Device for preparing pile-rock interface compression shear sample and use method

A sample preparation and interface technology, applied in the field of geotechnical engineering rock-socketed pile pile-rock contact surface, can solve the problems of not considering the penetration force of concrete to surrounding rock, errors, etc., achieve low cost, reduce operation links, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

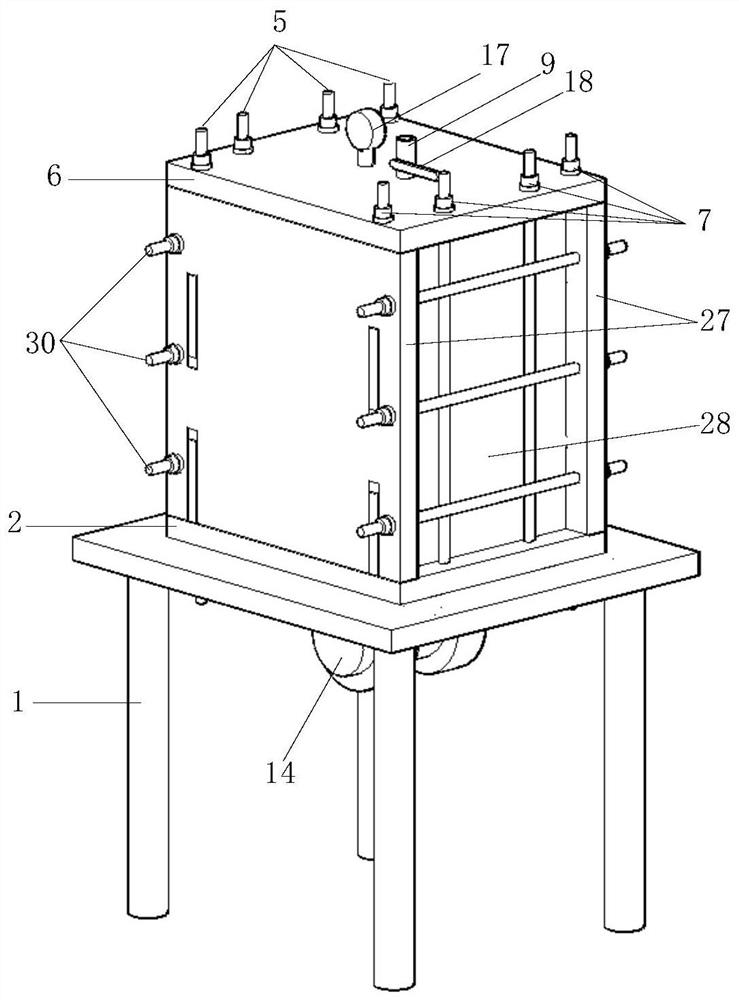

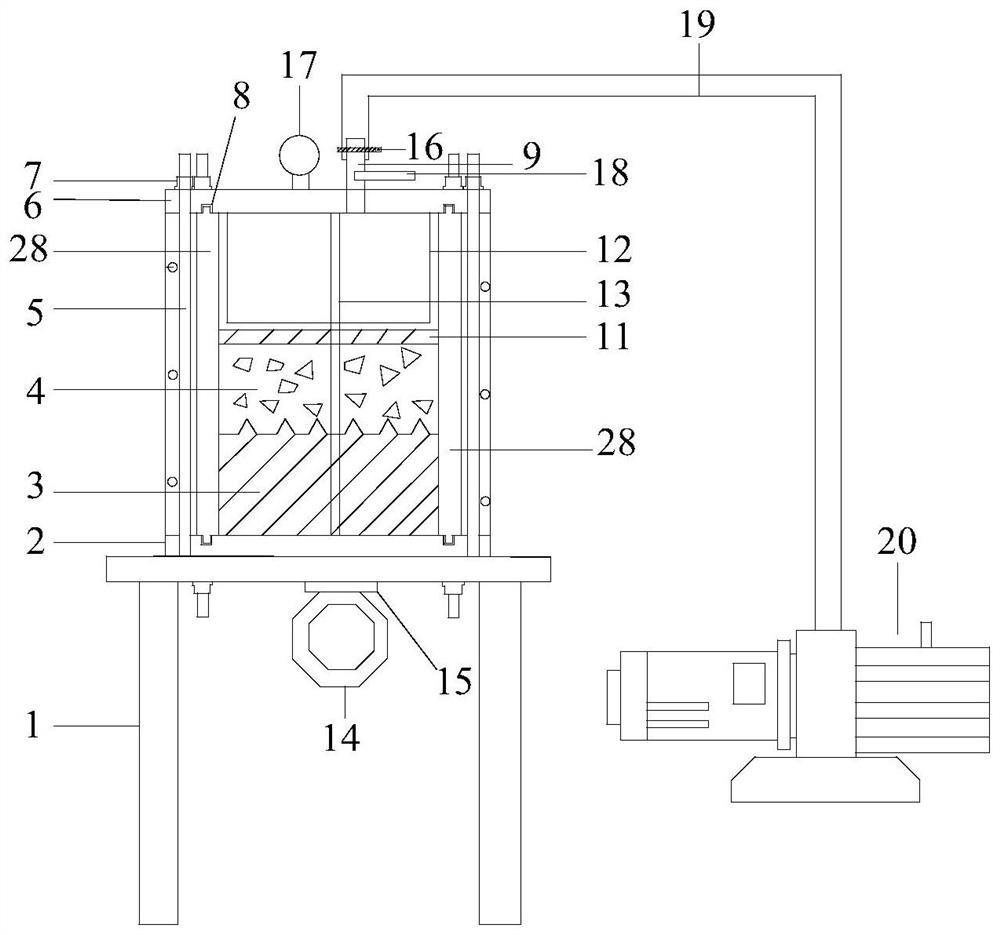

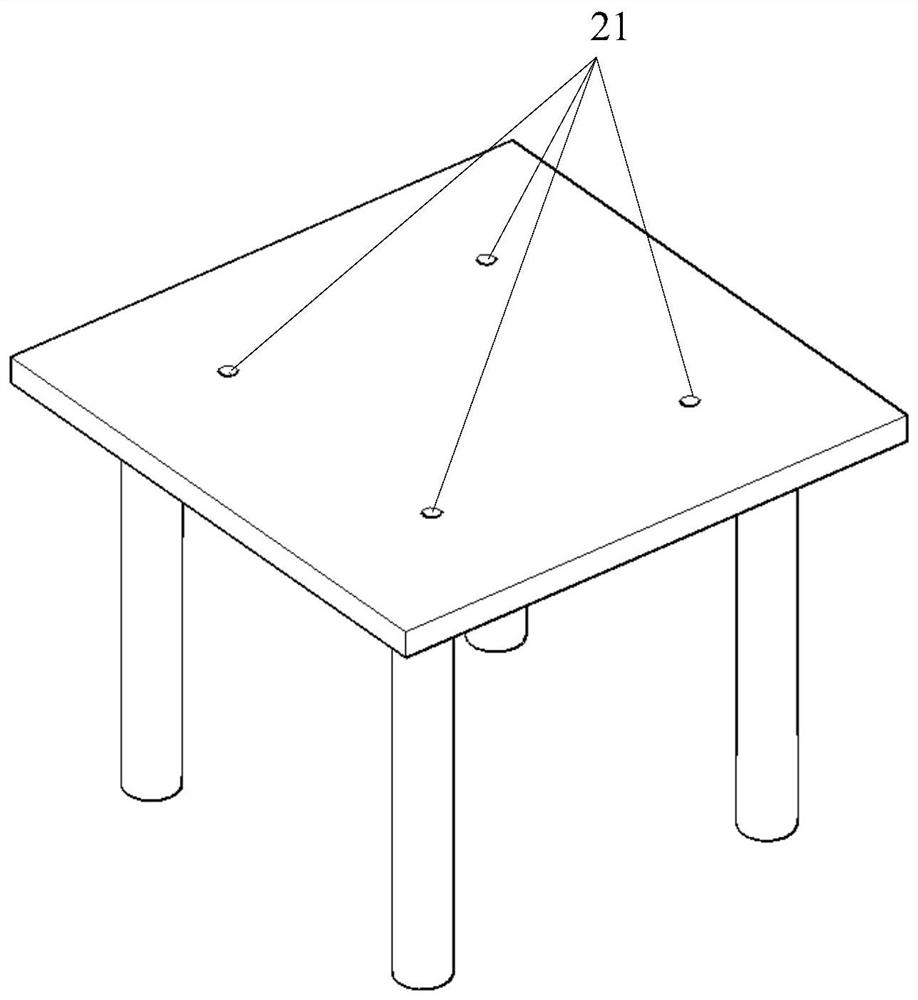

[0037] see Figure 1 to Figure 3 , the present embodiment provides a device for preparing a pile-rock interface compression shear sample, including a working platform 1, a flat-plate attached vibrator 14, a base 2, A steel formwork 27, B steel formwork 28, and a sealing cover 6. The air compressor 20 and the air pipeline 19, the base 2 and the sealing cover 6 are provided with four grooves 22 and eight fixing holes 21, the grooves 22 are embedded with a sealing strip 8, the The bottom of the A steel formwork 27 and the B steel formwork 28 and the raised parts 10 at the top are all embedded in the inside of the groove 22, and the working platform 1, the base 2, the A steel formwork 27, the B steel formwork 28 and the sealing cover 6 pass through The horizontal fixing rod 30 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com