Protection type four-rail support assembly for horizontal coarse framing machine

A technology of supporting components and rough frame machines, which is applied in the direction of maintenance and safety accessories, metal processing machinery parts, large fixed members, etc., can solve the problems of not being able to process heavy workpieces, increasing the manufacturing cost of the protective cover, and difficult expansion and contraction of the protective cover. Achieve the effect of increasing the smoothness of movement, light overall weight and reducing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

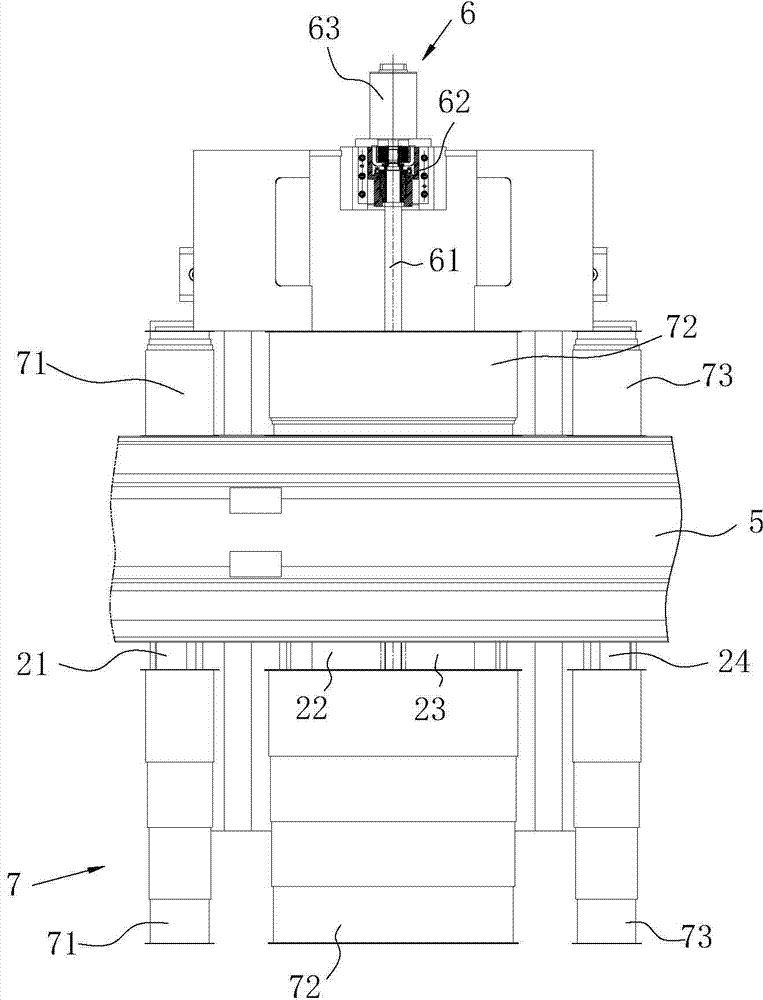

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

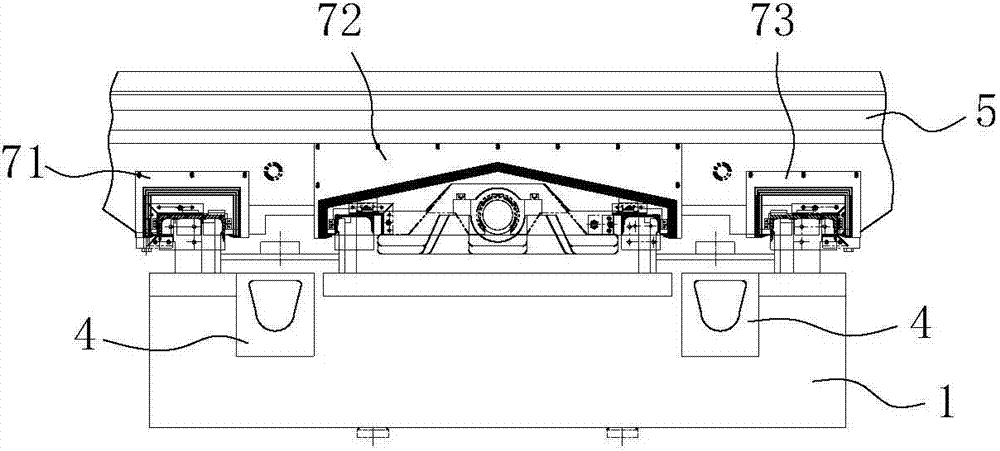

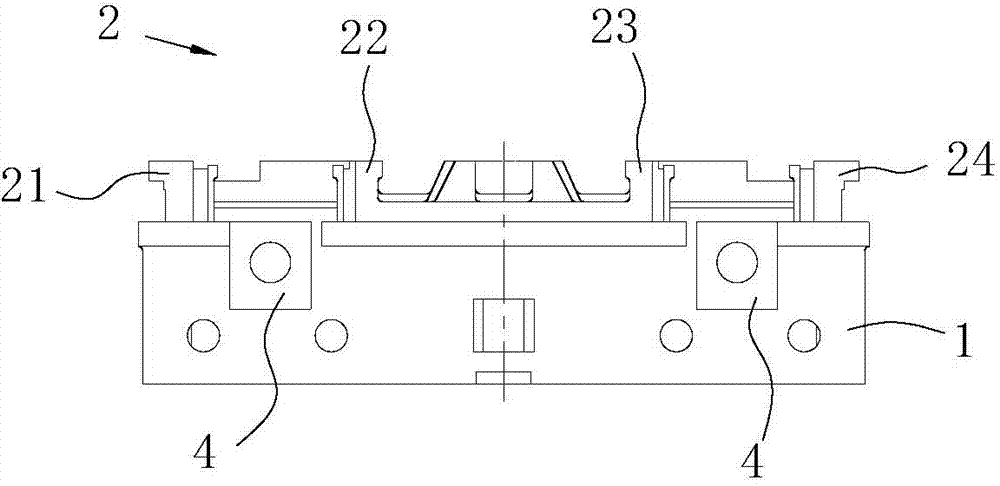

[0039] like Figures 1 to 4 As shown, the protective four-rail support assembly for a horizontal rough frame machine in this embodiment includes a base 1, on which a driving platform 5 is slidably arranged, and the driving platform 5 is placed on the base 1 along the length direction of the base 1 through the driving mechanism 6. move.

[0040] Four guide rails 2 parallel to each other are fixedly arranged on the base 1 along its length direction, which are the first guide rail 21, the second guide rail 22, the third guide rail 23 and the fourth guide rail 24 arranged in sequence, and the guide rails 2 and the base 1 are integrally cast. , between the second guide rail 22 and the third guide rail 23, the receiving groove 3 opened along the length direction of the base 1, between the first guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com