High-precision valve actuator

A driver, high-precision technology, applied in the direction of valve details, valve devices, engine components, etc., can solve the problems of long closed-loop control time, poor valve driving accuracy, difficult disassembly and maintenance, etc., to reduce maintenance costs, ensure driving accuracy, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention will be further described in detail below with reference to the examples and figures, but the embodiments of the present invention are not limited thereto.

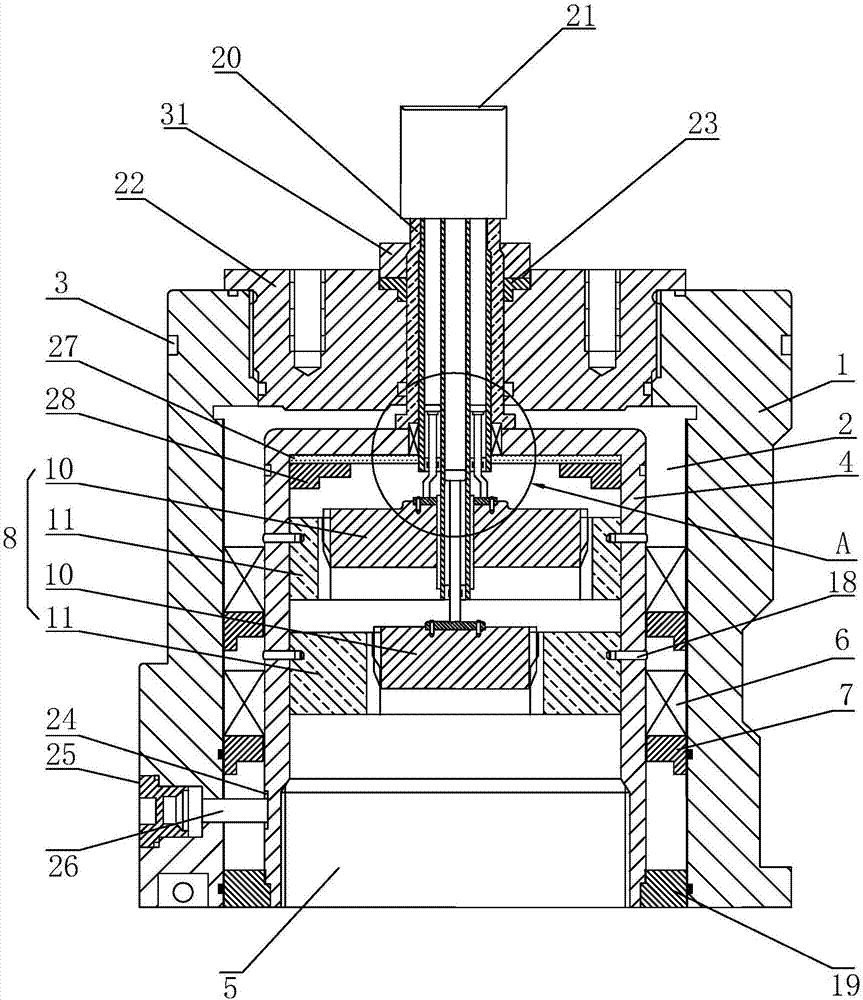

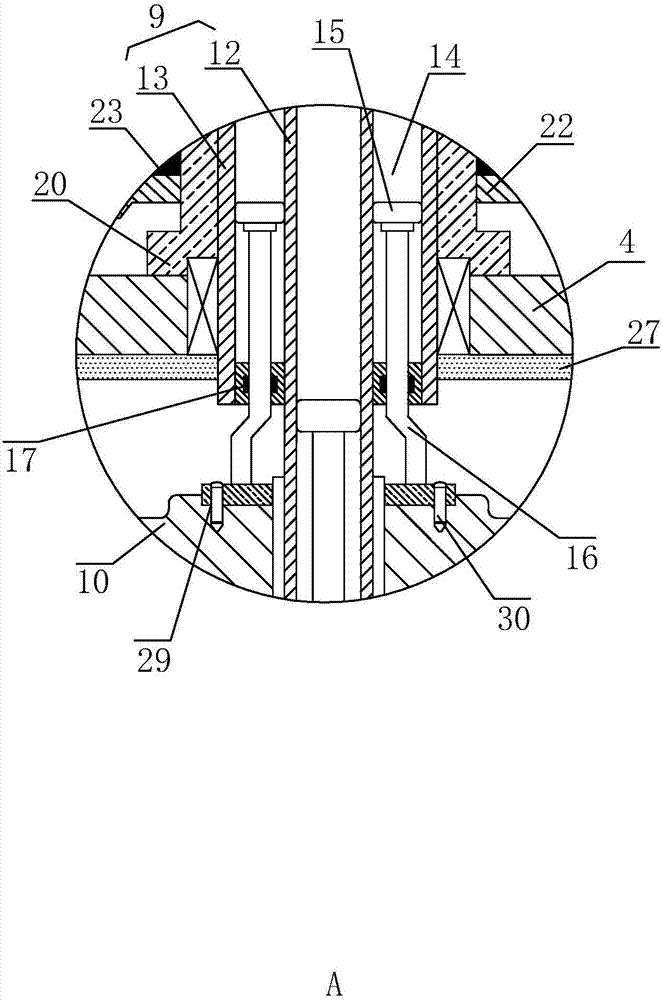

[0039] Such as figure 1 As shown, a high-precision valve driver includes a housing 1, and a cylindrical cylindrical groove 2 is opened in the housing 1 along its length direction, and the cylindrical groove 2 forms an opening at one end of the housing 1. A hoisting hole 3 is provided on the outer wall of the housing 1 . A sleeve 4 is sleeved coaxially in the cylindrical groove 2 . The end of the sleeve 4 away from the opening of the housing 1 is the driving connection part, and the end close to the opening of the housing 1 is the clamping part. The driving connecting part is connected with a secondary helical gear set, and the inner wall of the clamping part is provided with a valve The shape of the valve stem matches the clamping groove 5. When in use, one end of the valve stem directly ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com