Permanent magnet suspension slide guide for mini-type machine tool

A magnetic levitation and miniature technology, applied in the direction of large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problem of inability to take into account the transmission accuracy and flexible magnetic control, to ensure the accuracy of the guide rail drive, avoid friction, resist the outside world The effect of force interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

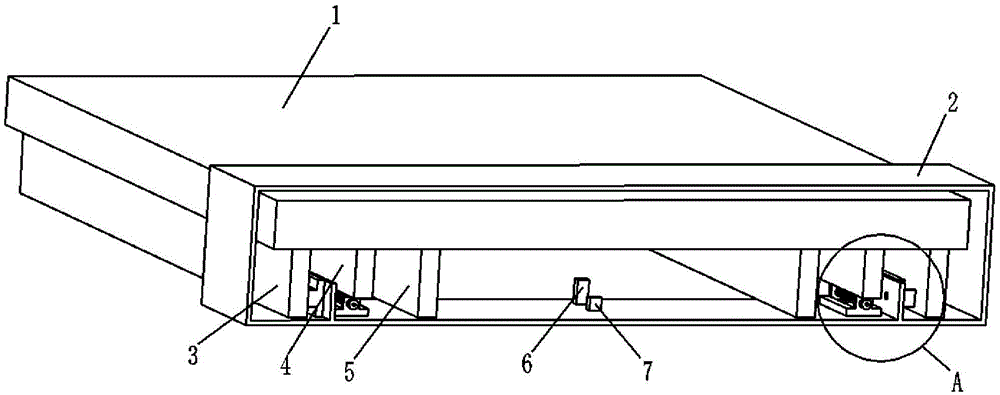

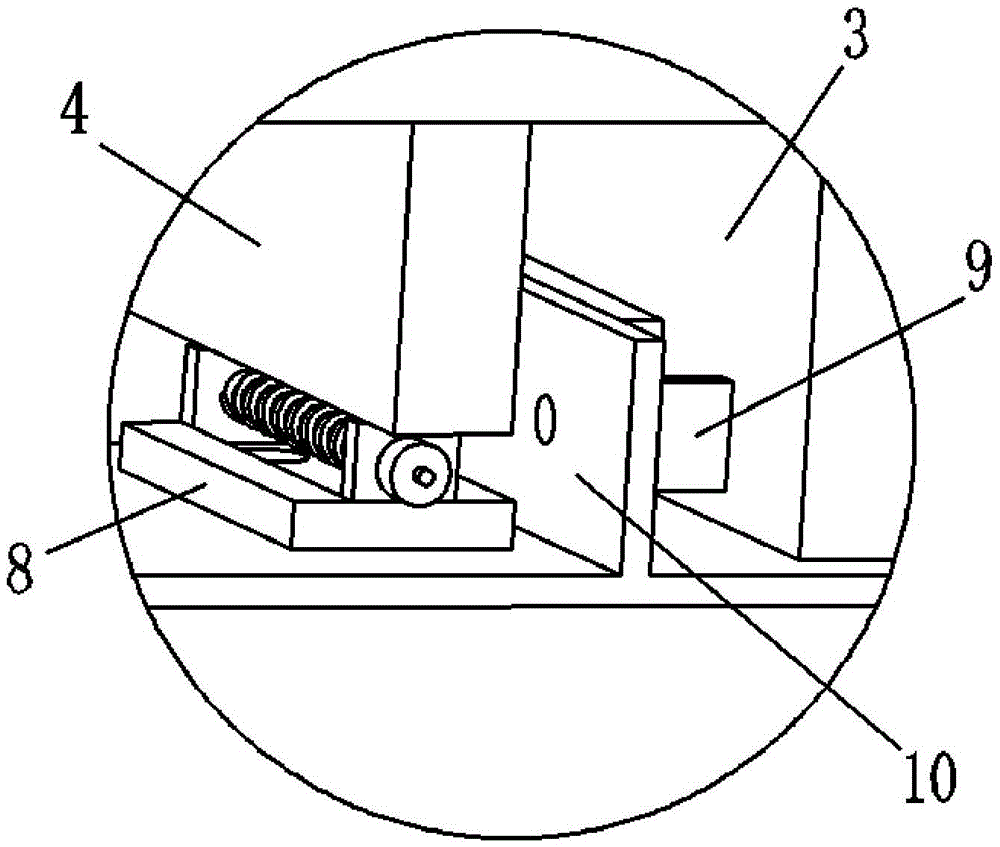

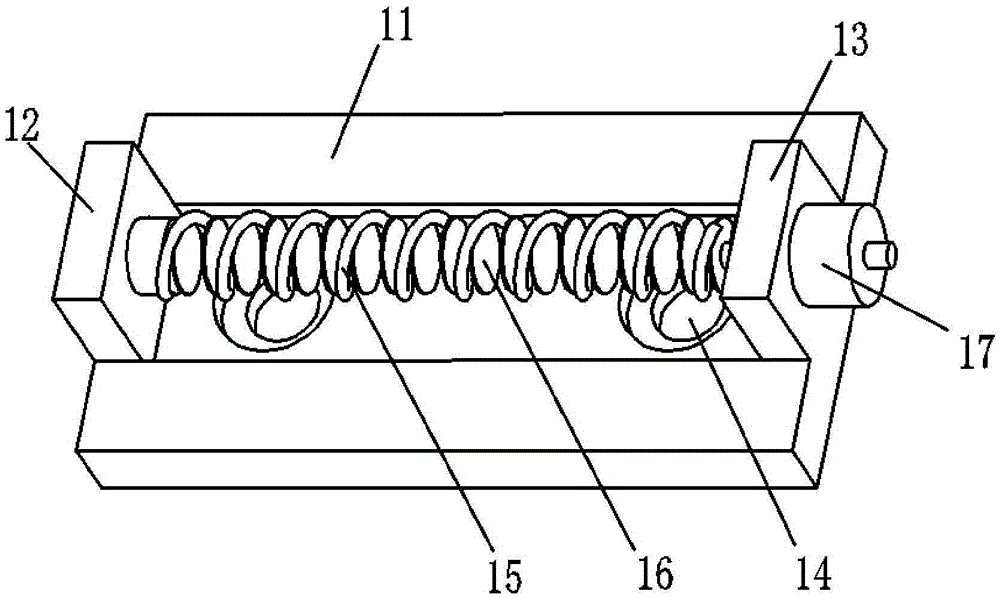

[0016] refer to figure 1 , figure 2 , image 3 and Figure 4 , the guide rail of the permanent magnetic levitation micro-machine tool of the present invention includes a fixed base 1, a suspension bracket 2, a vertical magnetic regulator 8, a horizontal magnetic regulator 9, a vertical ranging sensor 6 and a horizontal ranging sensor 7; both sides of the fixed base 1 A horizontal magnetic anchor 3, a vertical magnetic anchor 4, and a horizontal ranging anchor 5 are arranged symmetrically from the outside to the inside; the suspension bracket 2 is a closed square ring structure, the top is a working platform 21, and the bottom is a supporting platform 22. The left and right sides of the support platform 22 are symmetrically provided with a horizontal magnetic adjustment bracket 10; the horizontal magnetic adjustment 9 is fixed on the horizontal magnetic adjustment bracket 10 by screws, and the vertical magnetic adjustment 8 is fixed on the horizontal magnetic adjustment by s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com