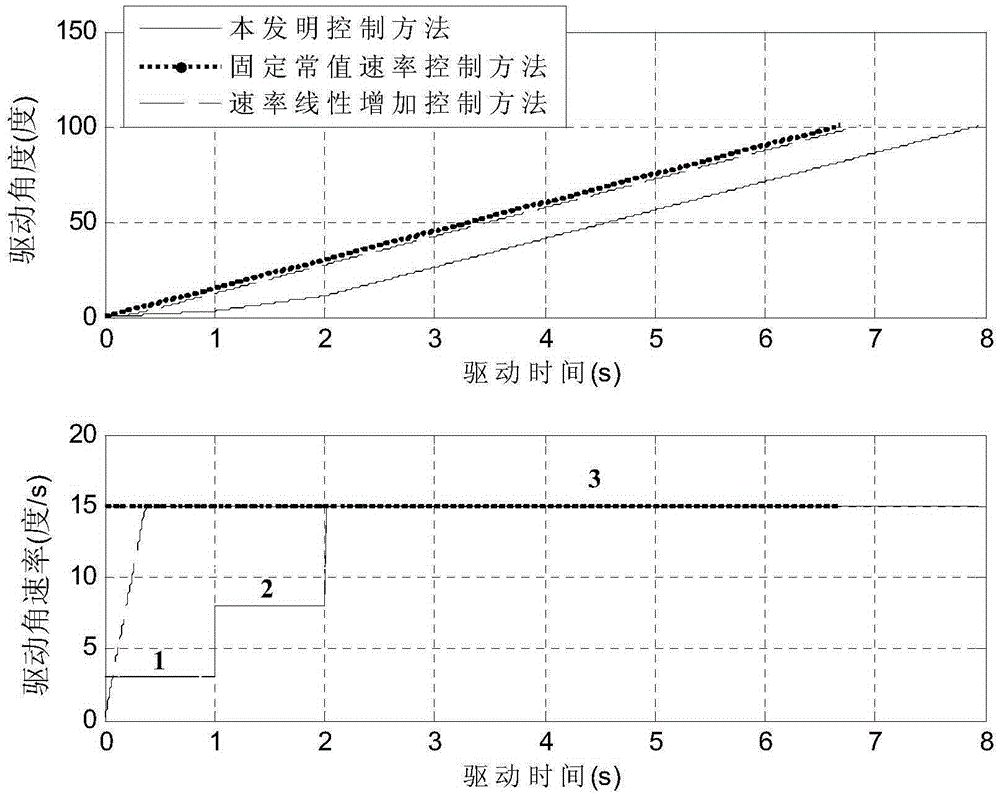

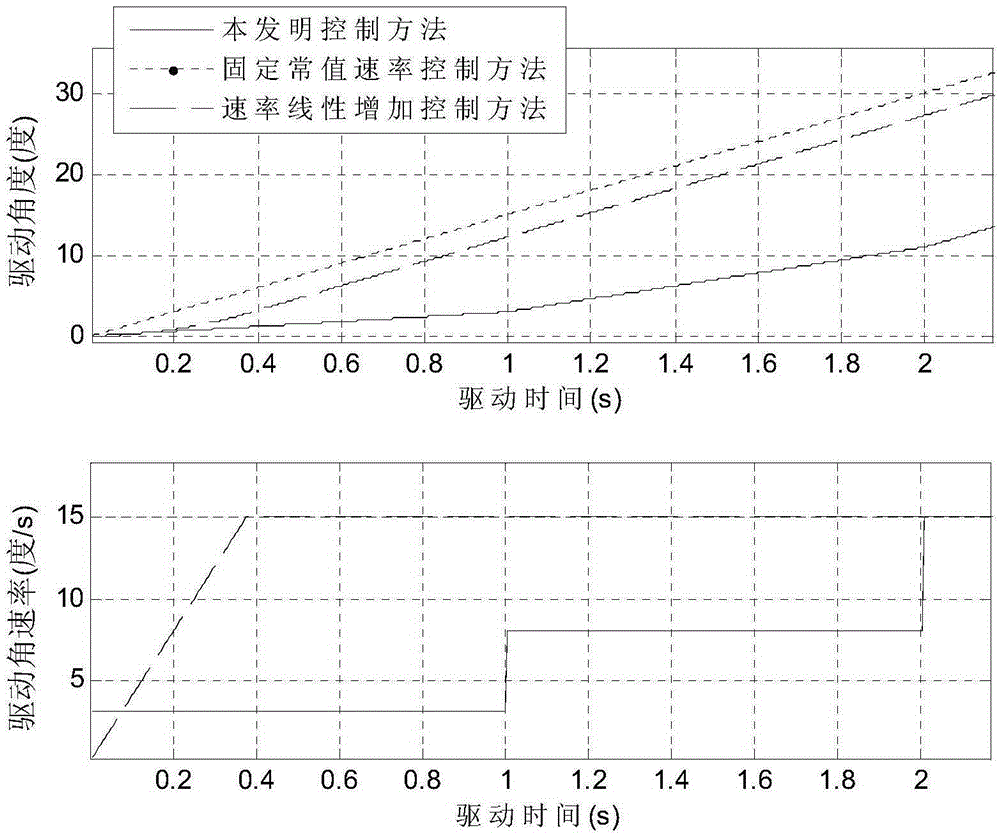

Smooth driving control method of satellite antenna

The invention relates to a smooth driving control method of a satellite antenna. The method comprises the following steps of firstly, calculating an angle driving quantity Theta of the antenna according to a target angle of the antenna, judging whether the angle driving quantity Theta is greater than a primary angle, directly driving the antenna to complete driving if the angle driving quantity Theta is not greater than the primary angle, otherwise carrying out primary angle driving of the antenna; secondly, calculating remaining angle driving quantity, comparing the remaining angle driving quantity with a secondary angle, directly driving the antenna to complete driving if the remaining angle driving quantity is smaller than the secondary angle, otherwise carrying out secondary angle driving of the antenna; and finally, calculating the remaining angle driving quantity, and directly driving the antenna to complete driving. According to the method, the antenna rotation is controlled by means of three-stage driving rate, the antenna can be rapidly driven to reach the target angle, moreover, the problem of system instability caused by overlarge angular rate when the antenna is instantly started is avoided, the smooth driving control method is completely and suitably used for a large rotational inertia antenna, and a communication-in-moving antenna is rapidly and smoothly driven during satellite replace.

Owner:BEIJING INST OF AEROSPACE CONTROL DEVICES

A processing device with reciprocating motion of processing head and indicator light

ActiveCN106041602BGuaranteed normal transmissionEliminate gapsFeeding apparatusMetal working apparatusReciprocating motionEngineering

The invention discloses a processing device with a processing head capable of achieving reciprocating motion and an indicator light. The processing device comprises a frame (8) and a processing head (9), wherein the processing head (9) is mounted on the frame (8) in a way of achieving reciprocating motion in front and back directions; a chute cavity (90) extending in front and back directions is formed in the processing head (9) and is in rolling fit with a rolling wheel pushing device, so that the processing head is pushed or pulled by the rolling wheel pushing device to adjust positions in left and right directions orthogonal to the front and back directions; and the rolling wheel pushing device comprises a threaded sleeve part (82) which is rotatably mounted on the frame (8) and is in threaded fit with a threaded movable rod (83).

Owner:CHONGQING HANYUAN MACHINERY

A mechanical processing device for convenient adjustment of clearance

ActiveCN105855904BGuaranteed normal transmissionEliminate gapsGearingLarge fixed membersPush and pullReciprocating motion

A machining device with clearance convenient to regulate comprises a rack (8) and a machining head (9) which is installed on the rack (8) in a reciprocating motion mode in the front-back direction. The machining head (9) is internally provided with a sliding groove cavity (90) extending in the front-back direction. The sliding groove cavity (90) is used for being in rolling fit with an idler wheel thrust unit so that the machining head can be pushed and pulled by the idler wheel thrust unit and the position of the machining head can be regulated in the left-right direction orthogonal to the front-back direction. The idler wheel thrust unit comprises a threaded sleeve part (82) rotationally installed on the rack (8) and used for being in threaded fit with a threaded shifting bar (83).

Owner:安徽全浩铝材有限公司

Machining device capable of achieving precise machining

ActiveCN105855916AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusLarge fixed membersPush and pullReciprocating motion

The invention discloses a machining device capable of achieving precise machining. The machining device comprises a rack (8) and a machining head (9) capable of being installed on the rack (8) in the mode of being capable of doing reciprocating motion in the front and back direction, a sliding groove cavity (90) extending in the front and back direction is formed in the machining head (9) and used for being in rolling fit with a rolling wheel pushing device, and then the rolling wheel pushing device pushes and pulls the machining head (9) to adjust the position of the machining head (9) in the left and right direction orthogonal to the front and back direction, wherein the rolling wheel pushing device comprises a threaded sleeve part (82) which is rotatably installed on the rack (8) and used for being in screw-thread fit with a threaded moving rod (83).

Owner:昌黎县昊良机械设备制造有限公司

Machining device achieving precise machining and provided with reciprocating motion type machining head

ActiveCN106041551AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusLarge fixed membersReciprocating motionEngineering

A machining device achieving precise machining and provided with a reciprocating motion type machining head comprises a machine frame (8) and the machining head (9) which is installed on the machine frame (8) and can conduct reciprocating motion in the front-back direction. A sliding groove cavity (90) extending in the front-back direction is formed in the machining head (9). The sliding groove cavity (90) is used for being in rolling fit with a rolling wheel pushing device so that the rolling wheel pushing device pushes or pulls the machining head to adjust the position of the machining head in the left-right direction which is orthogonal to the front-back direction, wherein the rolling wheel pushing device comprises a threaded sleeve piece (82) which is rotationally installed on the machine frame (8) and used for being in screw thread fit with a threaded moving rod (83).

Owner:泰州市翔顺动力机械有限公司

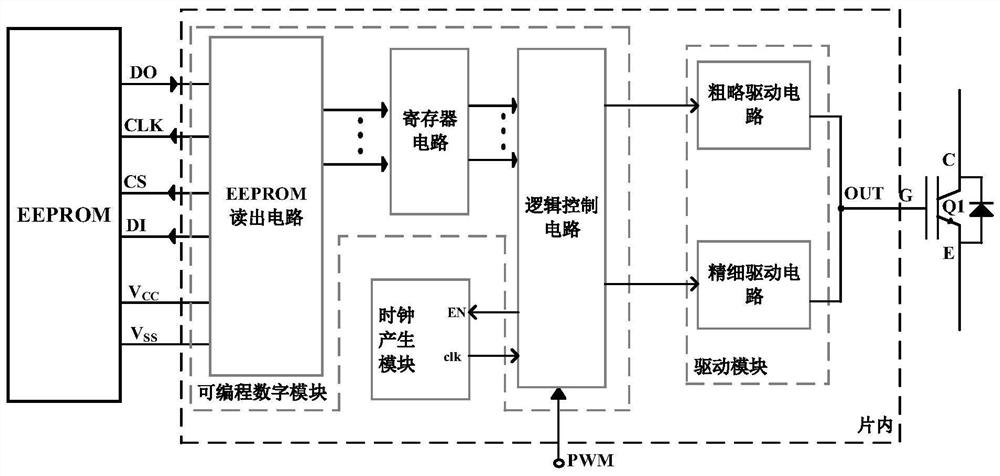

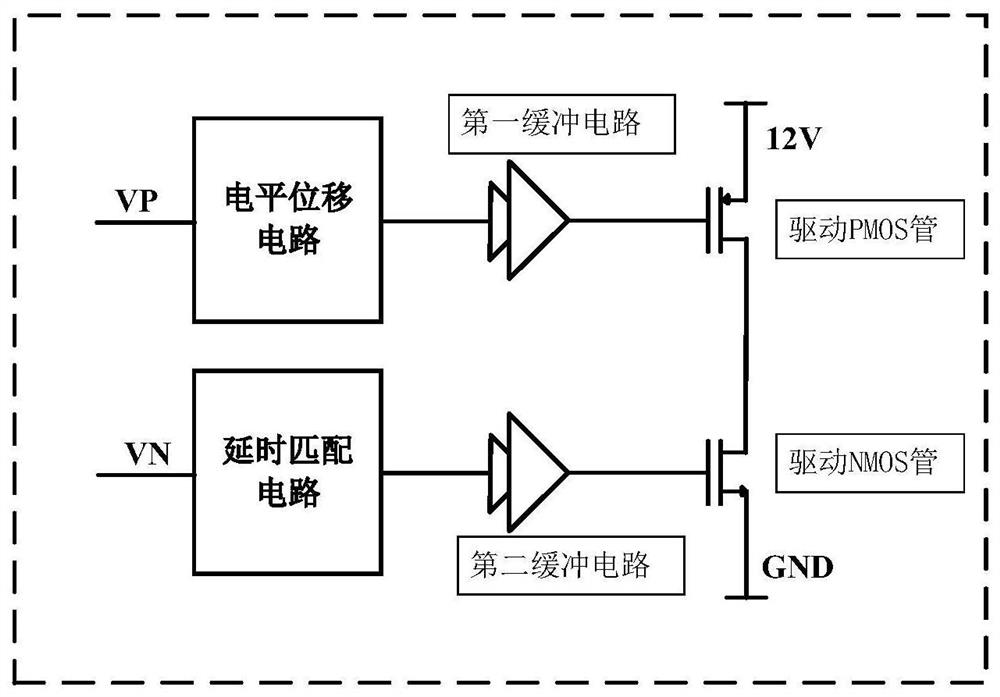

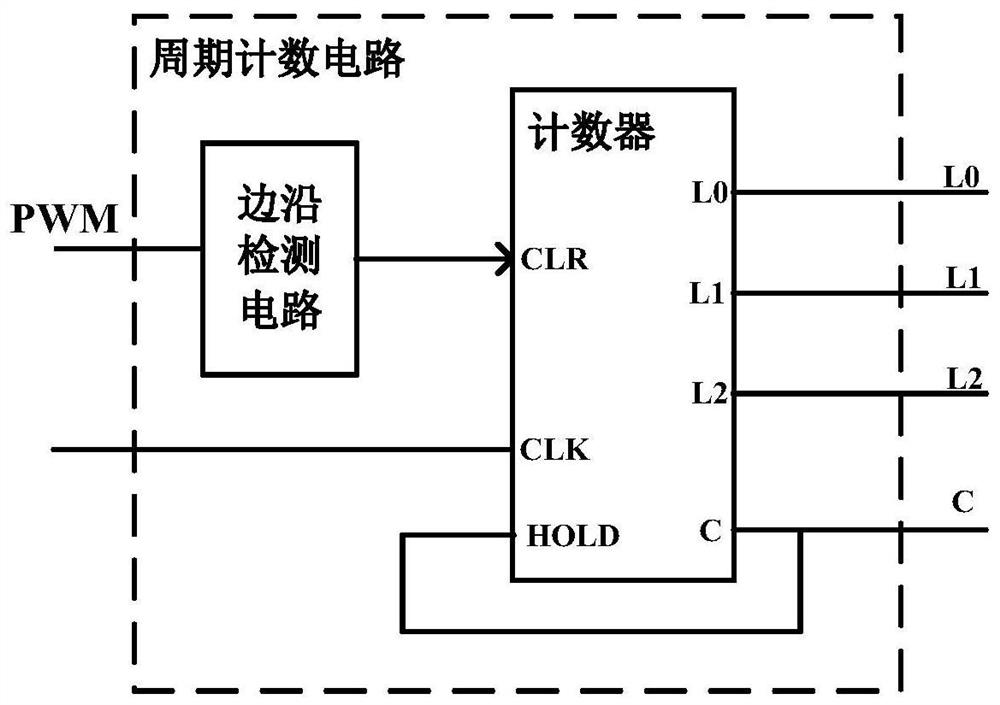

A programmable high-precision dynamic driving gan circuit and its application

ActiveCN111404526BMultiple choiceMeet the expected driving waveformEfficient power electronics conversionElectronic switchingHemt circuitsPhysics

The invention belongs to the field of power semiconductor device switches, and specifically relates to a programmable high-precision dynamic driving GaN circuit and its application. The circuit includes a programmable digital module, a clock generation module and a driving module; the programmable digital module includes an EEPROM readout circuit, Register circuit, logic control circuit; drive circuit includes rough drive circuit and fine drive circuit. The turn-on and turn-off times are equally divided into multiple time periods, and each time period is a rough driving cycle; fine-tuning of the fine driving can be performed once in each rough driving cycle to generate pulses to control the driving current of the fine driving circuit. After power-on, the off-chip data is stored in the register through the EEPROM readout circuit, and the oscillator circuit controls the logic circuit to transmit the required data to the drive circuit during the turn-on and turn-off process, and dynamically controls the rough drive circuit and the rough drive circuit of multiple rough drive cycles. Fine drive circuit to realize programmable high-precision active GaN gate control.

Owner:HUAZHONG UNIV OF SCI & TECH

Machining equipment capable of realizing accurate machining

ActiveCN105922050AGuaranteed normal transmissionGuaranteed drive accuracyMetal working apparatusPush and pullReciprocating motion

The invention relates to machining equipment capable of realizing accurate machining. The machining equipment comprises a rack (8) and a machining head (9) arranged on the rack (8) in a way of reciprocating along a forward and backward direction. A sliding chute cavity (90) extending along a forward and backward direction is formed in the machining head (9), and is used for matching with a roller driving device in a rolling way, so that the roller driving device can push and pull the machining head to adjust the position, orthogonal to the forward and backward direction, in a left-right direction, of the machining head, wherein the roller driving device comprises a threaded sleeve piece (82) rotatably arranged on the rack (8) and used for being in threaded fit with a threaded moving rod (83).

Owner:中山特云智慧控制技术研究有限公司

Mechanical machining device capable of achieving reciprocating machining

ActiveCN105855915AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusLarge fixed membersPush and pullReciprocating motion

The invention discloses a mechanical machining device capable of achieving reciprocating machining. The mechanical machining device comprises a rack (8) and a machining head (9) capable of being installed on the rack (8) in the mode of being capable of doing reciprocating motion in the front and back direction, a sliding groove cavity (90) extending in the front and back direction is formed in the machining head (9) and used for being in rolling fit with a rolling wheel pushing device, and then the rolling wheel pushing device pushes and pulls the machining head (9) to adjust the position of the machining head (9) in the left and right direction orthogonal to the front and back direction, wherein the rolling wheel pushing device comprises a threaded sleeve part (82) which is rotatably installed on the rack (8) and used for being in screw-thread fit with a threaded moving rod (83).

Owner:天长市奥威机电设备有限公司

Optical device rotation angle detection method, rotation angle detection device and camera module

ActiveCN112146560AReduce the complexity of the bending processGuaranteed machining accuracyPrintersProjectorsCamera moduleMechanical engineering

The embodiment of the invention provides an optical device rotation angle detection method, a rotation angle detection device and a camera module, and relates to the technical field of optical anti-shake. The optical device rotation angle detection method comprises the steps of detecting the rotation angle of an optical device around a first axis; acquiring a first Hall value output by a first position sensor, and acquiring a second Hall value output by a second position sensor; calculating the difference between the first Hall value and the second Hall value to obtain a Hall difference value;and determining the angle of the optical device when the optical device rotates around the first axis according to the corresponding relation between the Hall difference value and the rotation anglevalue of the optical device, wherein a second axis is perpendicular to the first axis.

Owner:HUAWEI MACHINERY

Mechanical processing device with processing head capable of performing reciprocating motion

InactiveCN106002434AGuaranteed normal transmissionGuaranteed driving accuracyFeeding apparatusMetal working apparatusPush and pullReciprocating motion

The invention discloses a mechanical processing device with a processing head capable of performing reciprocating motion. The mechanical processing device comprises a rack (8) and the processing head (9) which is mounted on the rack (8), capable of performing reciprocating motion in the front-and-back direction, wherein a sliding groove cavity (90) which extends in the front-and-back direction is formed in the processing head (9); the sliding groove cavity (90) is in rolling cooperation with a roller pushing device, so that the roller pushing device pushes and pulls the sliding groove cavity to adjust the position of the sliding groove cavity in the left-right direction orthogonal to the front-and-back direction; and the roller pushing device comprises a threaded sleeve part (82) which is rotatably mounted on the rack (8) and is in thread fit with a threaded moving rod (83).

Owner:广东诚泰精工机械有限公司

A processing device capable of reciprocating movement of a processing head

ActiveCN105881041BGuaranteed normal transmissionGuaranteed drive accuracyFeeding apparatusLarge fixed membersReciprocating motion

A machining device with a machining head capable of reciprocal motion comprises a rack (8) and the machining head (9) which is arranged on the rack and capable of moving reciprocally in the anterior and posterior direction. A sliding groove cavity (90) which extends in the anterior and posterior direction is formed in the machining head (9). The sliding groove (90) is used for scrollably matching a roller pushing device to adjust the position in the left and right direction which intersects with the anterior and posterior direction by pushing and pulling of the roller pushing device, wherein the roller pushing device comprises a threaded sleeve part (82) which is rotationally installed on the rack (8) to match the thread of a threaded moving rod (83).

Owner:JIANGSU MINGGE FORGING EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com